Imitated oil base high-density drilling fluid

A high-density, drilling fluid technology, applied in the field of drilling fluid, can solve the problems of polluting the environment, high cost, affecting oil and gas layer display, etc., and achieve the effects of suppressing collapse, achieving wellbore stability, and good oil-based performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

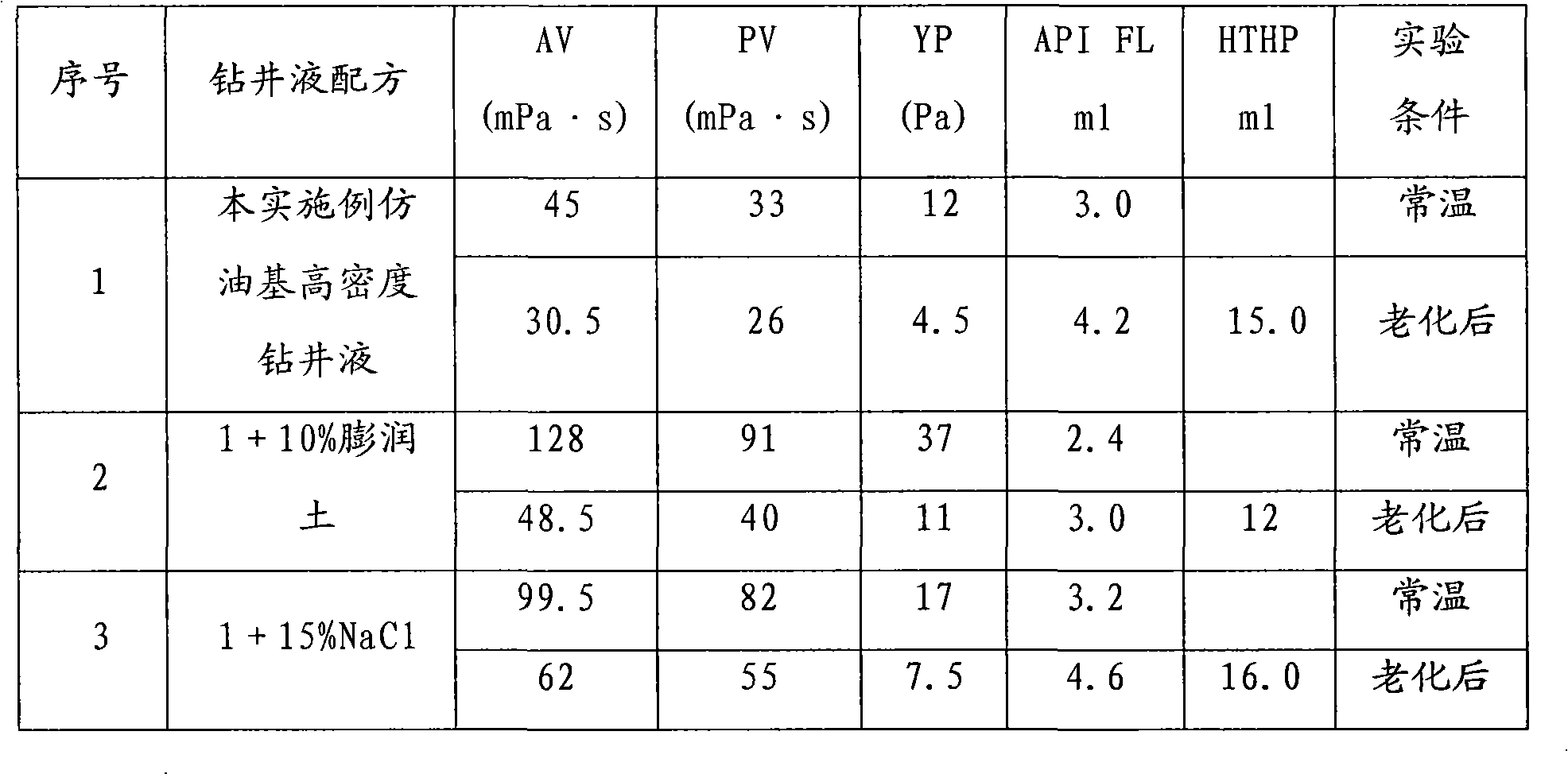

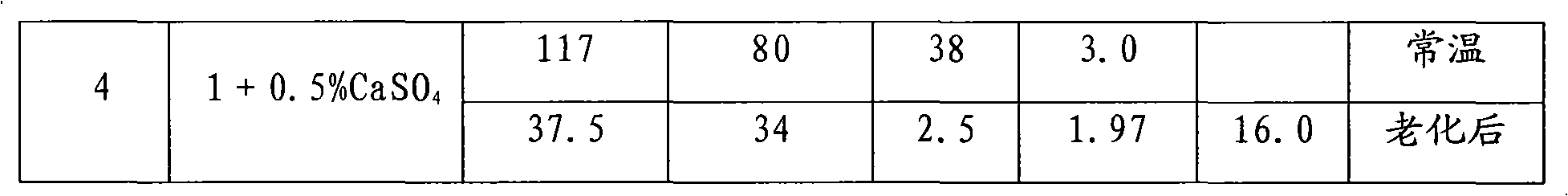

[0015] Preferred tests for in-house formulations:

[0016] 1. Base slurry selection

[0017] The base slurry required for the test is optimized, and the experimental data are shown in Table 1:

[0018] Table 1 Conventional properties of base pulp with different contents

[0019] project

AV

PV

API (mL)

2% Base pulp

2

2

34.0

3% Base pulp

3

2

27.0

4% Base pulp

5

2

21.8

[0020] Note: In the present invention, the meaning of 2% base slurry is: add 2 grams of sodium bentonite per 100 grams of water (3% base slurry, 4% base slurry, etc. have the same meanings, which are well-known expressions for those skilled in the art method, and will not be described one by one).

