Yoke structure of stepping motor

A technology of stepping motor and yoke structure, applied in the direction of magnetic circuit shape/style/structure, electrical components, electromechanical devices, etc., can solve problems such as cost reduction, achieve cost reduction, reduce maintenance and management costs, and stabilize quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

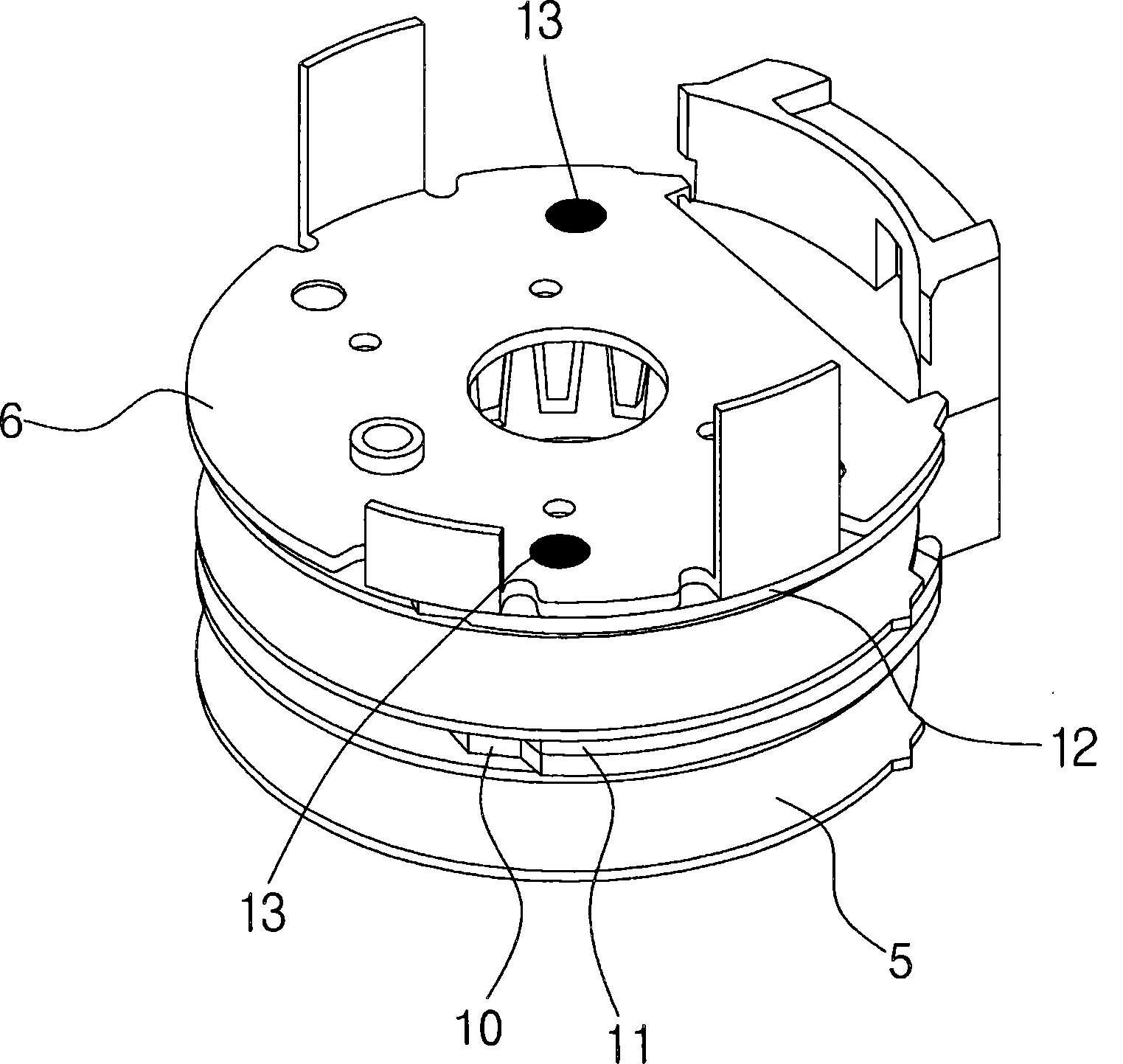

[0014] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

