Underground in-situ emulsified explosive mixed charging vehicle

A technology for on-site mixing and emulsification of explosives is applied in the field of underground excavation and mining blasting charge devices. The ratio can be adjusted to ensure good health and the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

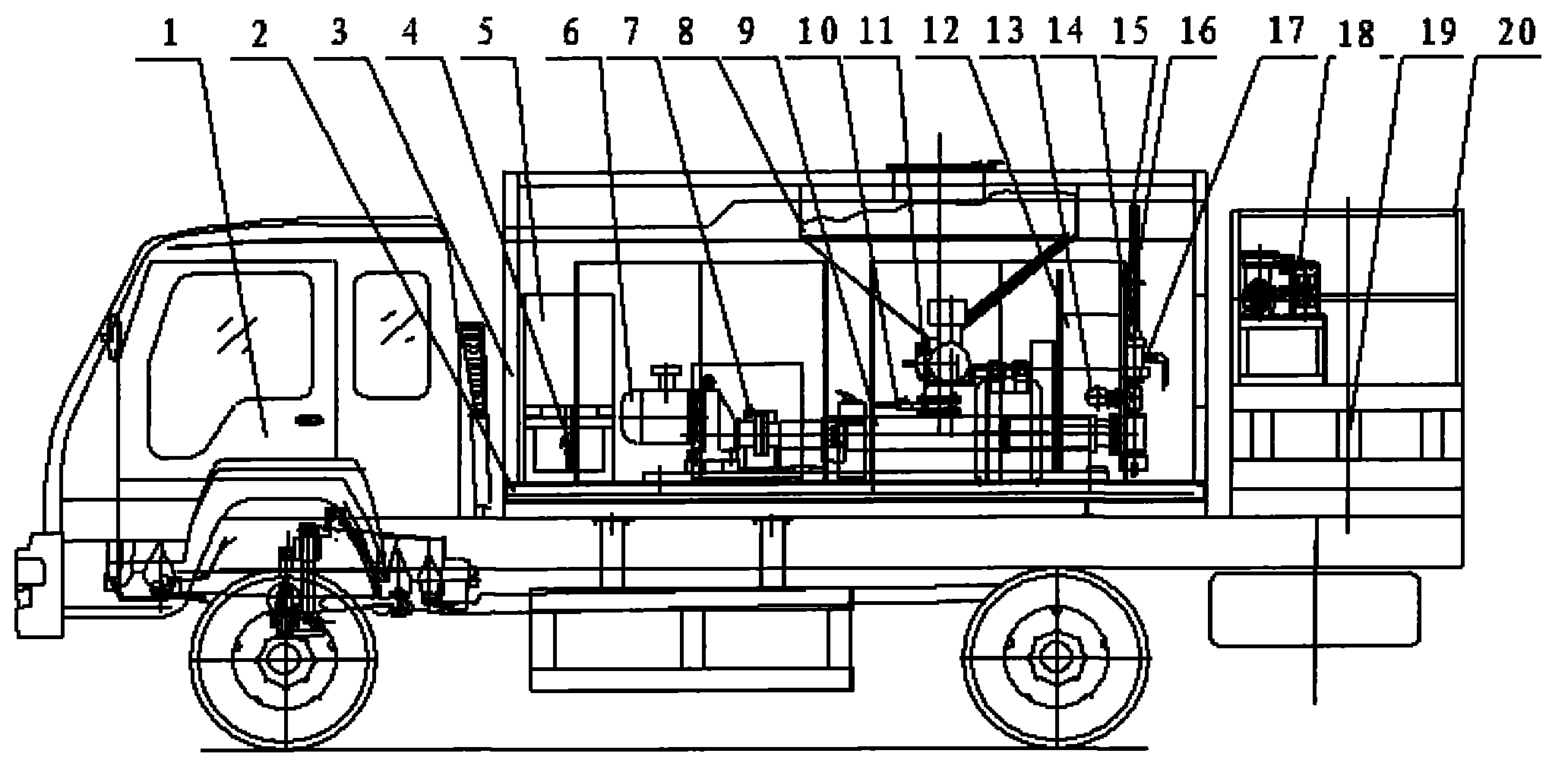

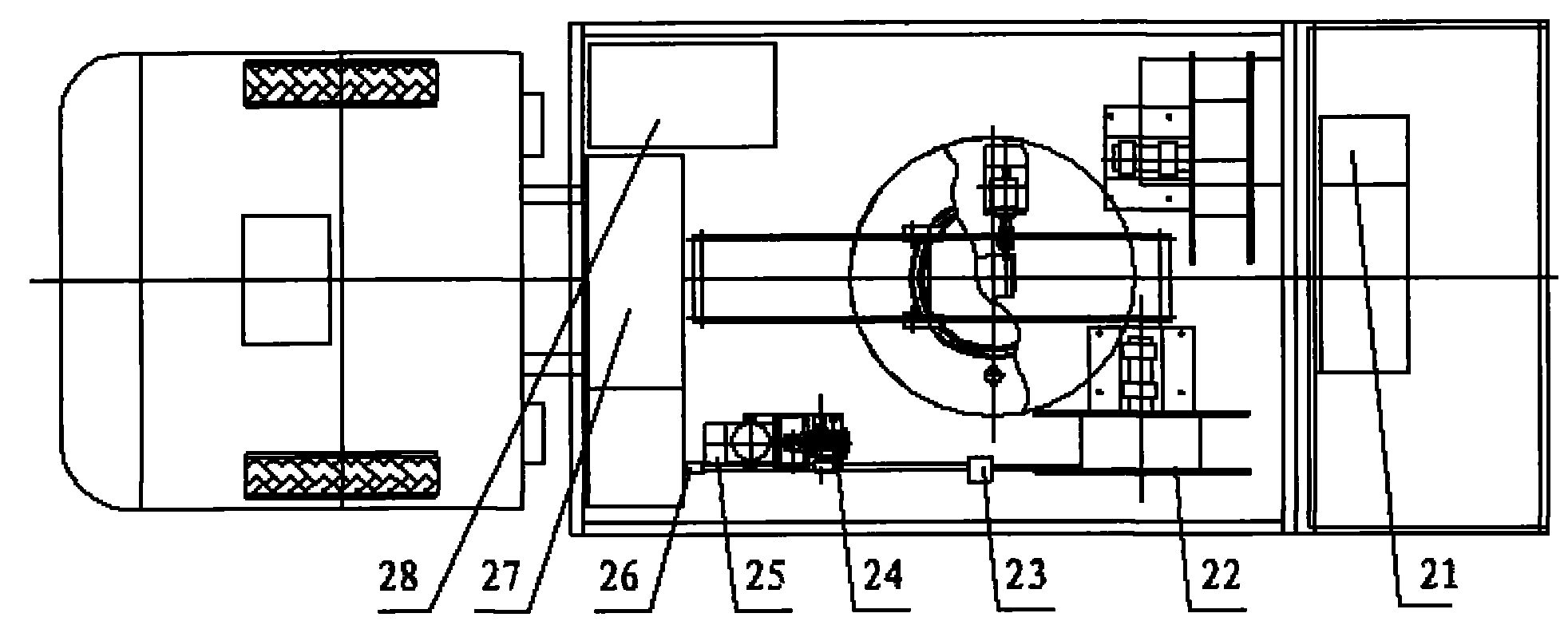

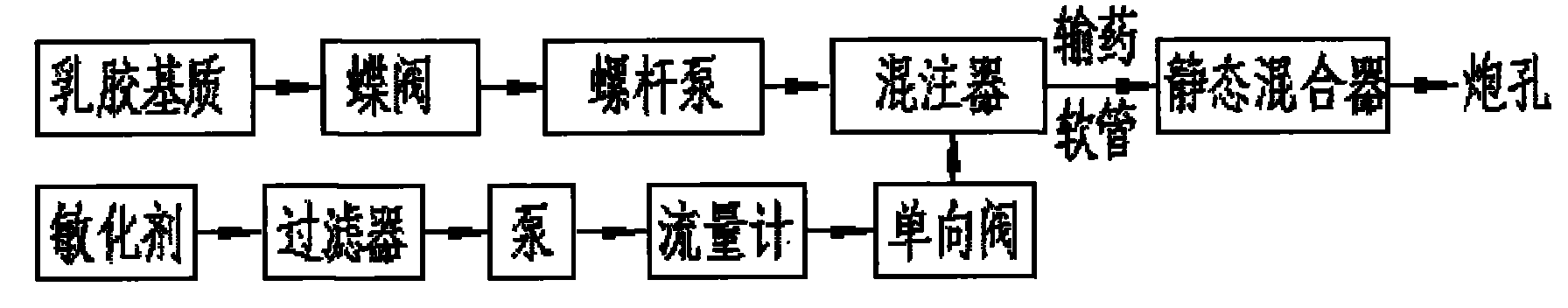

[0019] like figure 1 , 2 Shown, a kind of downhole on-site mixed emulsified explosive vehicle comprises: automobile chassis 1, secondary vehicle frame 2 is installed in the front portion of described automobile chassis 1, and lifting platform 20 is installed in the rear portion of described automobile chassis 1, so The secondary vehicle frame 2 is equipped with an outer box assembly 3, and the outer box assembly 3 is equipped with a storage and delivery device containing a sensitizer, a latex matrix storage and delivery device, a water storage and delivery device, and a material Conveying and mixing devices as well as power boxes and electric control boxes.

[0020] The sensitizer box 5, the filter 26, the sensitizer motor 25, the sensitizer pump 24, the electric remote transmission flow transmitter 23, and the one-way valve 17 store and transport the sensitizer, and the sensitizer box 5 is located at the front of the outer box assembly 3, and the filter 26, sensitizer motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com