Detection device for oil pipe coupling

A detection device and tubing technology, applied in measurement, wellbore/well components, earthwork drilling and production, etc., can solve the problems of large detection error, low reliability, complex structure, etc., and achieve convenient operation, reasonable structure, and accurate detection results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

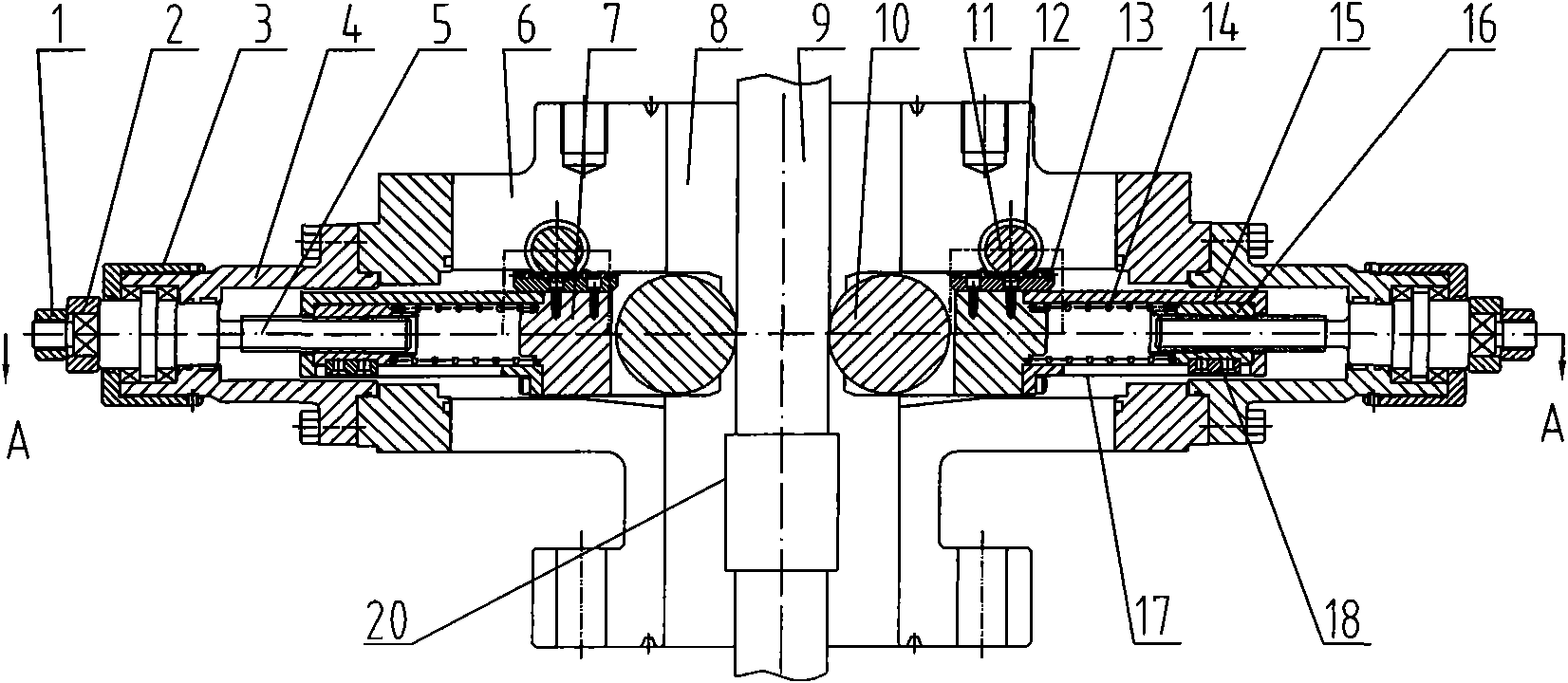

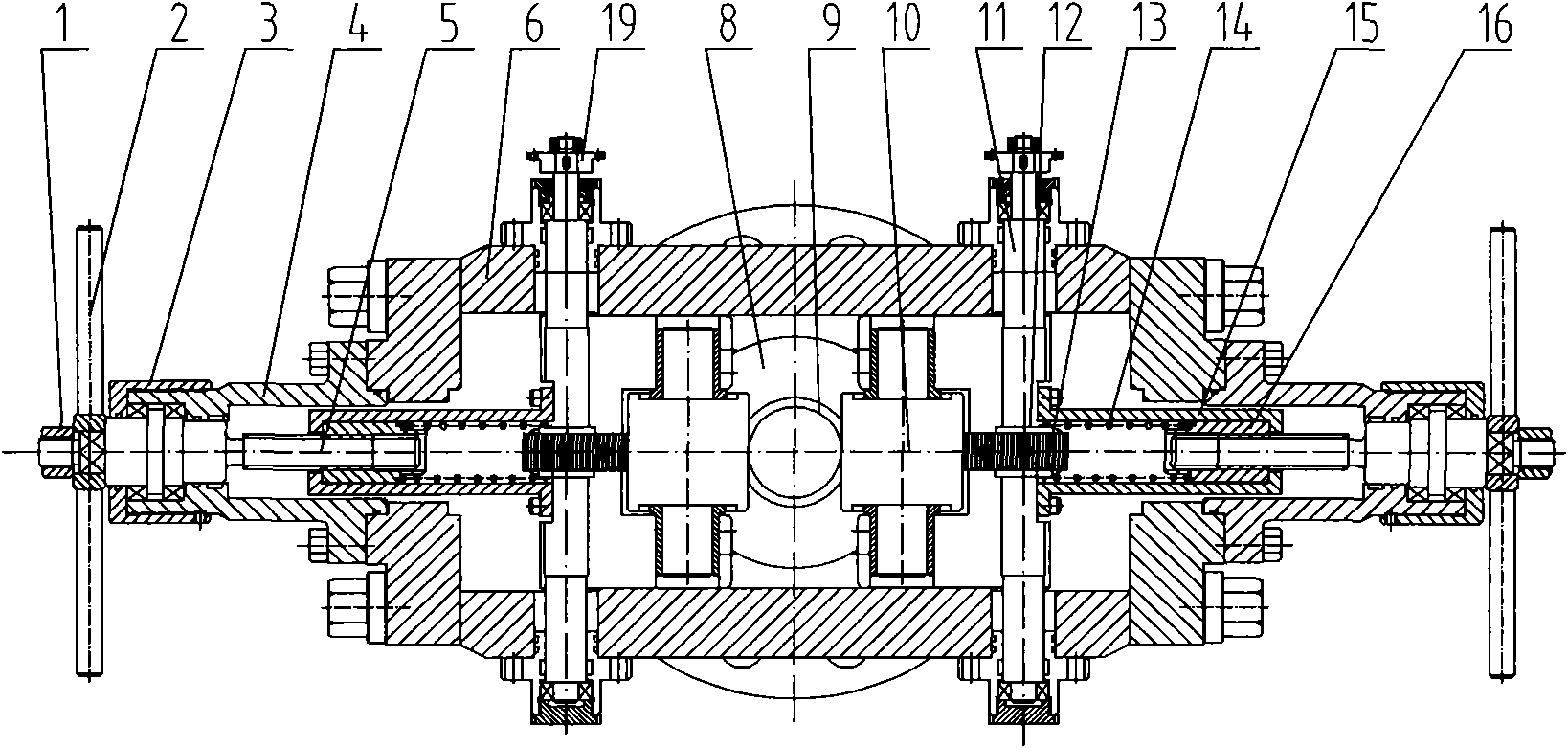

