Failure detection method and device

A detection method and detection device technology, applied in the direction of measuring devices, semiconductor/solid-state device testing/measurement, electrical measurement, etc., can solve the problems that cannot meet the needs of small-scale failure analysis, low sensitivity and positioning accuracy of OBIRCH technology, and avoid thermal effects , to avoid size restrictions, to avoid the effect of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

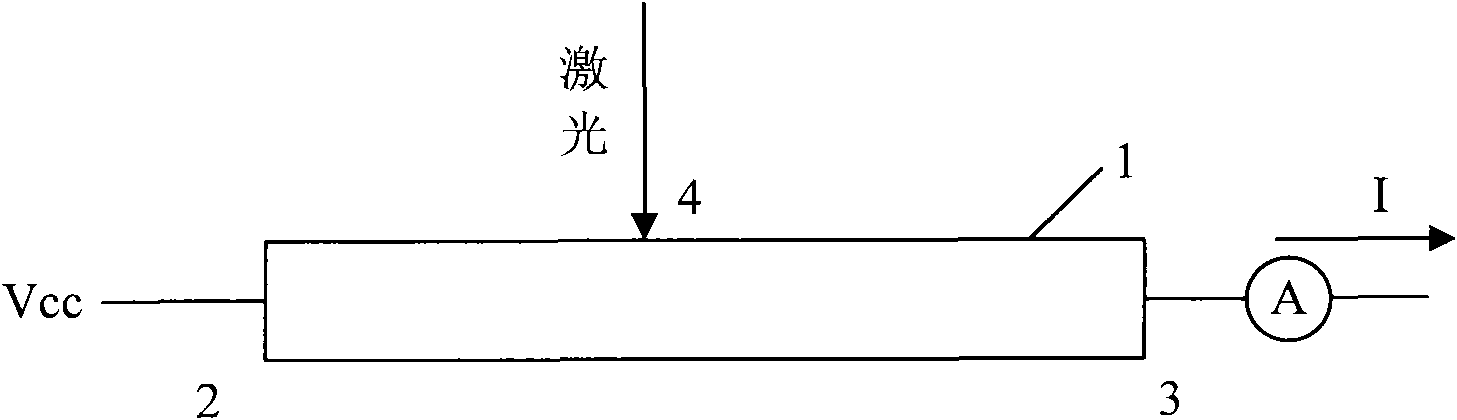

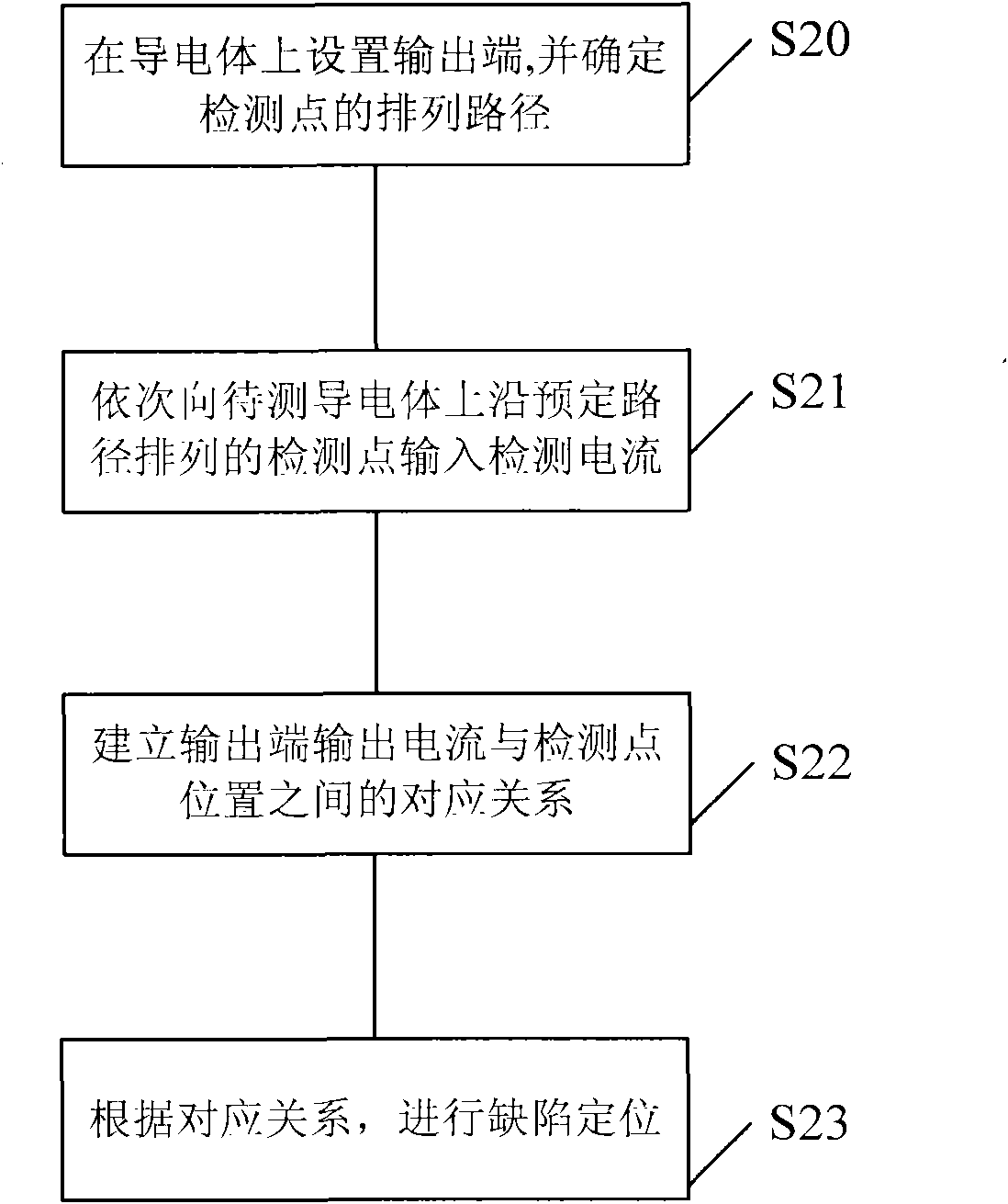

[0034] According to the law of conservation of charge, the sum of the output currents of the device is equal to the sum of the input currents. Therefore, if several output terminals with equal potential potentials are set on the conductor (that is, the potential potential of each output terminal is the same), and when the detection current is input on the conductor, all The sum of the currents at the output terminals is a constant value. Since the current always tends to the path with the least impedance, the current at each output terminal depends on the resistance between the output terminal and the detection point. When the position of the detection point changes, the current of each output terminal will also change accordingly. This change should be corresponding and unique, that is, when the same detection current is input at a fixed detection point, the output current of each output terminal should be Fixed, the output current of each output end forms a corresponding rel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com