Manufacturing method of semiconductor device

A manufacturing method and semiconductor technology, which are applied in the fields of semiconductor/solid-state device manufacturing, electrical components, photolithography process exposure devices, etc., can solve problems such as formation of defects on the surface of wafers, and achieve the effect of reducing the probability of conductive impurity debris

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

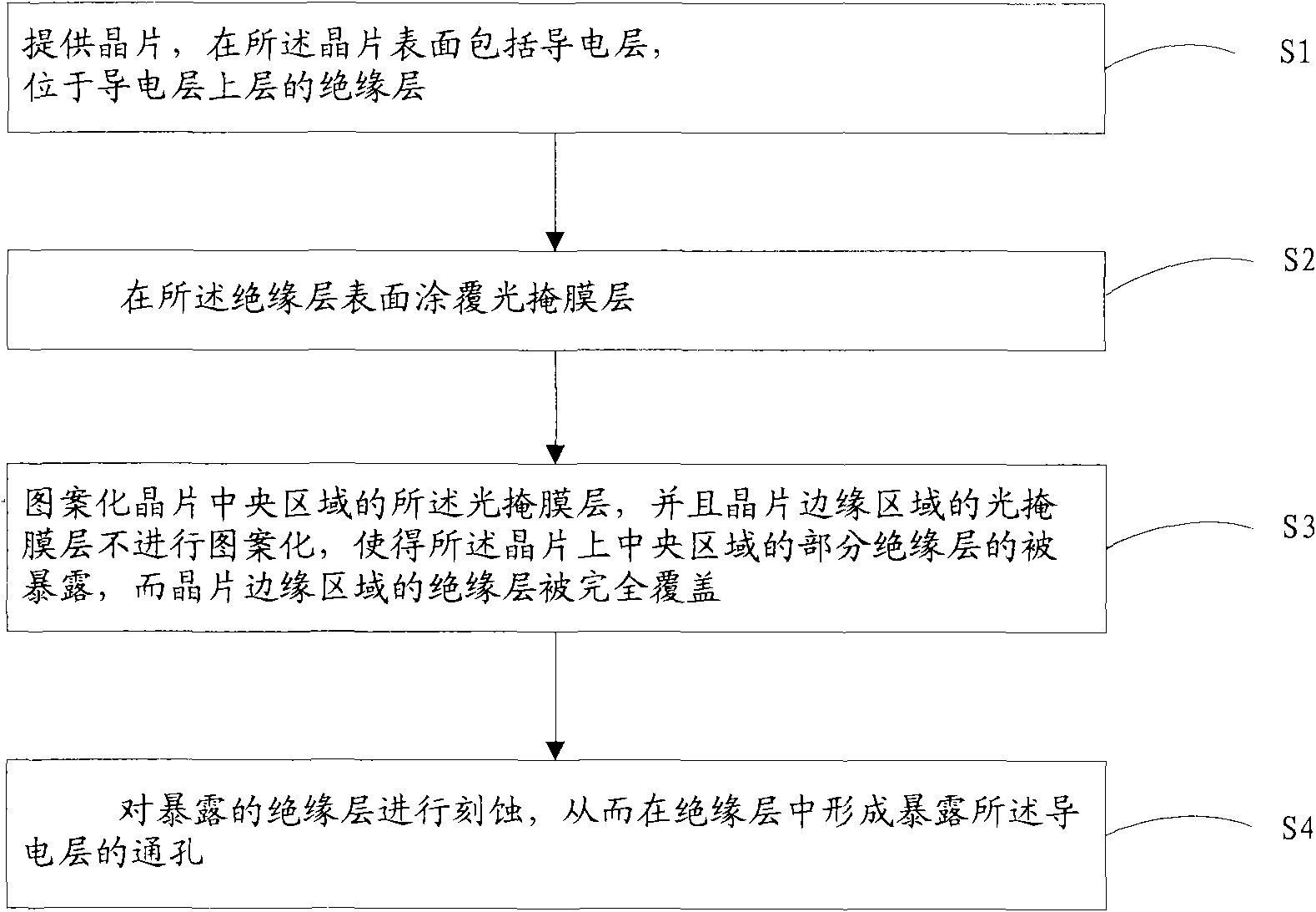

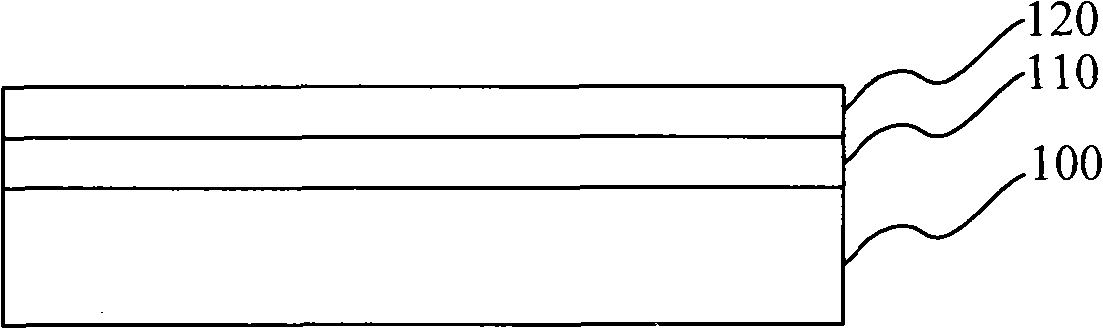

[0054] figure 2 It is a flowchart of an embodiment of the manufacturing method of the semiconductor device of the present invention. Figure 3 to Figure 8 It is a schematic diagram of an embodiment of the manufacturing method of the semiconductor device of the present invention. in, Figure 3 to Figure 5 and Figure 7 to Figure 8 is a cross-sectional diagram, Figure 6 It is a top view diagram.

[0055] refer to figure 2 , a method for manufacturing a semiconductor device, comprising the steps of:

[0056] S1: providing a wafer, comprising a conductive layer on the surface of the wafer, and an insulating layer located on the conductive layer.

[0057] Specifically, refer to image 3 , the wafer 100 includes a conductive layer 110, which may be a metal connection of different wiring layers, and the conductive layer 110 may also be a source, a drain or a gate of a MOS device. In another embodiment, there may also be a semiconductor device layer between the conductive l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com