Composite flavoring and production method thereof

A technology of flavor seasoning and production method, applied in the field of seasoning, can solve the problems of lack of nutrients, single flavor and aroma, and achieve the effects of good flavor, good product quality, and improvement of technical level and market competitiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Take 10 grams of dried Cordyceps militaris and add it to 200 milliliters of water, soak for 60 minutes, add 1200 grams of clean chicken into the soaking liquid, then add 6000 milliliters of water, heat and cook. Pick up the cooked chicken and Cordyceps militaris and crush it with a meat grinder, mix it with the juice and put it into a colloid mill to grind it into a slurry, microwave it for 10 seconds, adjust the pH value to 8.5 with NaOH solution, and hydrolyze it at 90°C 2 hours; use citric acid solution to adjust the pH of the hydrolyzate to 8.5, add 0.1% alkaline protease of chicken mass, and enzymolyze at 60°C for 6 hours, add to every 100ml of enzymolysis mixture: 0.5g leucine, 0.8 g cysteine, 6g sucrose, 12g monosodium glutamate, 1g maltodextrin, 0.02g ascorbic acid, 12g salt, 1.0g I+G, 0.003g BHT, stir well and heat at 80°C for 6 hours to obtain compound flavor seasoning material.

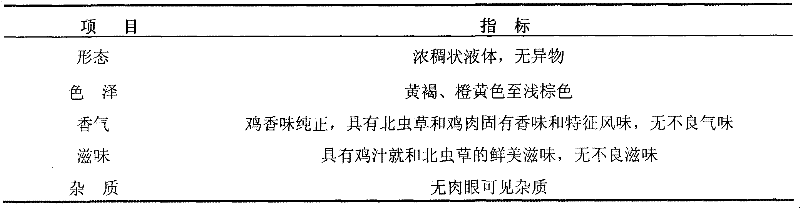

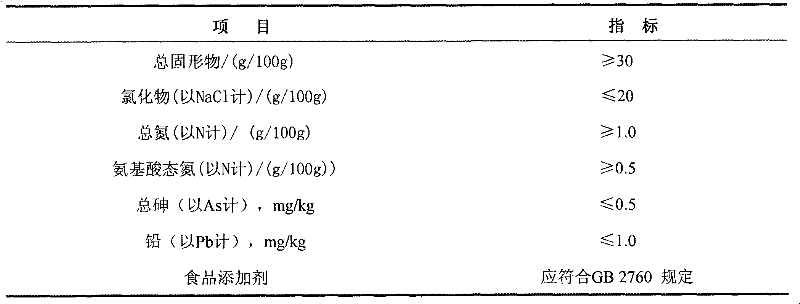

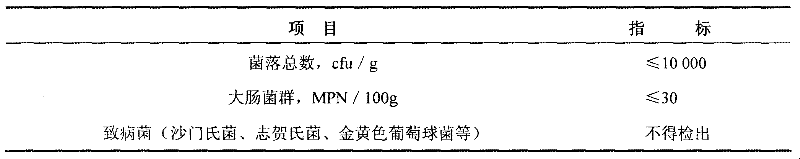

[0042] The compound flavor seasoning conforms to the commercial standard for ch...

Embodiment 2

[0044] Take 30 grams of dried Cordyceps militaris and add it to 700 ml of water, soak for 60 minutes, add 4.5 kg of clean chicken into the soaking liquid, add 30,000 ml of water, heat and cook until cooked. Pick up the cooked chicken and Cordyceps militaris and crush them with a meat grinder, mix them with the juice and put them into a colloid mill to grind them into a slurry, microwave them for 20 seconds, adjust the pH value to 9.5 with NaOH solution, and hydrolyze at 95°C for 1.5 hours; Use citric acid solution to adjust the pH of the hydrolyzate to 8.5, add 0.2% alkaline protease of the mass of chicken, and enzymolyze at 60°C for 4 hours, and add: 0.6g leucine, 1.0g cysteine to every 100ml enzymolysis mixture amino acid, 5g sucrose, 8g monosodium glutamate, 3g maltodextrin, 0.01g ascorbic acid, 15g salt, 0.8g I+G, 0.001g BHT, stir well and heat at 92°C for 3 hours to obtain the compound flavor seasoning.

[0045] The compound flavor seasoning conforms to the commercial s...

Embodiment 3

[0047] Take 100 grams of dried Cordyceps militaris and add it to 3000 milliliters of water, soak for 60 minutes, add 20 kilograms of clean chicken legs to the soaking liquid, add 150000 milliliters of water, heat and cook. Pick up the cooked chicken and Cordyceps militaris and crush them with a meat grinder, mix them with the juice and put them into a colloid mill to grind them into a slurry, microwave them for 25 seconds, adjust the pH value to 8.5 with NaOH solution, and hydrolyze at 92°C for 2 hours; Use citric acid solution to adjust the pH of the hydrolyzate to 8.0, add 0.25% alkaline protease of the mass of chicken leg meat, enzymolyze at 60°C for 5 hours, add: 0.5g leucine, 0.8g half Cystine, 6g sucrose, 10g monosodium glutamate, 2g maltodextrin, 0.03g ascorbic acid, 12g salt, 1.0g I+G, 0.002g BHT, stir well and heat at 88°C for 4 hours to obtain the compound flavor seasoning.

[0048] The compound flavor seasoning conforms to the commercial standard for chicken juice s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com