Method and device for preparing synthesis gas by coal particle/oxygen carrier chemical chain

An oxygen carrier and synthesis gas technology, which is used in the gasification of granular/powdered fuel, the manufacture of combustible gas, and energy input.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

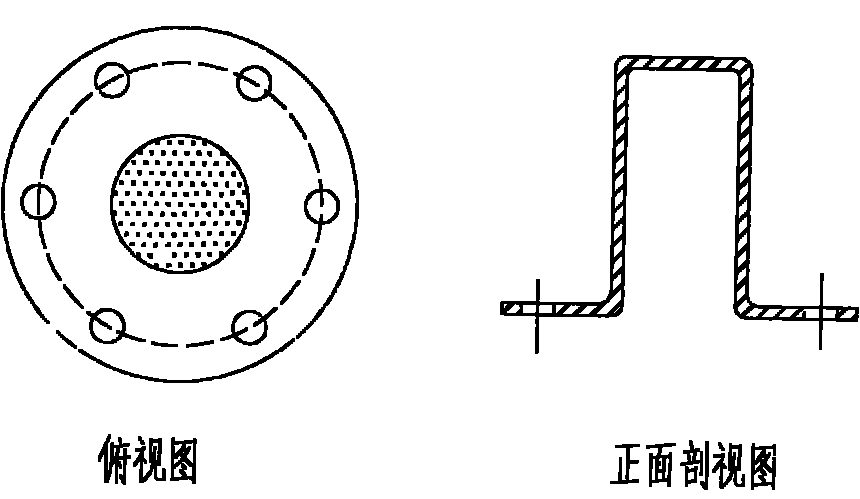

[0026]The basic principle of this embodiment is to use double chemical chains to prepare synthesis gas. The oxygen carrier undergoes a reduction reaction with coal particles in the oxygen carrier gasifier, and then undergoes an oxidation reaction with air in the air reactor. The circulation of the oxygen carrier Syngas produced by reaction; purification of syngas and CO 2 The capture utilizes CaCO 3 / CaO chemical chain completed; composite CaSO 4 / CaCO 3 CaCO 3 / CaO chemical chain purification and CO capture 2 Coupling to the oxygen carrier chemical chain synthesis gas production process, the syngas production and synthesis gas purification and CO 2 The two chemical chain processes are carried out at the same time; the process for preparing syngas is as follows: first, the coal and the oxygen carrier are reacted in the oxygen carrier gasifier, and the CO-free gas is obtained through the secondary separation of the cyclone separator. 2 The synthesis gas; then the solids ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com