Device for manufacturing copper indium gallium selenium (CIGS) thin-film solar cells

A technology of solar cells and copper indium gallium selenide, which is applied in the manufacture of circuits, electrical components, and final products, and can solve the problems of poor ability to form pn junctions and low quality of processed products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The manufacturing device for copper indium gallium selenium thin film solar cells will be further described in detail below with reference to the drawings and examples.

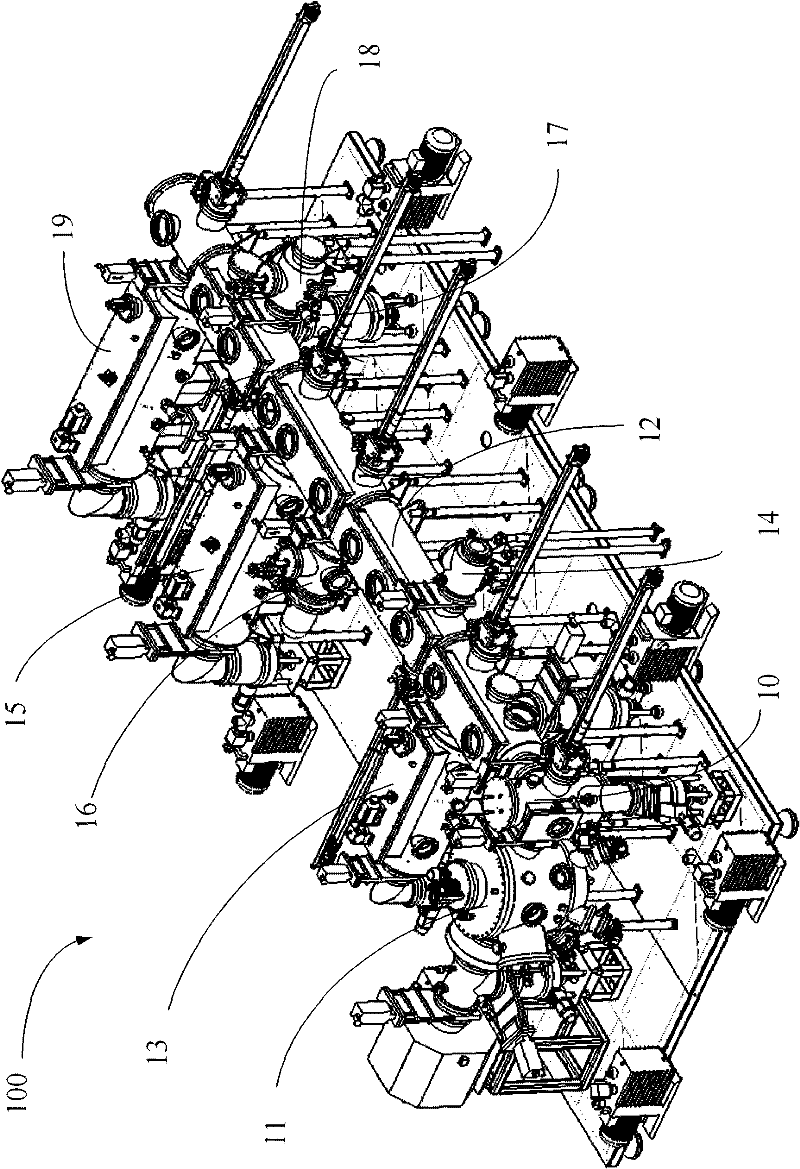

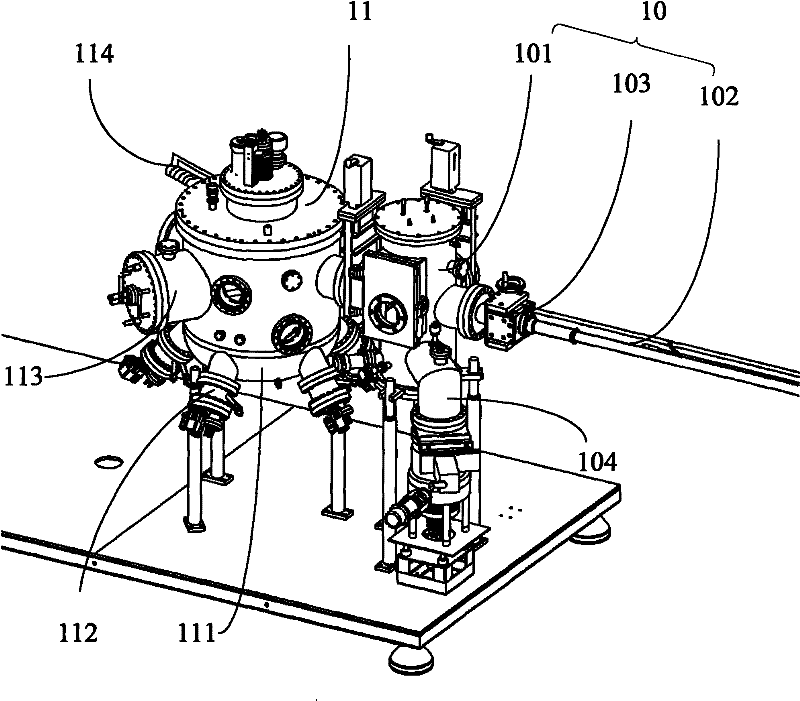

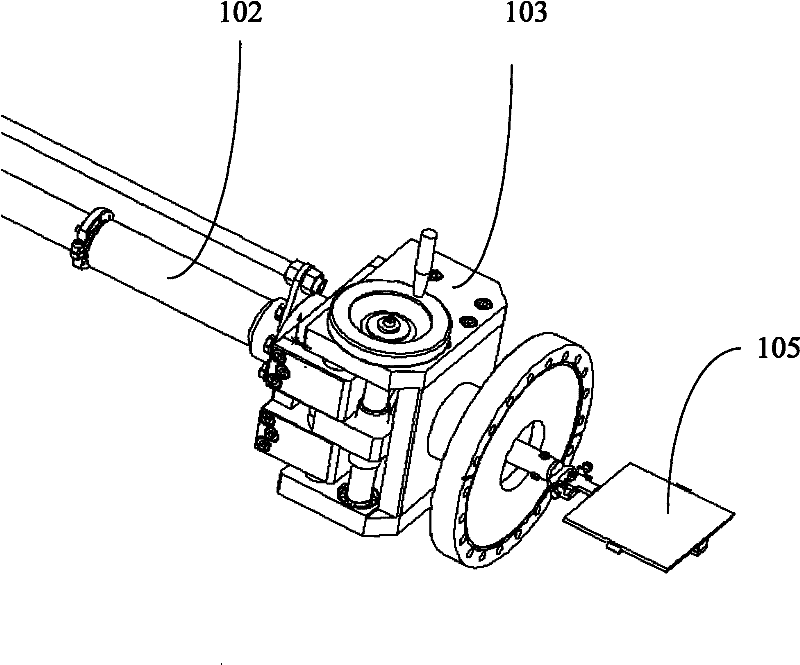

[0024] see figure 1 In one embodiment, the CIGS thin-film solar cell fabrication device 100 is composed of a plurality of interconnected fabrication chambers. These preparation chambers include a sampling chamber 10, a copper indium gallium selenium evaporation chamber 11 and a sample running chamber 12 connected in vacuum to the sampling chamber 10, a molybdenum sputtering chamber 13 connected in vacuum to the sample running chamber 12, a laser photolithography chamber 14, Copper Indium Gallium Sputtering Chamber 15 , Selenization Chamber 16 and Zinc Oxide Sputtering Chamber 19 . The CIGS thin film solar cell preparation device 100 also includes a transition chamber 18 connected to the sample operation chamber 12 and an electrochemical reaction chamber 17 connected to the transition chamber 18 and un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com