Fully automatic tape pasting mechanism

A fully automatic, adhesive tape technology, which is applied in the direction of electrolyte battery manufacturing, sustainable manufacturing/processing, and delivery of objects, etc. It can solve the problems of plastic deformation of the tape, complicated operation, and difficult adjustment of the glue feeding position, so as to achieve convenient operation and prevent plastic deformation. , not easy to stretch relative to external force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

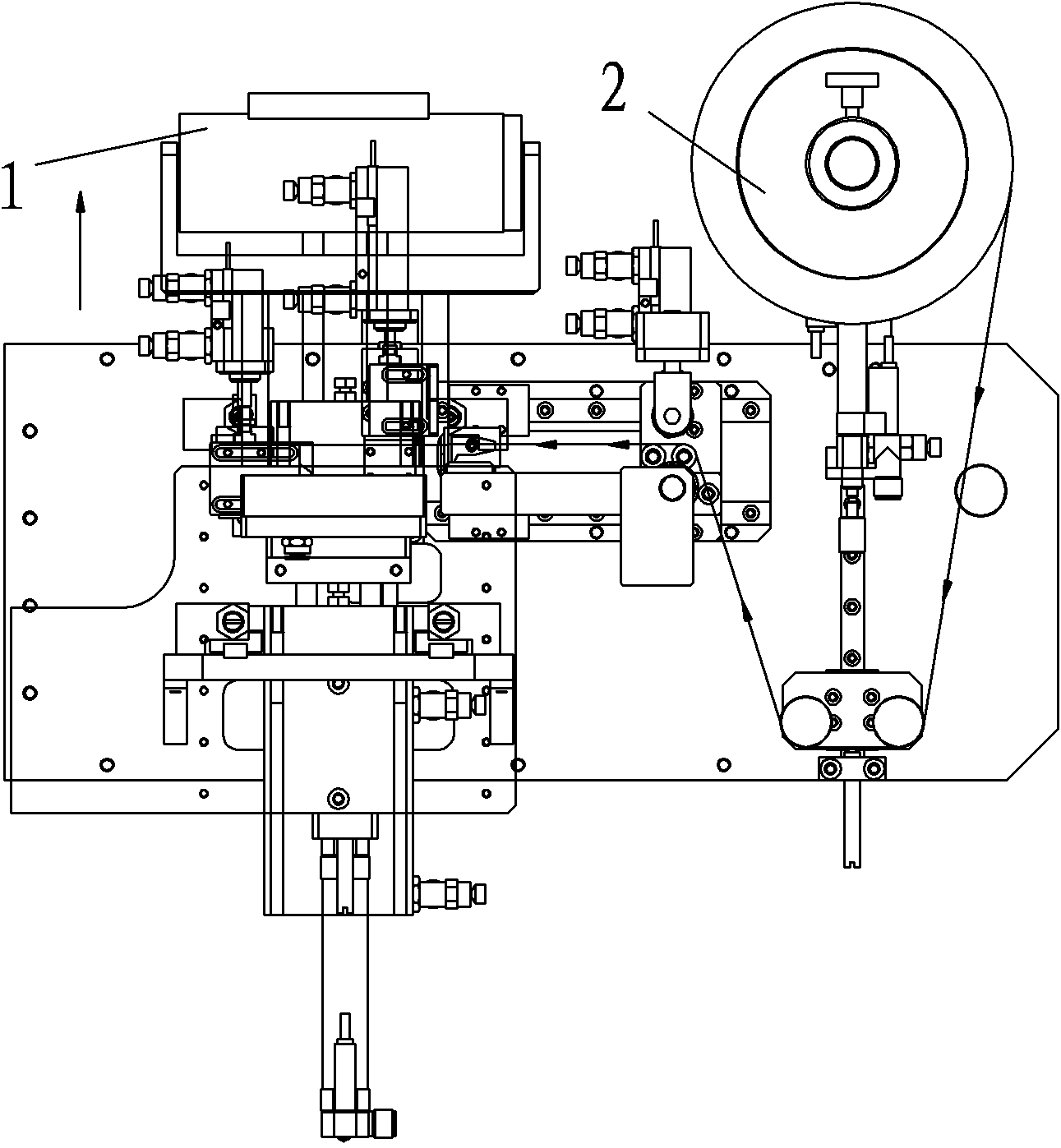

