Tobacco stalk straightening device

A technology of tobacco stems and vibrating grooves, which is applied in the fields of tobacco, tobacco processing, transportation and packaging, etc., and can solve the problem of unstable quality of cigarettes, uneven blending of shredded leaves and shredded stems, and placement of tobacco stems. Inconsistent direction and other problems, to achieve high strength, simple structure, good cutting angle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

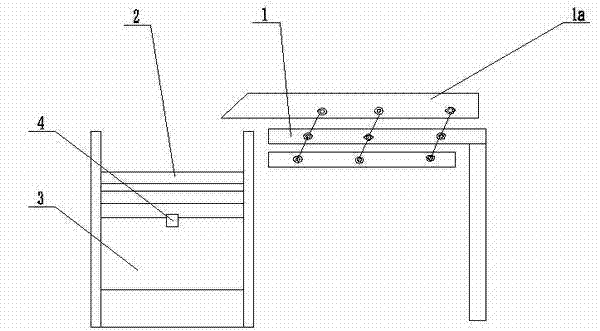

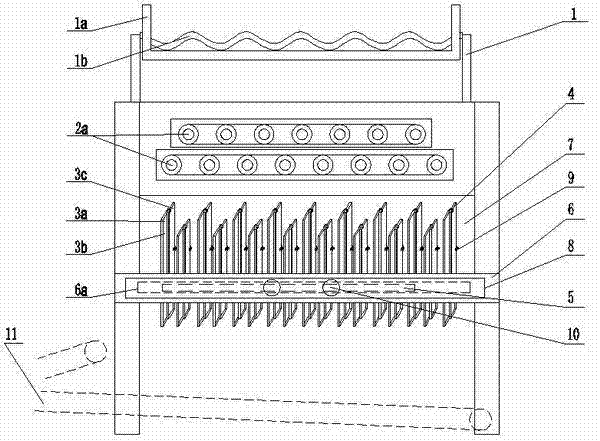

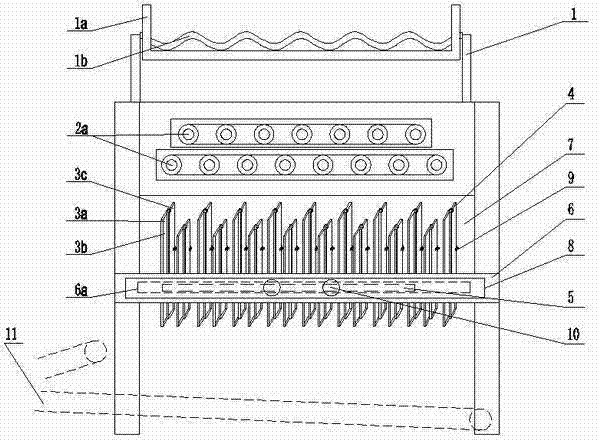

[0016] Such as figure 1 , 2 As shown, a device for straightening tobacco stems of the present invention consists of three parts: vibrating groove 1, wheel set 2, and baffle plate set 3. The vibration tank 1 is composed of a tank body 1a, a motor, a main shaft, a balance part, an eccentric mechanism and a connecting rod. The vibrating trough is a common connecting rod vibration mechanism in the tobacco industry. The bottom of the trough 1a is usually a flat plate. The motor drives the main shaft to rotate through the belt drive. When the main shaft rotates, the eccentric mechanism installed on the main shaft drives the balance part and the trough. Do reciprocating motion. Due to the vibration of the tank body 1a, the material moves forward in the tank body 1a along the direction of the vibration tank to achieve the function of conveying materials. During i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com