Hydrocarbon compound synthesis reaction system and finely divided particle removal method

一种烃化合物、合成反应的技术,应用在液态烃混合物的制备、化学仪器和方法、分离方法等方向,能够解决液体燃料产品质量下降、催化剂劣化等问题,达到防止质量下降、容易保养的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Below, refer to Figure 1 ~ Figure 3 Preferred embodiments of the present invention will be described.

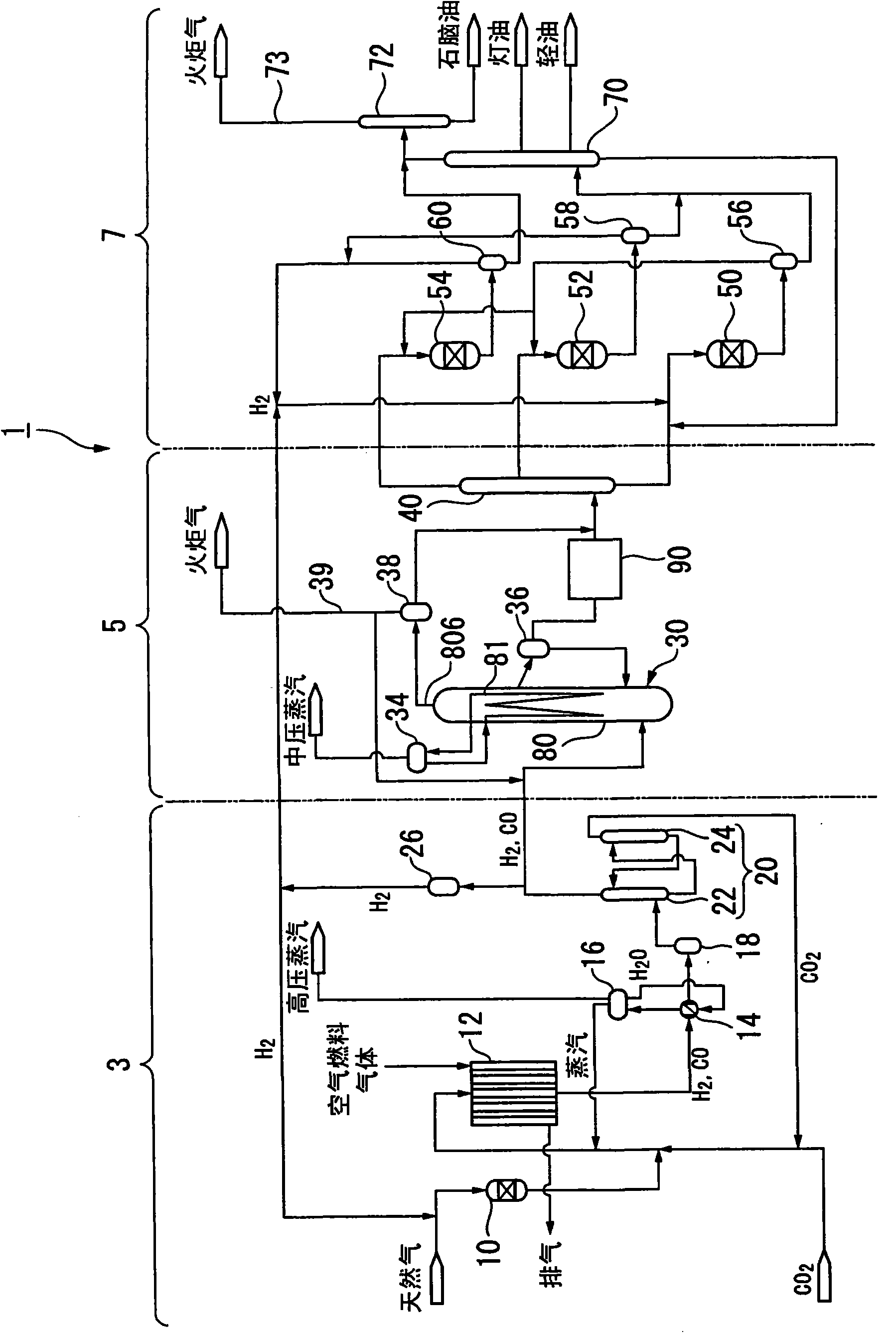

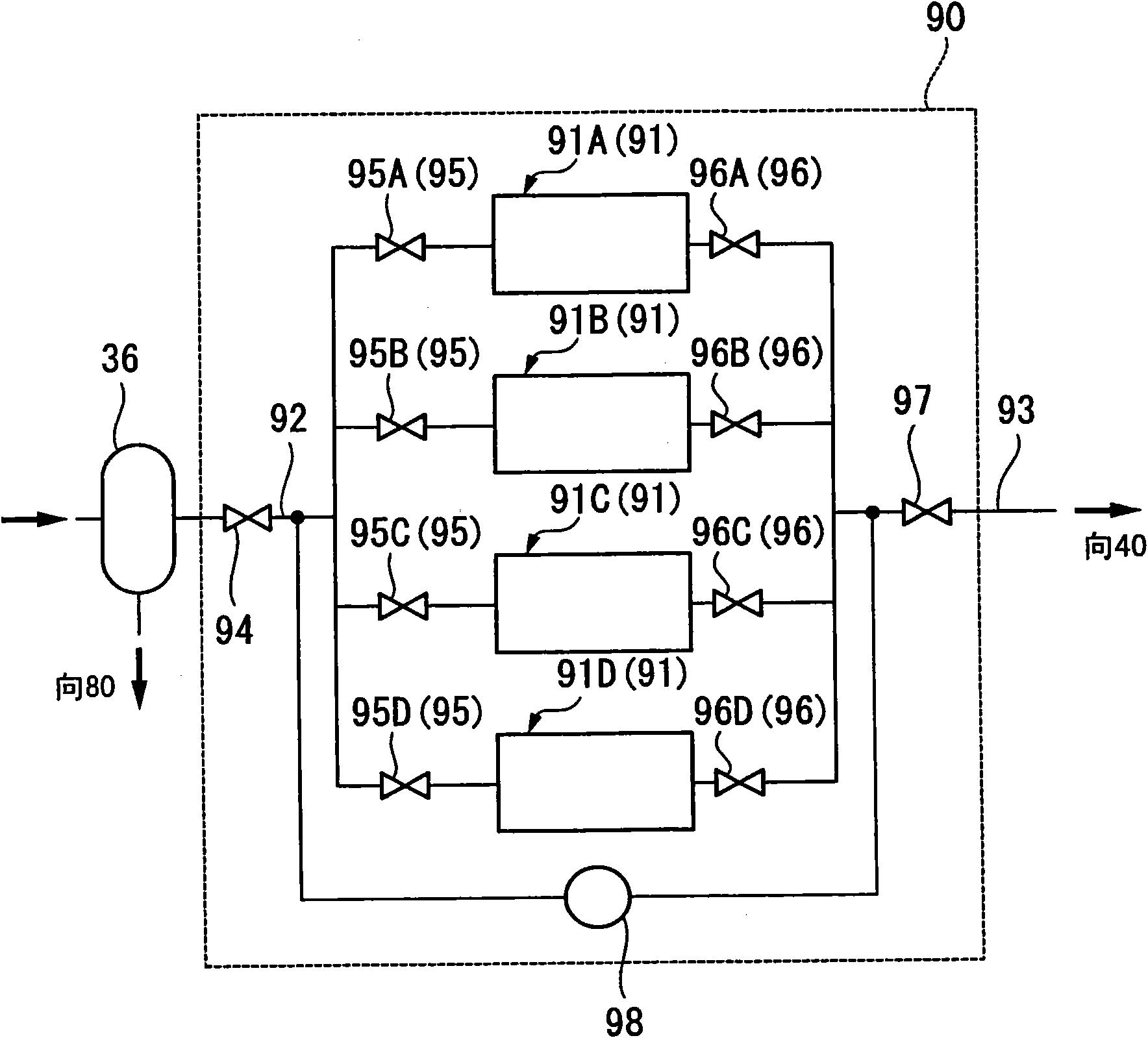

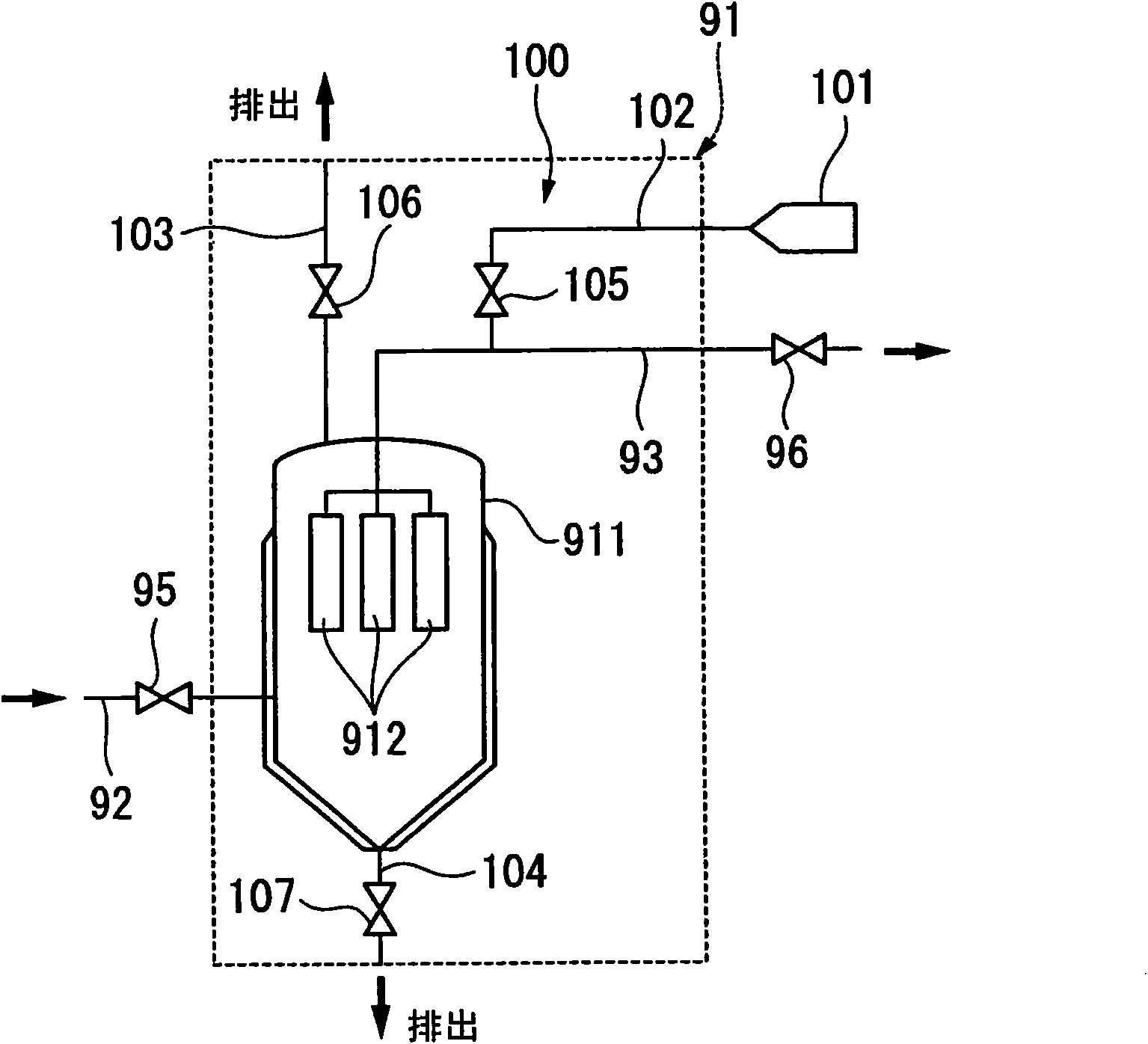

[0056] Such as figure 1 As shown, the liquid fuel synthesis system (hydrocarbon synthesis reaction system) 1 according to this embodiment is a plant for implementing a GTL process for converting hydrocarbon raw materials such as natural gas into liquid fuels. The liquid fuel synthesis system 1 is composed of a synthesis gas generation unit 3 , an FT synthesis unit 5 , and a product refining unit 7 . The synthesis gas generating unit 3 reforms natural gas as a hydrocarbon raw material to generate synthesis gas containing carbon monoxide gas and hydrogen gas. The FT synthesis unit 5 generates liquid hydrocarbons from the generated synthesis gas by a Fischer-Tropsch synthesis reaction (hereinafter referred to as "FT synthesis reaction"). The product refining unit 7 hydrotreats the liquid hydrocarbons produced by the FT synthesis reaction to produce liquid fuel produc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aperture size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com