Probe positioning structure of four-probe instrument

A technology of positioning structure and tester, which is applied to the parts of electrical measuring instruments, measuring leads/probes, instruments, etc., can solve the problem that the positional accuracy of the four small holes is difficult to meet the requirements, the metal probe lacks constant pressure elasticity, Electric contact is difficult to guarantee and other problems, to achieve the effect of increasing strength, ensuring electrical insulation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

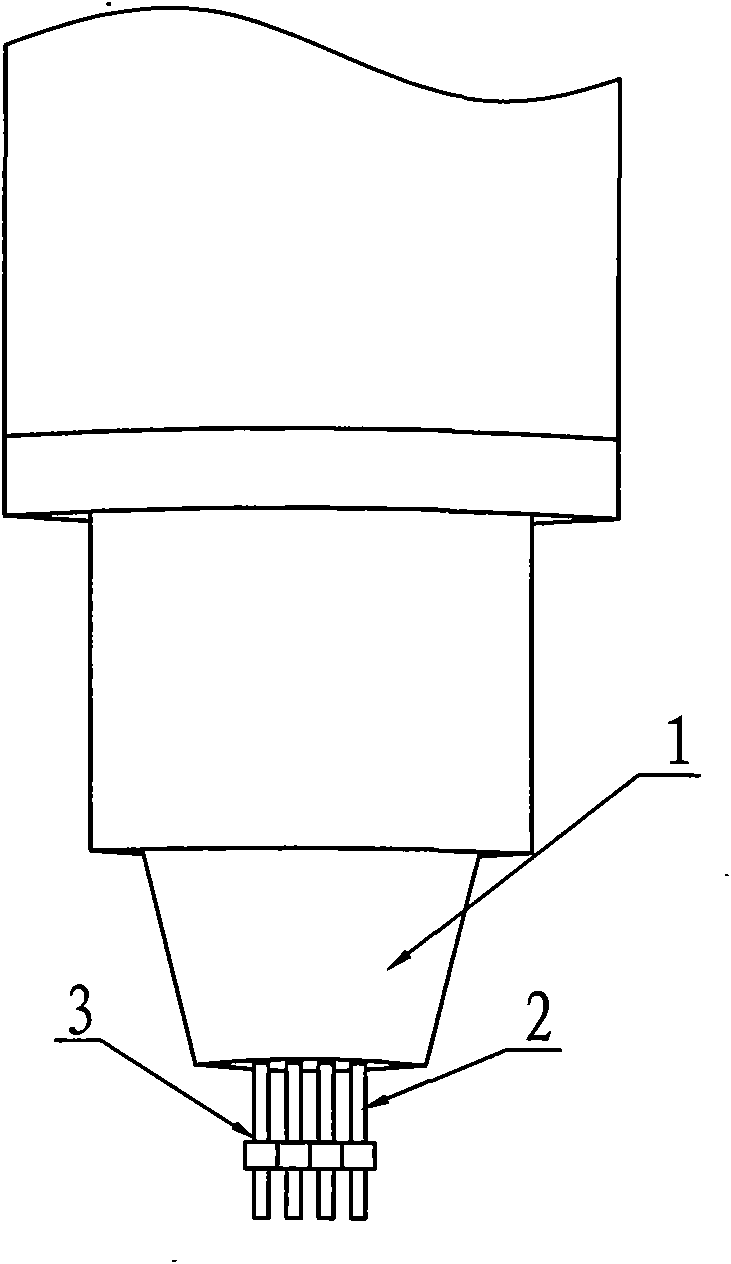

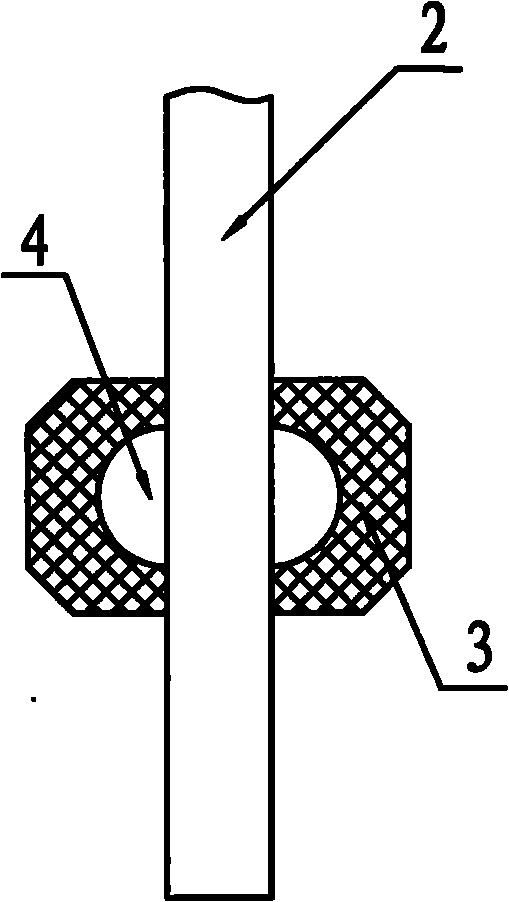

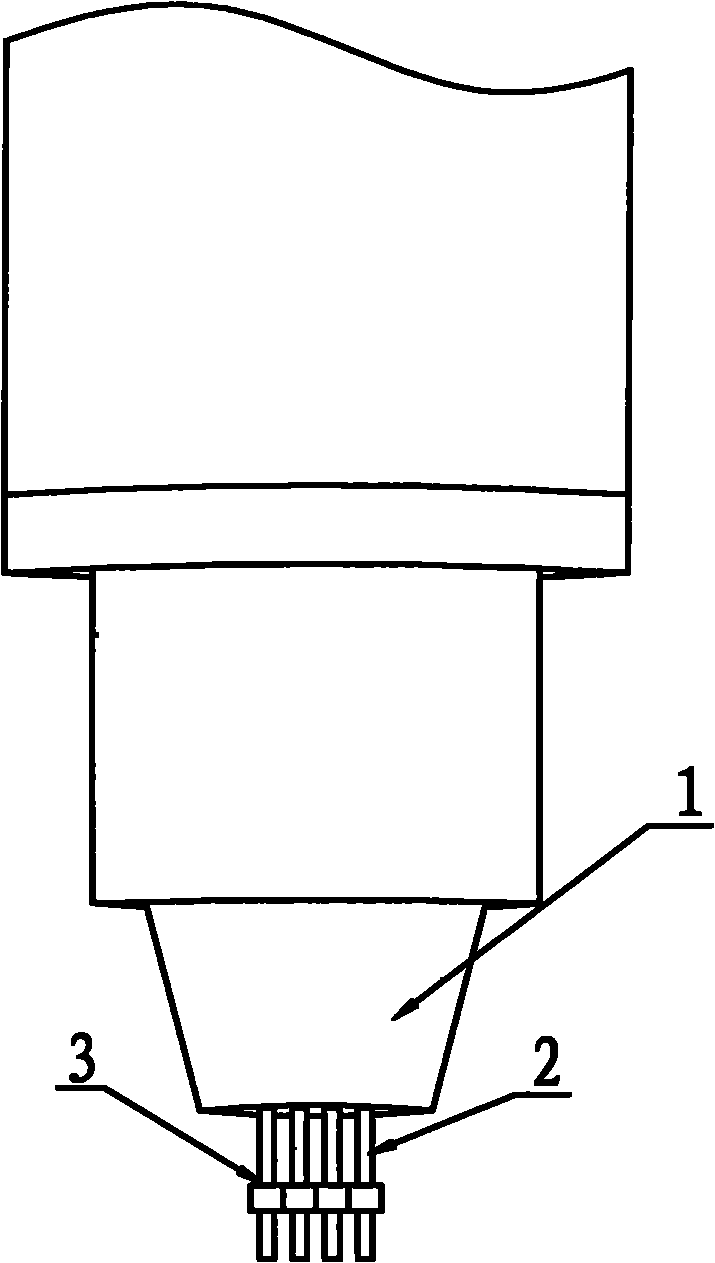

[0014] The probe positioning structure of the four-probe tester, such as figure 1 , figure 2 As shown, it includes an insulating probe 1 and four probes 2. The upper ends of the four probes 2 are solidified on the insulating probe 1, and each probe 2 is fixedly fitted with a molded PTFE insulating material. The elastic insulating spacer 3 formed, the inner diameter of the elastic insulating spacer 3 matches the diameter of the probe 2, and the sum of the wall thicknesses of the elastic insulating spacer 3 set on two adjacent probes 2 is equal to two phase The center distance between adjacent probes 2 minus the diameter of one probe 2; and the four elastic insulating spacers 3 are at the same height on the probe 2, the specific requirement is that the distance between the elastic insulating spacers 3 and the lower end of the metal probe 2 The distance is 1 / 4~1 / 2 of the total length of the probe 2, in this example 1 / 3, and the inner core of the elastic insulating spacer 3 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com