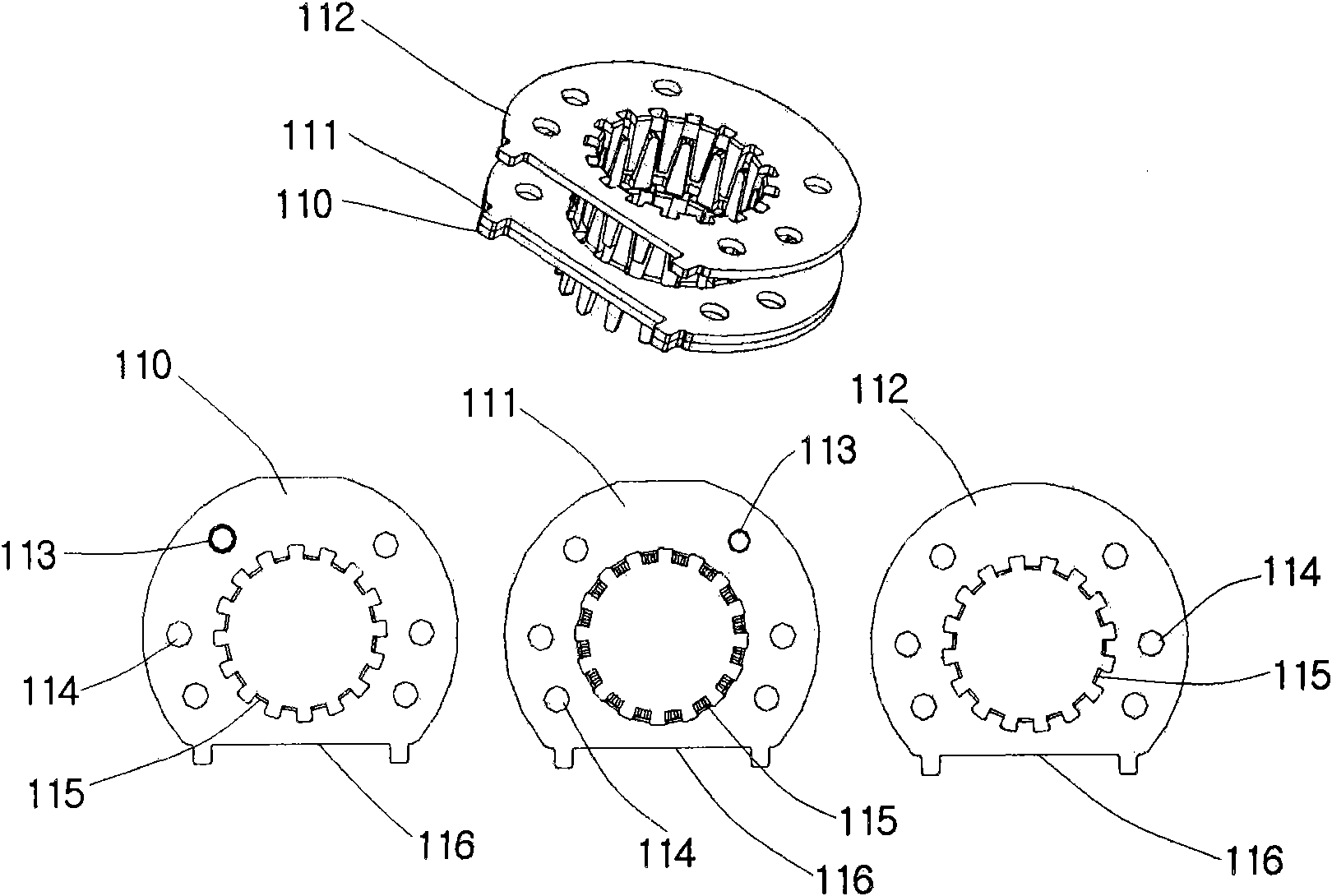

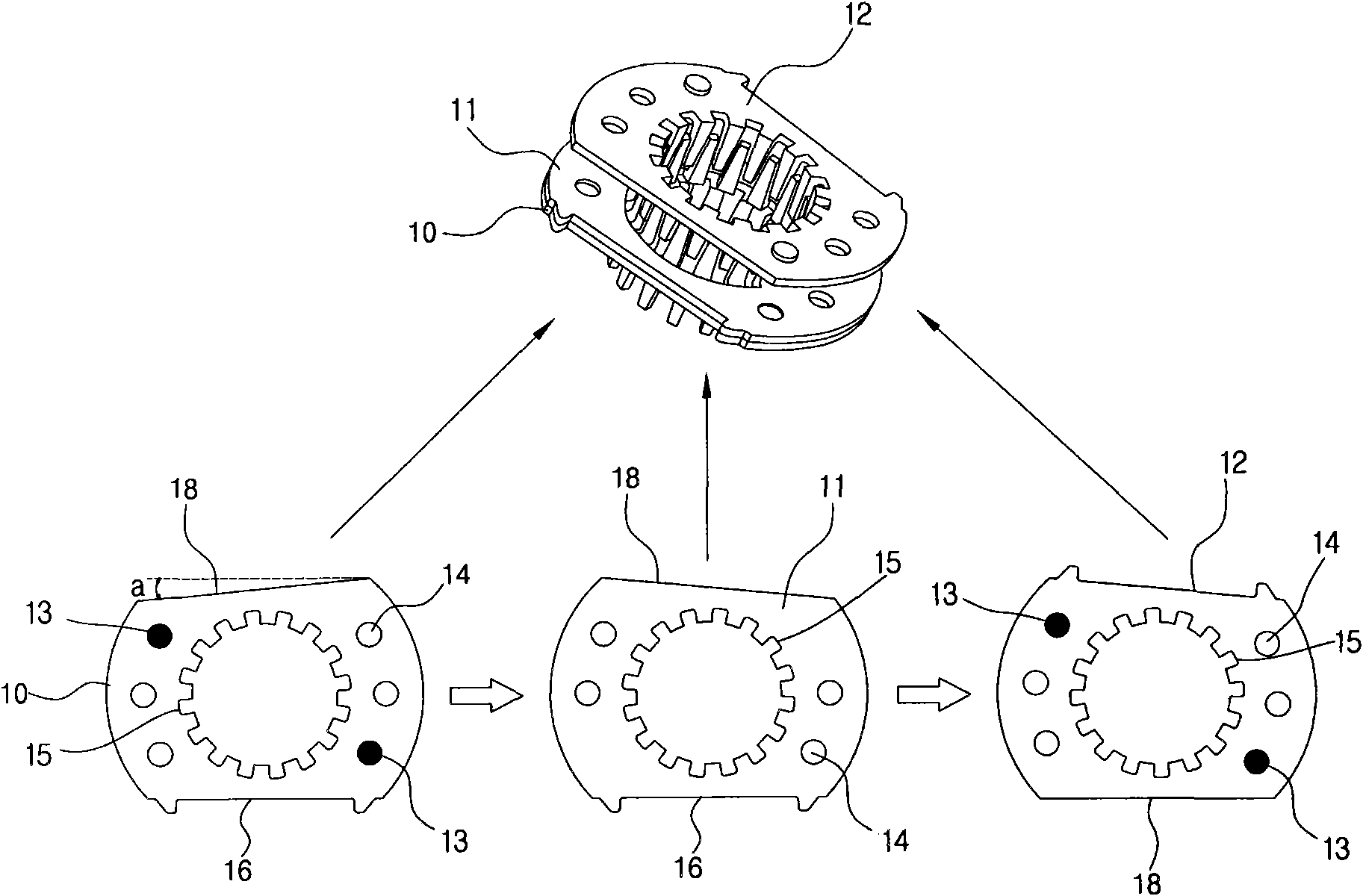

[0015] Such as figure 2 with image 3 As shown, the yoke 10, the yoke 11 and the yoke 12 are the same yoke, and the yoke 10, the yoke 11 and the yoke 12 respectively include: a lower cut-off part 16, an upper guide part 18 inclined at a°, a central gear tooth 15, and a The gear teeth 15 are spaced apart by a plurality of through holes 14 and protrusions 13 at a set distance. In the figure, two through holes 14 and one protruding portion 13 form a group, and two groups are provided on both sides, forming a symmetrical relationship. Since the yoke 11 is shown on the back side, the protrusion 13 cannot be seen.

[0016] The a° inclination angle of the upper guide portion 18 is the step angle of the motor. For example, when the motor rotates at a step angle of 7.5°, the tilt angle of a° is 7.5°, and when the motor rotates at a step angle of 15°, the tilt angle of a° is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com