Testing device for CVT (Constant-Voltage Transformer) valve body performance testing

A test device and performance technology, which is applied in the direction of measuring device, mechanical component test, machine/structural component test, etc., can solve the problems of unfavorable product development, long test cycle, high test cost, etc., to reduce test cost and simple structure , the effect of shortening the test cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

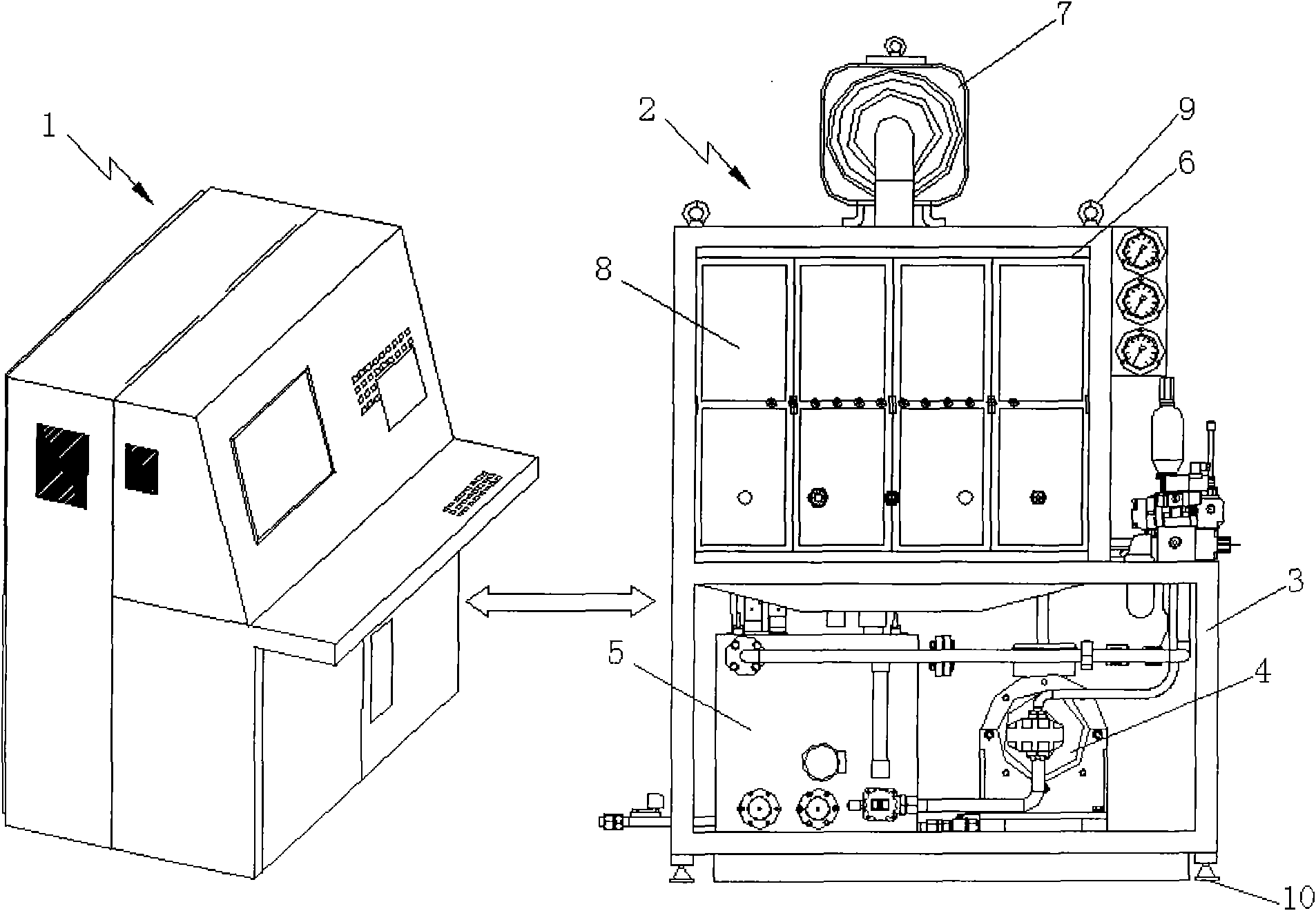

[0025] Such as figure 1 As shown, the present invention is composed of a control machine 1 and a testing machine 2 connected. The control machine 1 includes an operation console and its internal control circuit. The testing machine 2 includes a frame assembly 3, a hydraulic system 4, a hydraulic oil tank 5, and a test chamber 6. The hydraulic system 4 is connected to the hydraulic oil tank 5 and is located at the bottom of the frame assembly 3. The test chamber 6 is located at the top of the frame assembly 3. The frame An oil mist collector 7 is installed on the top of the assembly 1. This is because during the high-temperature test, high-temperature oil will be generated in the experimental cabin, which is unfavorable to the observation of the test conditions in the experimental cabin, and the oil will condense in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com