High-speed yaw scanning control device for testing quality of electron beam current

A technology of electron beam current and yaw scanning, applied in electromagnetic measurement devices, electrical devices, measurement devices, etc., can solve the problems of large error in detection results, inability to change, single scanning waveform, etc., to achieve accurate timing relationship correspondence, improve The effect of anti-interference ability and high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

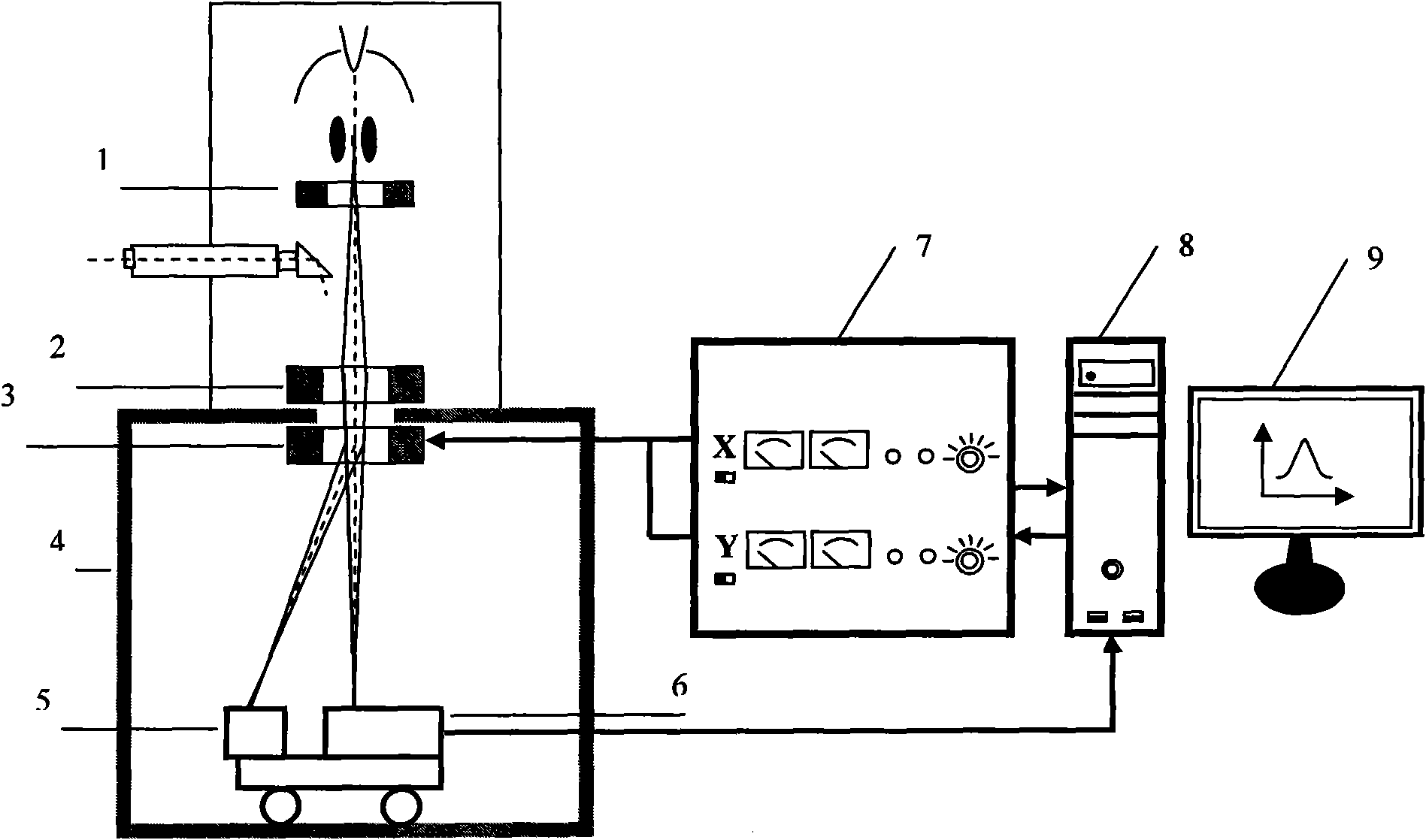

[0021] The high-speed deflection scanning control device of the present invention is to test the quality of the electron beam, including the diameter of the beam spot and the distribution of the beam power density, and is located in the electron beam quality testing system. The electron beam quality testing system includes an electron beam welding machine , industrial computer 8 and industrial computer display 9, the electron beam welding machine comprises focusing coil 1, yaw coil 2 and vacuum working room 4, and during testing, electromagnetic deflection coil 3, energy absorbing device (copper, Metal such as stainless steel) 5, sensor 6, focusing coil 1, yaw coil 2, electromagnetic deflection coil 3 are coaxial, the upper surface of electromagnetic deflection coil 3 is close to the top of vacuum studio 4, electromagnetic deflection coil 3 and deflection scanning control device 7, the industrial computer 8 is connected to the deflection scanning control device 7 through a DB-9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com