Disconnectable mooring assembly

A mooring and uncoupling technology, which is applied in the direction of special-purpose ships, buoys, ships, etc., can solve the problems of troublesome connection inspection and maintenance, small space, increased load, etc., and achieve the effect of easy establishment and detachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

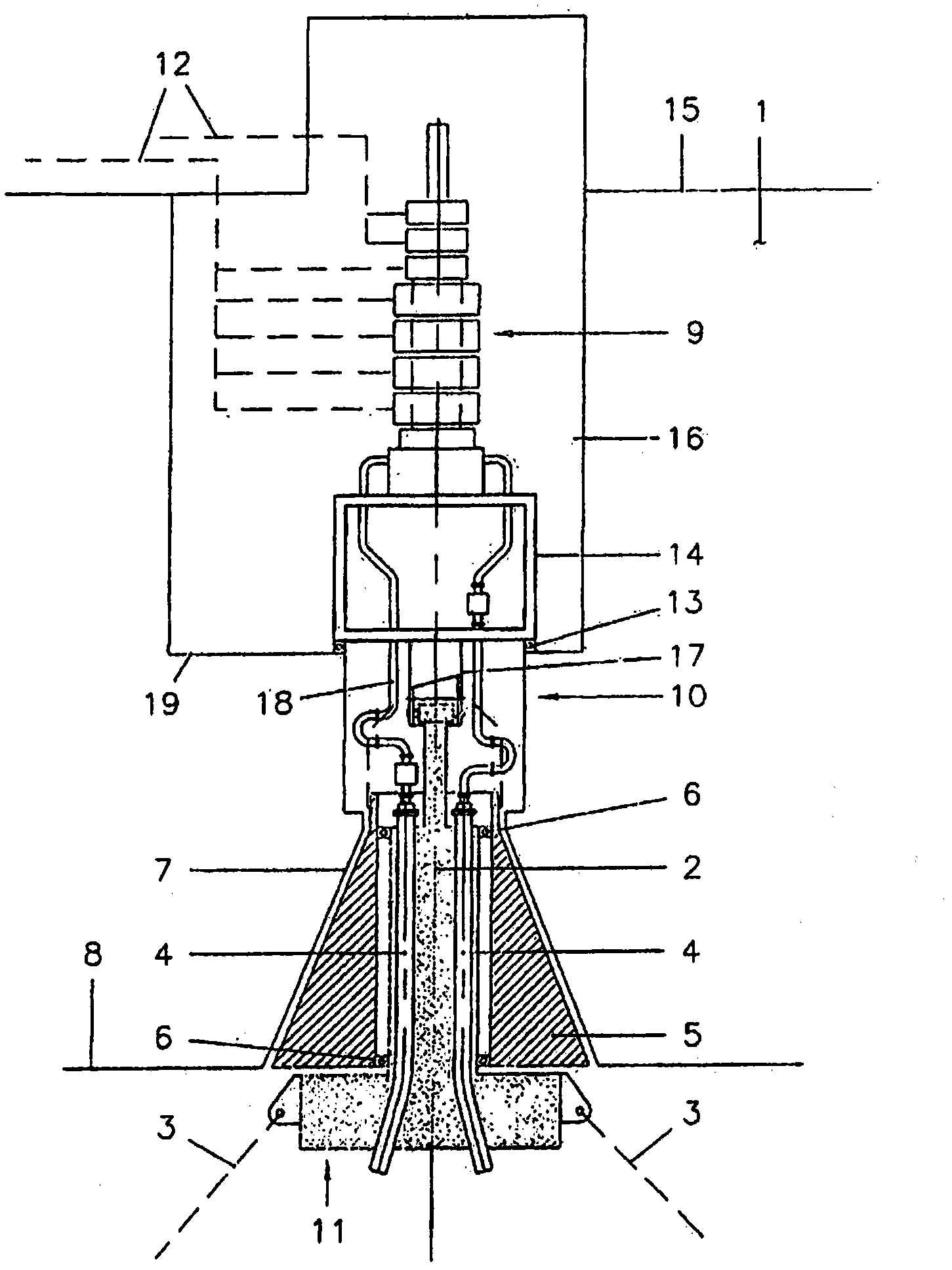

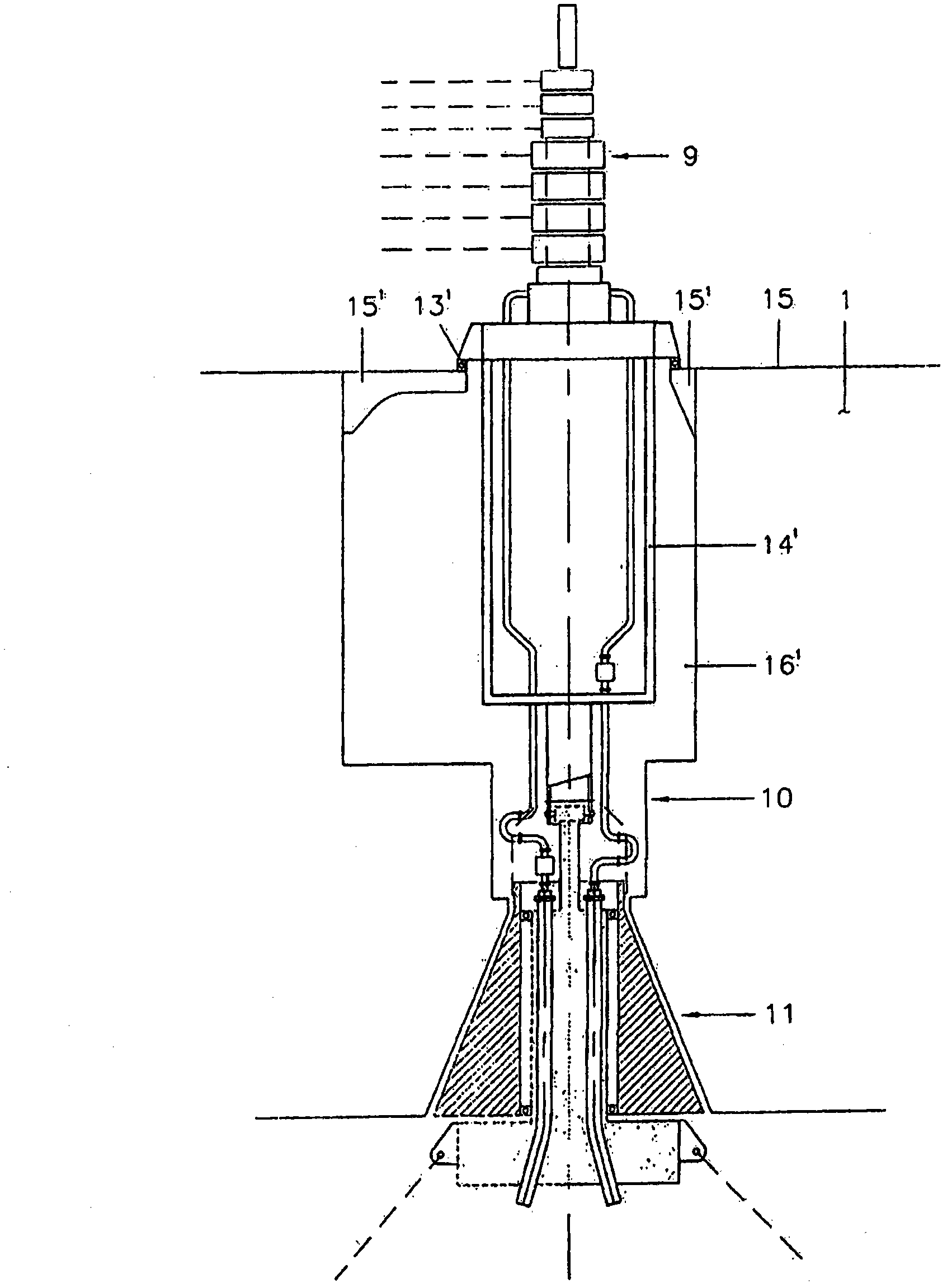

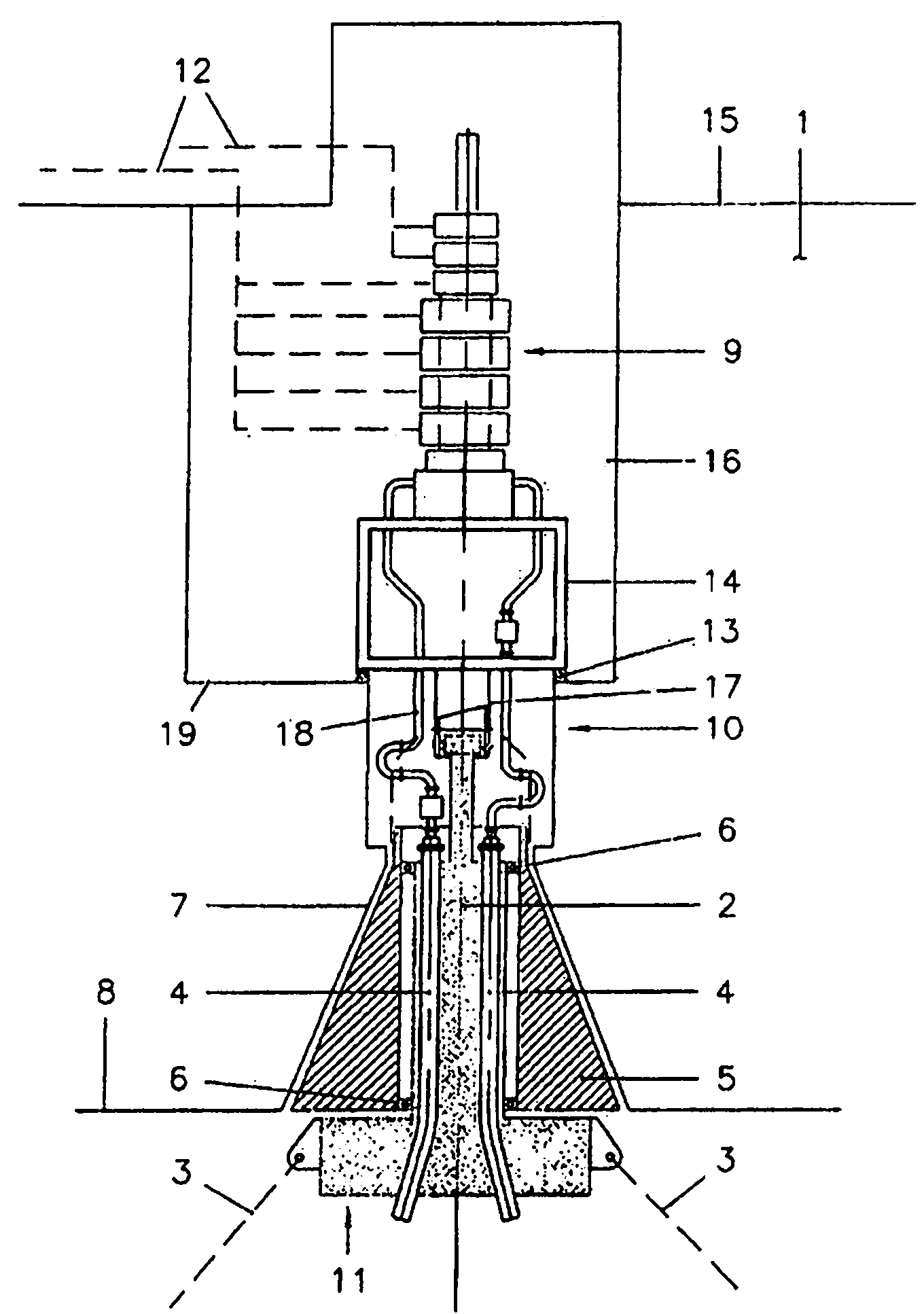

[0027] First reference figure 1 , figure 1 A detachable mooring assembly for a vessel 1 is shown. The detachable mooring assembly includes a mooring buoy 11, which is provided with a central component 2 for anchoring on the seabed through an anchor line 3, and the mooring buoy also includes a plurality of channels, each channel for Receiving riser 4. The riser can be connected to, for example, a subsea oil or gas well, and can be connected to the lower end of the mooring buoy, or can be (partially) pulled through the mooring buoy.

[0028] The mooring buoy 11 also includes an outer part 5 that surrounds the central part 2 and can rotate relative to the central part 2 (see, for example, the bearing assembly 6). The outer part 5 is adapted (by a suitable releasable locking device, which is not shown, but is known per se) to be accommodated and locked in the corresponding receiving opening 7 of the vessel 1 (usually but not exclusively, located in the vessel 1 In the keel 8 area)....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com