[0021] Reduce the solid phase content as much as possible, and at the same time take into account the two indicators of rheology and water loss. Combined with the experimental data, 3% sodium-based bentonite slurry is sele...

Embodiment 2

[0044] According to the above test data in Example 1, the formulation of the oil-based high-density drilling fluid in this example is as follows: 3% base slurry + 0.3% FA367 + 5% lubrication inhibitor + 3% SMC + 1% SPNH + 2% sulfonation Bitumen + 1% shielding temporary plugging agent + 6% KCl. The performance experimental data of the imitation oil-based high-density drilling fluid in this example is shown in Table 8:

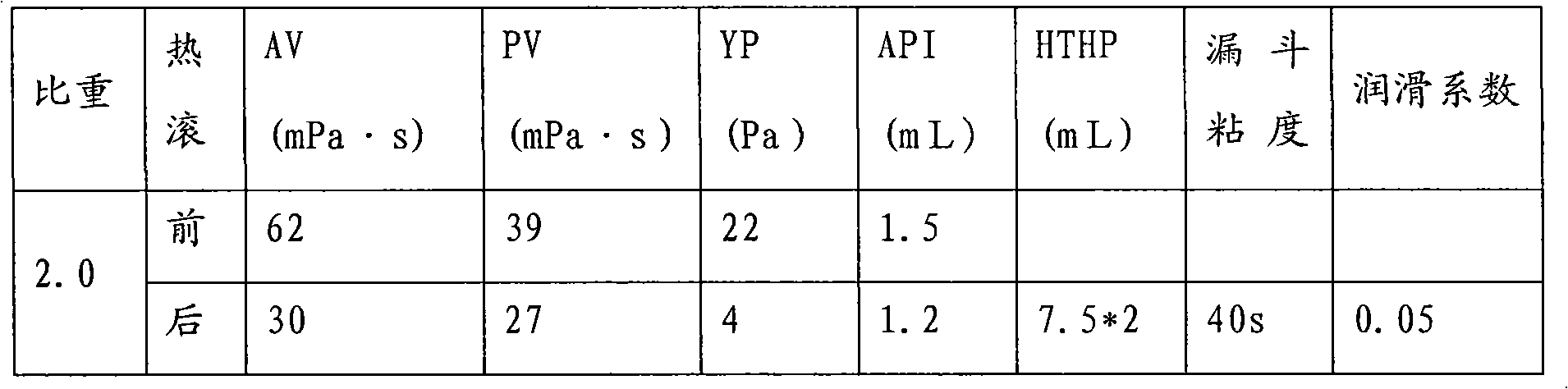

[0045] Table 8 Normal temperature and high temperature performance of imitation oil-based high-density drilling fluid in this example

[0046]

[0047] From the above data, it can be seen that the imitated oil-based high-density drilling fluid of this example can maintain good rheological and water loss properties after hot rolling at 160°C for 16 hours.

[0048] Table 9 Lubricity evaluation results of imitation oil-based high-density drilling fluid in this example

[0049] drilling fluid

Lubrication coefficient

mud cake viscosity

Im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com