Folding and pasting machine control system and control method thereof

A technology of control system and control method, which is applied in box making operation, container manufacturing machinery, rigid/semi-rigid container manufacturing, etc., can solve problems such as glue drying and crusting, affecting bonding effect, and gluing wheel stoppage, etc. , to avoid dry skinning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

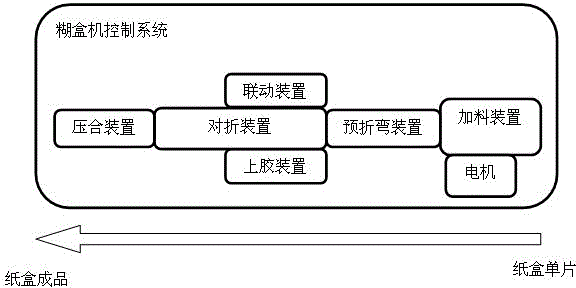

[0016] see figure 1 As shown, the present invention provides a folder-gluer control system, which includes sequentially connected feeding devices, a pre-bending device connected to the feeding device, a half-folding device connected to the pre-bending device, and gluing devices located on both sides of the half-folding device And the linkage device, the pressing device located at the rear end of the folding device, and the motor connected and driving the aforementioned various devices.

[0017] The feeding device is used to add the die-cut product (i.e. the single piece of carton) to realize the feeding process. The design is processed, and then transported to the folding device for half-folding treatment, so that the single piece of the carton is preliminarily formed into the prototype of the box body, and finally the box body is transferred to the pressing device, and the prototype of the box body is pressed by the pressing device processing, and finally form the finished b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com