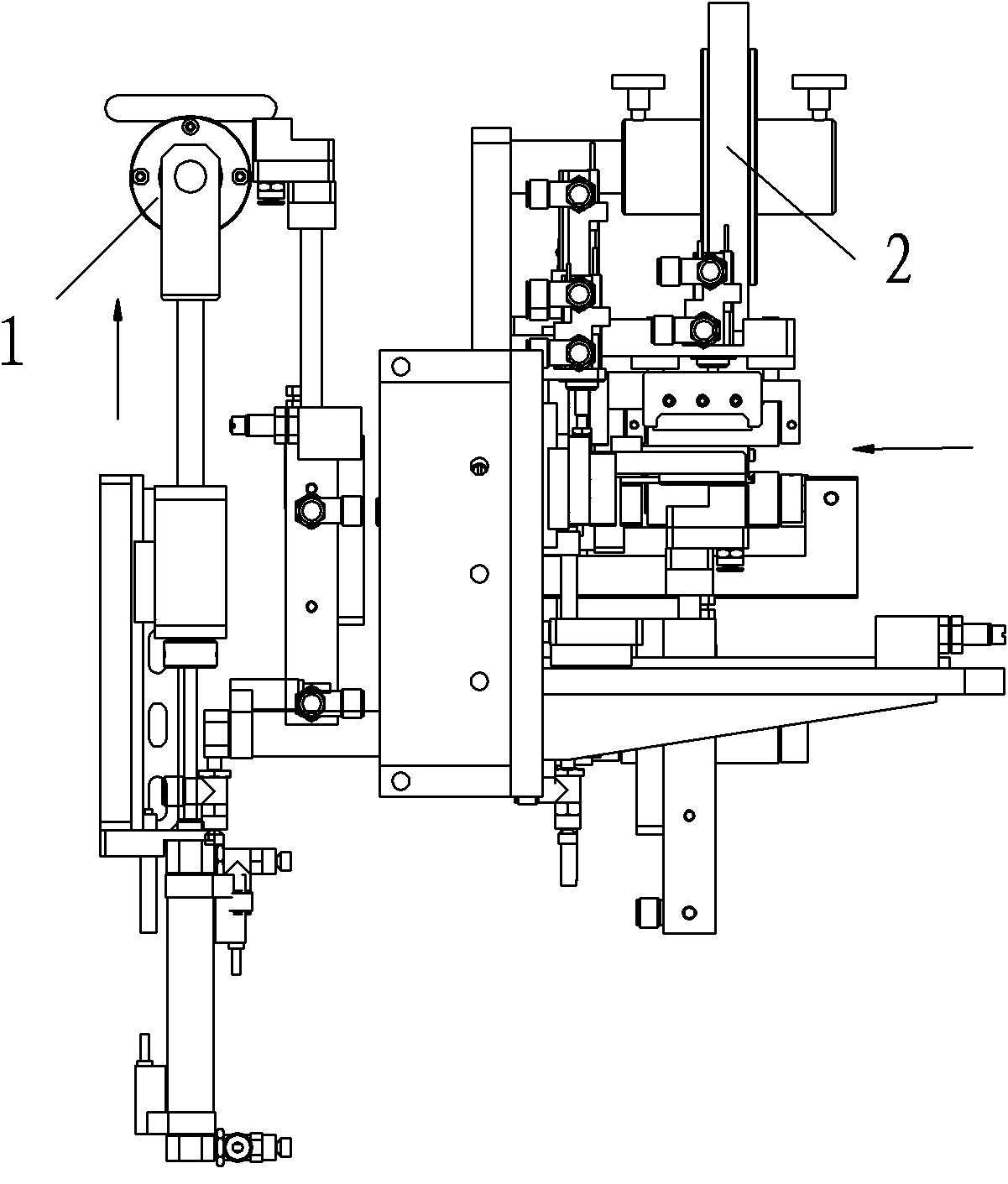

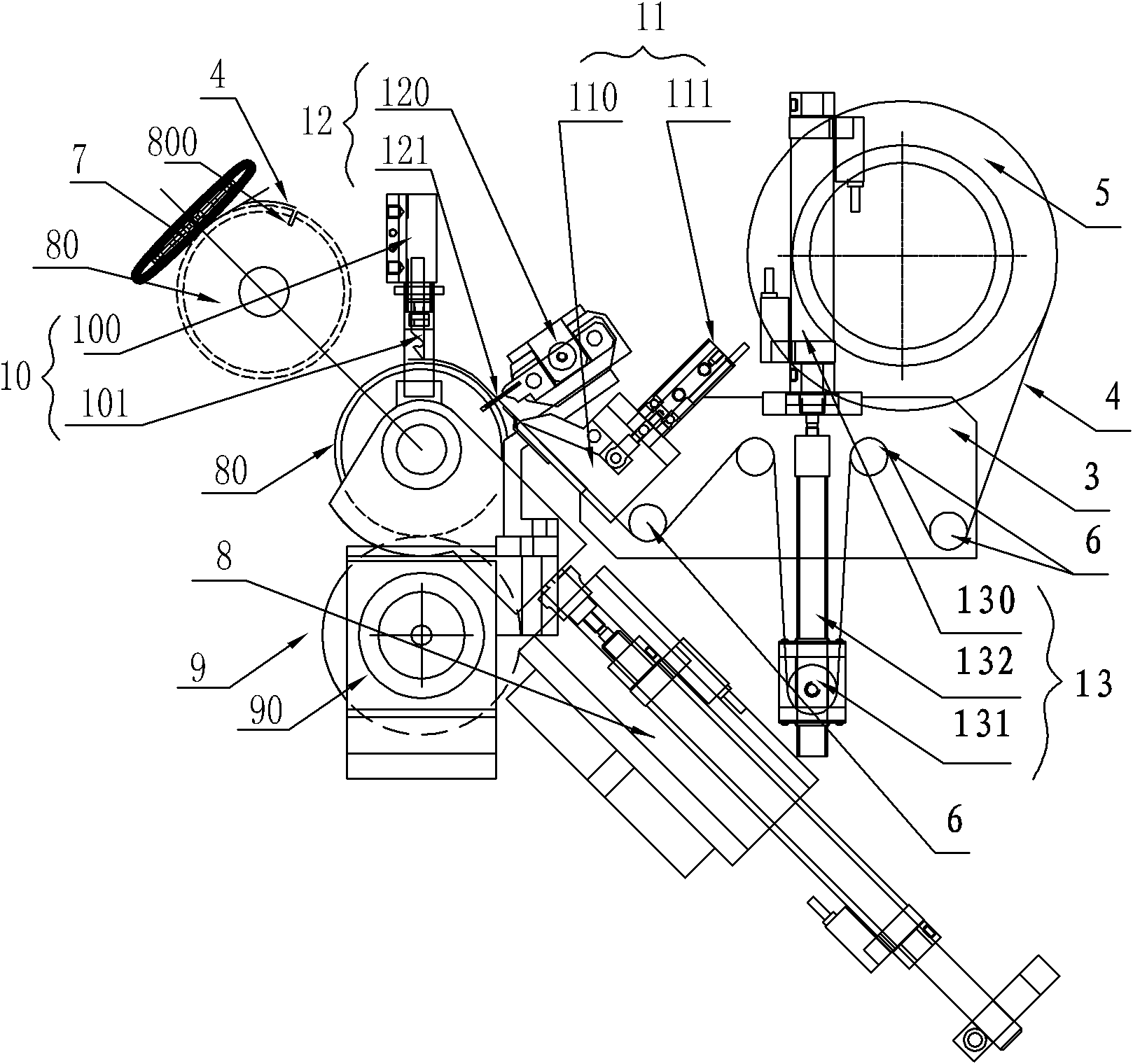

[0017] Such as image 3 As shown, the present embodiment provides a fully automatic sticking mechanism for adhesive tape, which is applied to lithium-ion battery cell production equipment. The production equipment includes a frame 3; The tape roller 5 of the tape 4 can be rotated and released; during the tape transfer process, there are a plurality of conveyor tape rollers 6 installed on the frame; on the lower right side of the battery cell 7 to be glued, there is a tape for winding And convey the adhesive tape 4 after cutting to the gluing wheel 80 of the gluing pressing position of the battery cell 7 to be gluing; drive the first driving device 8 of the gluing wheel 80 for linear motion, The wheel 80 is driven by the first driving device 8 and moves obliquely along a straight line at a certain angle with the horizontal direction, and the angle and direction of the adhesive tape can be adjusted. The adhesive wheel 80 can be applied to different types of batteries to be adhes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com