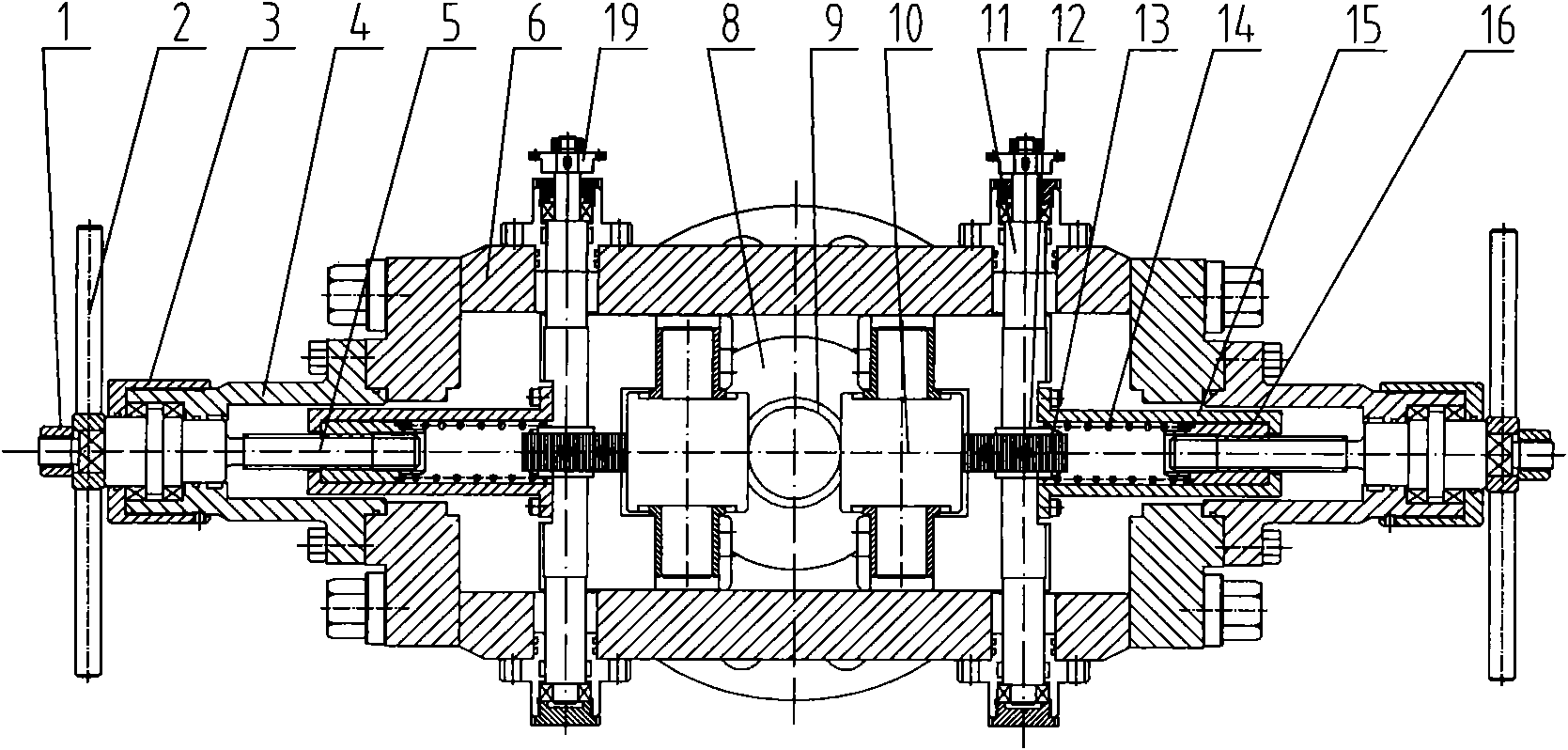

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0011] The oil pipe coupling detection device of the present invention includes a semi-closed ram blowout preventer, a coupling detection wheel 10 , a gear shaft 11 and an induction wheel 19 . The semi-enclosed ram blowout preventer includes a body 6, a shield 4, a screw 5 and a ram 7; both sides of the main diameter 8 of the body 6 are symmetrically provided with a ram cavity, and the two rams 7 Separately packed in the above-mentioned two gate cavities, the outer side of the gate cavity is sequentially equipped with a shield 4 and a pressure cap 3; the inner end of the lead screw 5 is placed in the above-mentioned gate cavity, and its outer end is equipped with a control Handle 2 and lock nut 1; drive nut 16 is installed on the inner end of lead screw 5, guide sleeve 15 is set on the outside of drive nut 16, and the outer end of guide sleeve 15 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com