Stereo buried cylindrical concrete coffin for deep-well tomb hole and preparation method thereof

A concrete and cylindrical technology, applied in the field of concrete coffins and their preparation, can solve the problems of tombs destroying the ecological environment, destroying the environmental landscape, occupying land resources, etc., and achieving the effects of good corrosion resistance, convenient use and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

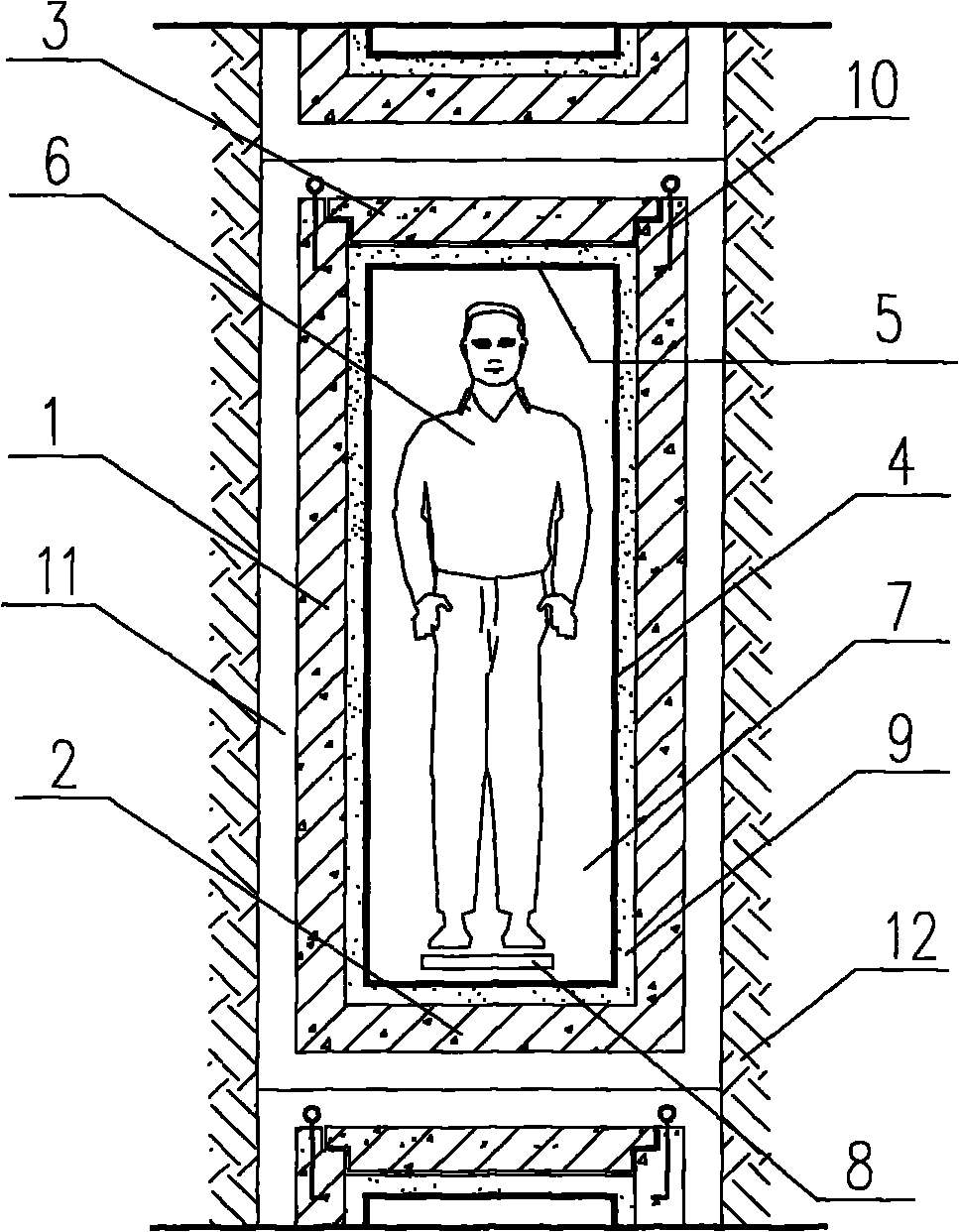

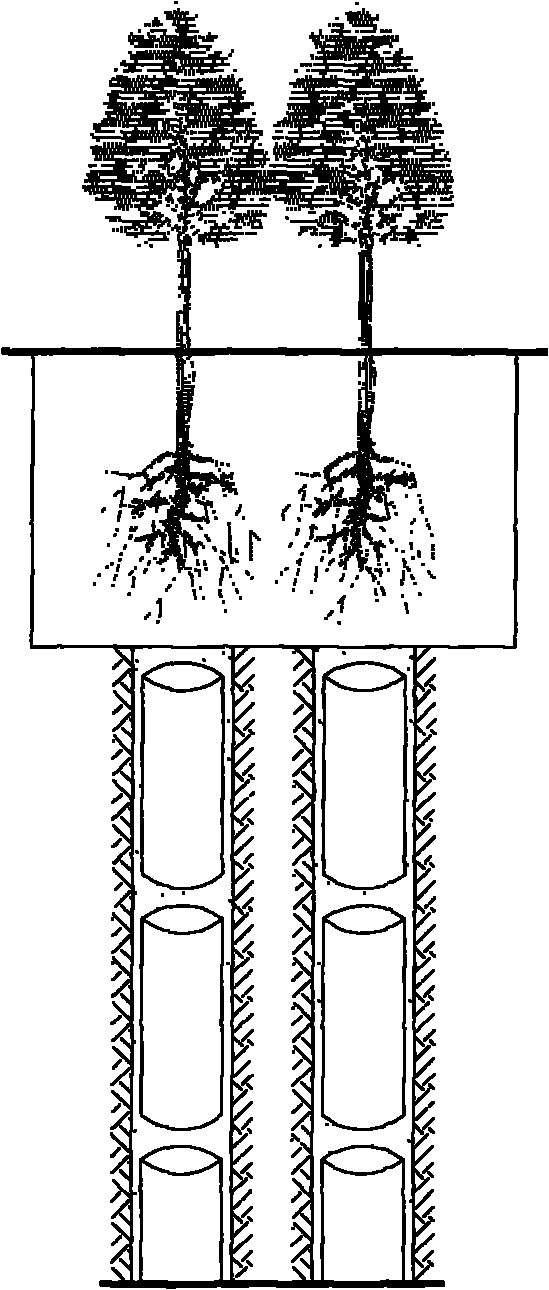

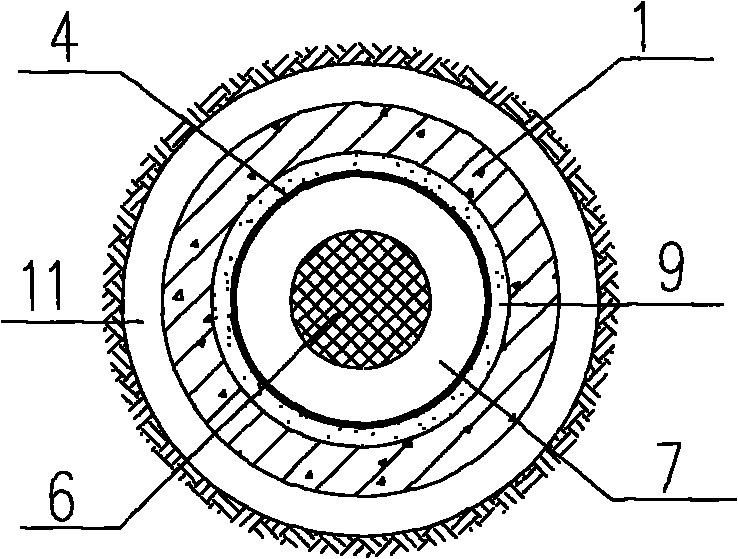

[0027] A cylindrical concrete coffin for three-dimensional burial in a deep well-type tomb hole. The outer structure is composed of a tubular concrete coffin body 1, a disc-shaped concrete coffin bottom 2, a disc-shaped concrete coffin cover 3 and a hook and rope assembly 10, wherein , a round tubular concrete coffin body 1 and a disc-shaped concrete coffin bottom 2 are integrally cast and formed; an inner plastic barrel body 4 covered with a plastic barrel cover 5 for storing remains 6 is provided in the outer layer structure, and the inner layer plastic barrel body 4 is provided with an anti-corrosion filler 7, and the bottom of the inner plastic barrel 4 is placed with a data bag 8; the gap between the outer structure and the inner plastic barrel 4 is filled with a concrete grouting material filling layer 9.

Embodiment 2

[0029] The preparation method of the three-dimensional burial cylindrical concrete coffin of the deep well type tomb hole is as follows:

[0030] Step 1. Prepare and mix concrete, weld the steel skeleton, adopt concrete pipe making technology, and make a round tubular concrete coffin body 1 and a disc-shaped concrete coffin bottom 2 in one piece, forming a pot-shaped outer structure of the concrete coffin, and making a disc-shaped concrete coffin Cover 3, pre-embedded hook sling assembly 10;

[0031] Step 2 Carry out embalming treatment on the remains 6, put the remains 6 into a body bag, put them into the inner plastic barrel body 4, place the information bag 8 at the bottom of the inner layer plastic barrel body 4, and fill the inner layer plastic barrel body with the antiseptic filler 7 4 and the gap between the remains 6, cover the plastic bucket cover 5 that smears the adhesive, evacuate the air in the inner plastic bucket body 4, and inject the sealant;

[0032] Step 3:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com