Vacuum self-adsorptive heat insulation and noise reduction reinforced plastic flat plate

A reinforced plastic, self-adsorption technology, applied in the direction of sound insulation, sound insulation doors/windows, noise absorption devices, etc., can solve the problems of cumbersome process, high cost and complex structure of old doors and windows, and achieve significant economic and social benefits, reduce The effect of low production and maintenance costs and raw material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

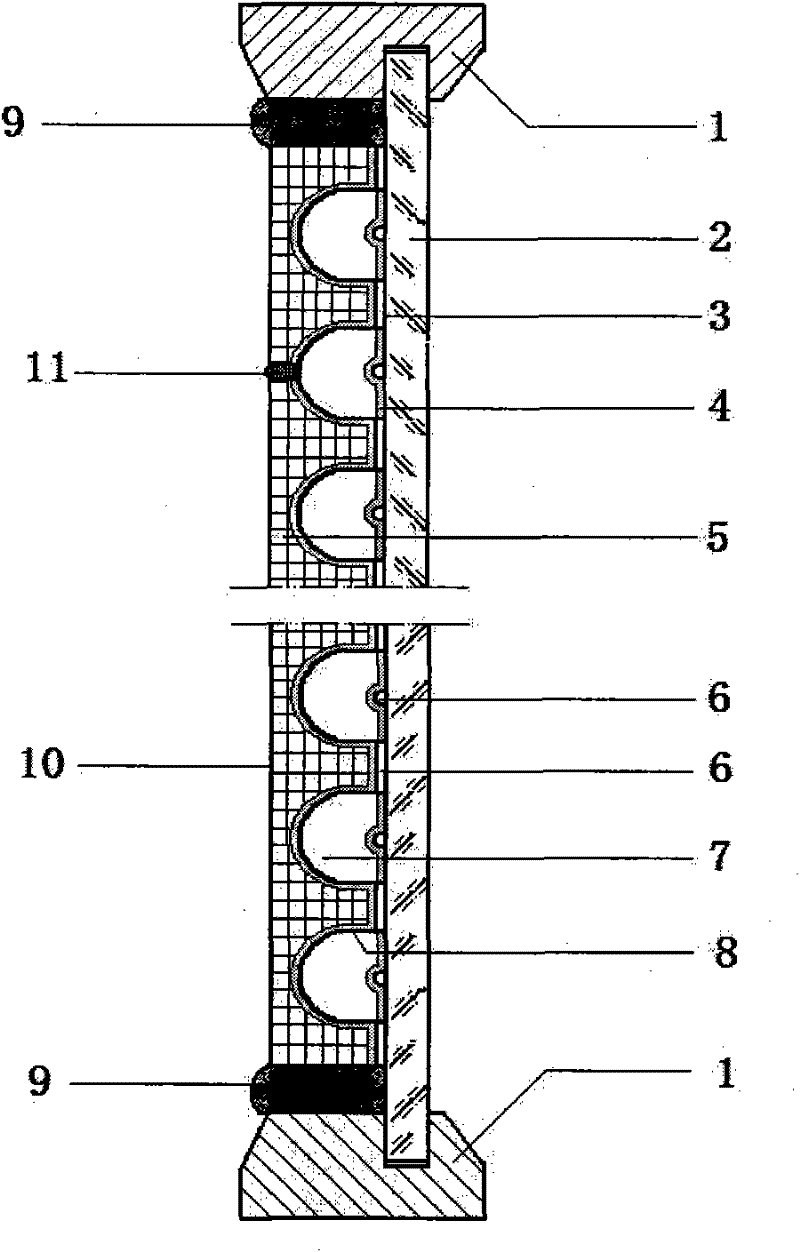

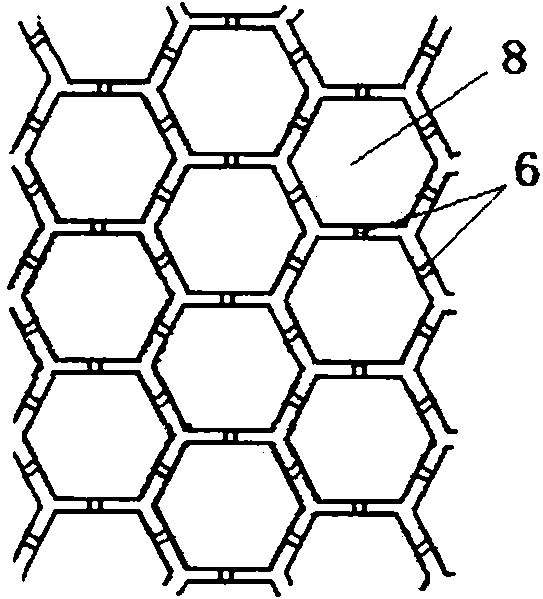

[0011] in the attached figure 1 Among them, a piece of flat glass (2) is embedded in the window frame (1), one side of which is covered with the main body of the present invention made of transparent reinforced plastic substrate (5)---a plastic flat plate with uniform thickness, the The reinforced plastic substrate is made of polytetrafluoroethylene (PTFE), or flexible polyvinyl chloride (PVC) to reduce costs. Its thickness is between 8-25mm, and one of the surfaces of the plastic plate is a flat and smooth plane ( 10), the other surface is made with many regularly arranged blind holes, attached figure 1 The surface is covered on the inner surface of the window glass (2), and the top part (7) of the blind hole is a concave hemispherical surface, attached figure 1 Show that the bottom part (8) of the blind hole is a circular cylinder, they are connected smoothly with the concave hemispherical surface of the above-mentioned blind hole top part (7), and there is a small groove (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com