Waste heat recovery device

A waste heat recovery device and superheater technology, which is applied in waste heat treatment, lighting and heating equipment, furnaces, etc., can solve the problems of over-temperature tube explosion, tube explosion, and allowable stress reduction, so as to reduce the fluctuation range of working conditions and reduce The effect of ash on the heated area, preventing drift and eddy currents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, wherein the positional relationship of "up" and "down" described in this description corresponds to the positional relationship between up and down shown in the drawings.

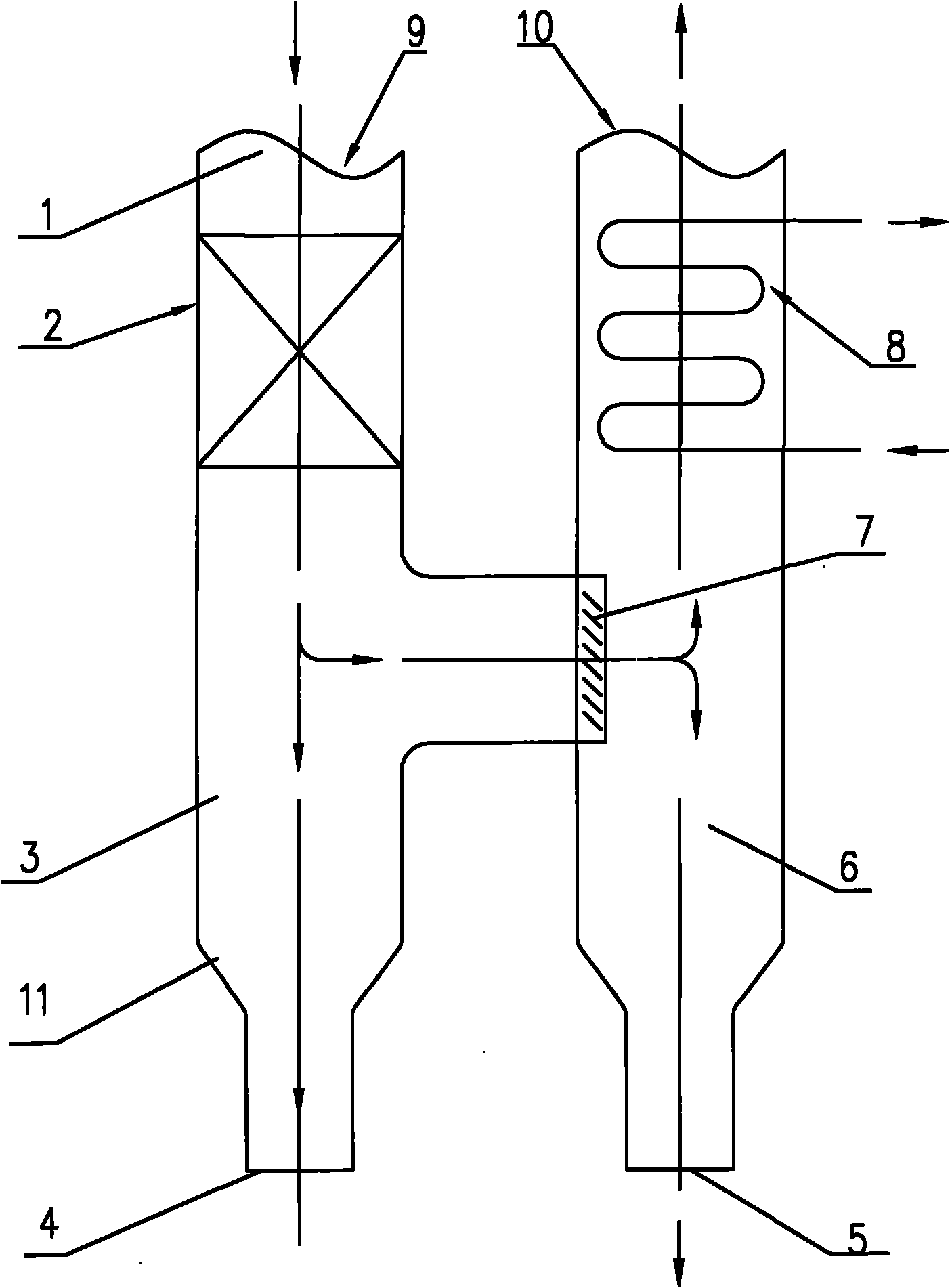

[0015] A waste heat recovery device, which includes a primary ash settling chamber 3 communicated with the flue 1, a secondary ash settling chamber 6 communicated with the primary ash settling chamber 3, and arranged in the primary ash settling chamber 6 The pre-evaporator 2 in the settling chamber 3 and the superheater 8 arranged in the secondary ash settling chamber 6 . The first-level ash settling chamber 3 and the second-level ash settling chamber 6 are arranged side by side in an "H" shape, and the upper part of the first-level ash settling chamber 3 is provided with a flue gas inlet 9, and the first-level ash settling chamber 6 is arranged side by side. There is a primary ash out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com