Heat radiation system

A heat dissipation system and hot air duct technology, applied in the mechanical field, can solve problems such as large temperature gradients that affect the heat dissipation of network equipment in the cabinet, and achieve the effect of improving cooling efficiency and good heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

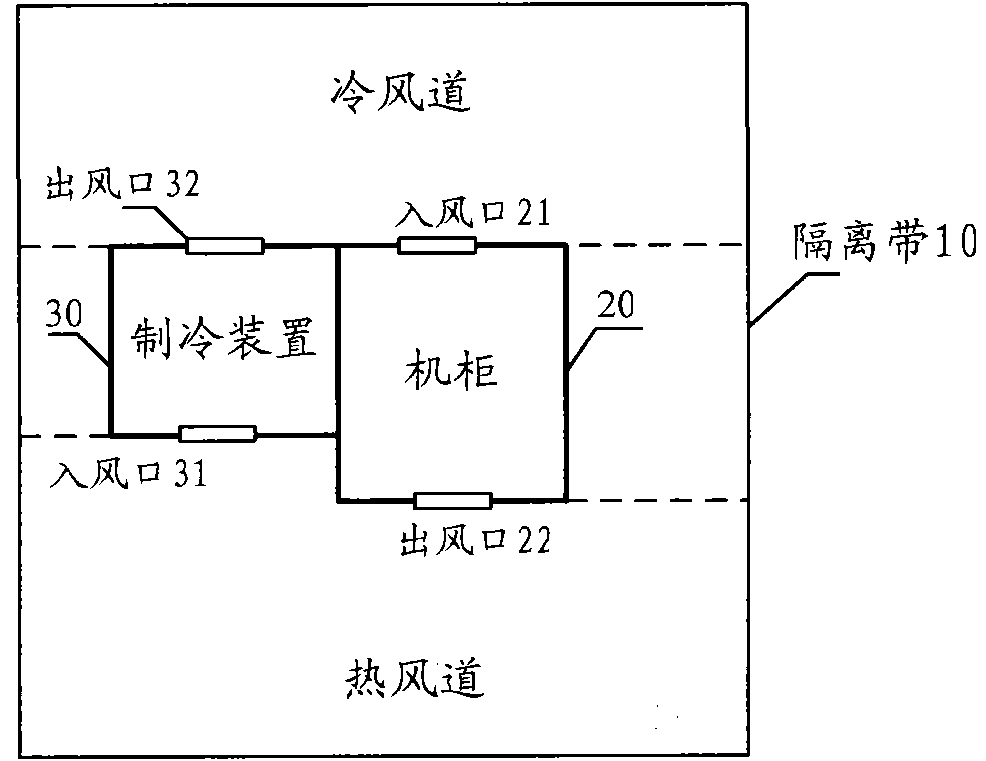

[0021] An embodiment of the present invention provides a cooling system, image 3 A top view of the heat dissipation system is shown, which includes: an isolation strip 10 for separating the cold air passage from the hot air passage; the isolation strip includes: a cabinet 20 and a refrigeration device 30,

[0022] Wherein, the cooling device 30 has an air outlet 32 on the side facing the cold air passage, and the cabinet 20 has an air inlet 21 on the side facing the cold air passage; The air inlet 21 enters; the side of the refrigeration device 30 facing the hot air passage has an air inlet 31, and the side of the cabinet 20 facing the hot air passage has an air outlet 22; the hot air discharged from the air outlet 22 of the cabinet 20 passes through the hot air passage Enter from the air inlet 31 of the refrigeration device 30 .

[0023] In the heat dissipation system in the embodiment of the present invention, there is an isolation zone for separating the cold air duct a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com