Manufacture method of Z-shaped steel sheet pile through continuous cold roll forming

A manufacturing method and cold forming technology, which are applied in the field of roll-type continuous cold forming of Z-shaped steel sheet piles, can solve the problems of lack of continuous cold forming processing technology and high energy consumption of hot rolling forming, and achieve fast and flexible delivery. , the effect of high production efficiency and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0051] Such as Figure 1-6 shown.

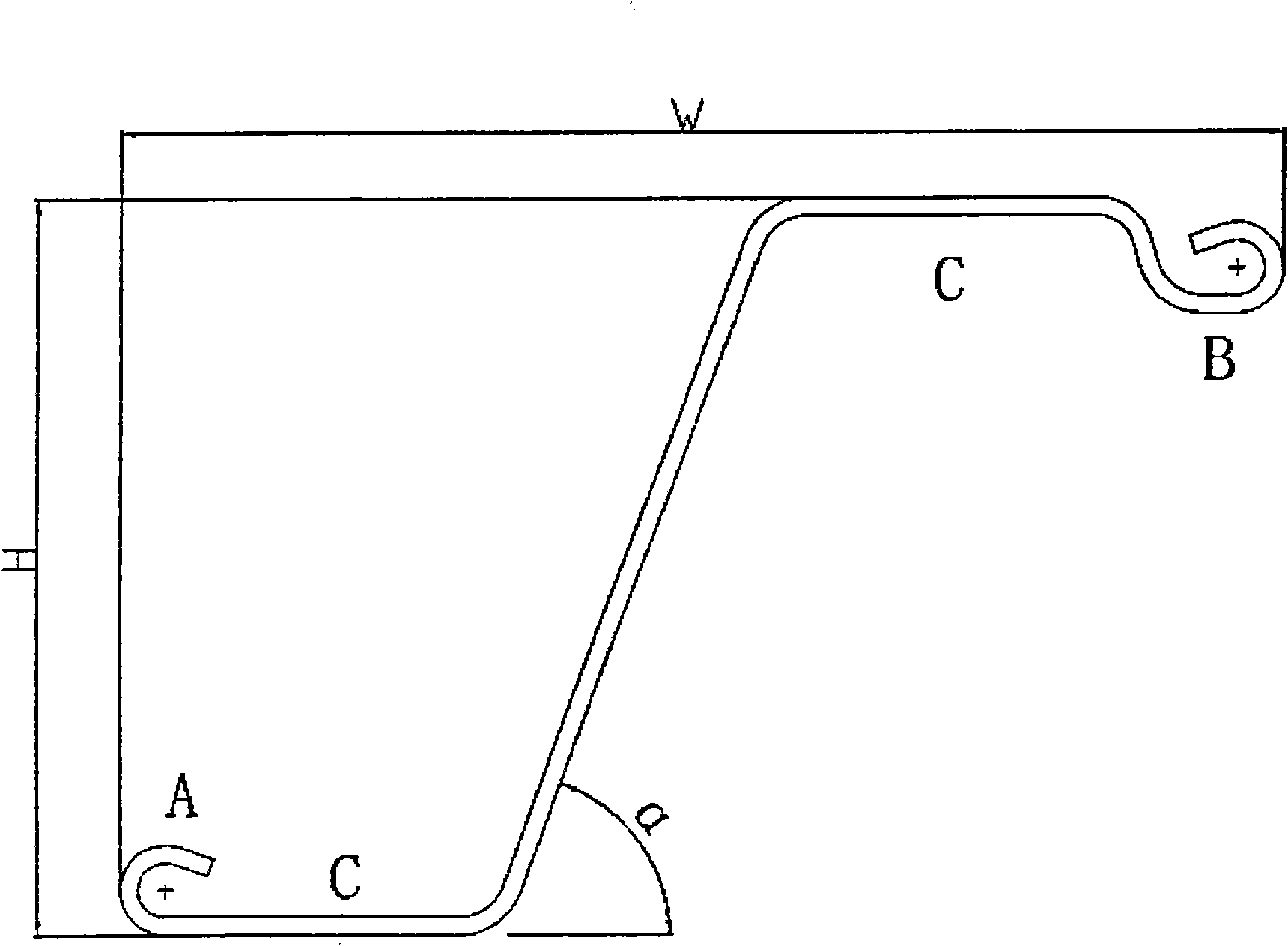

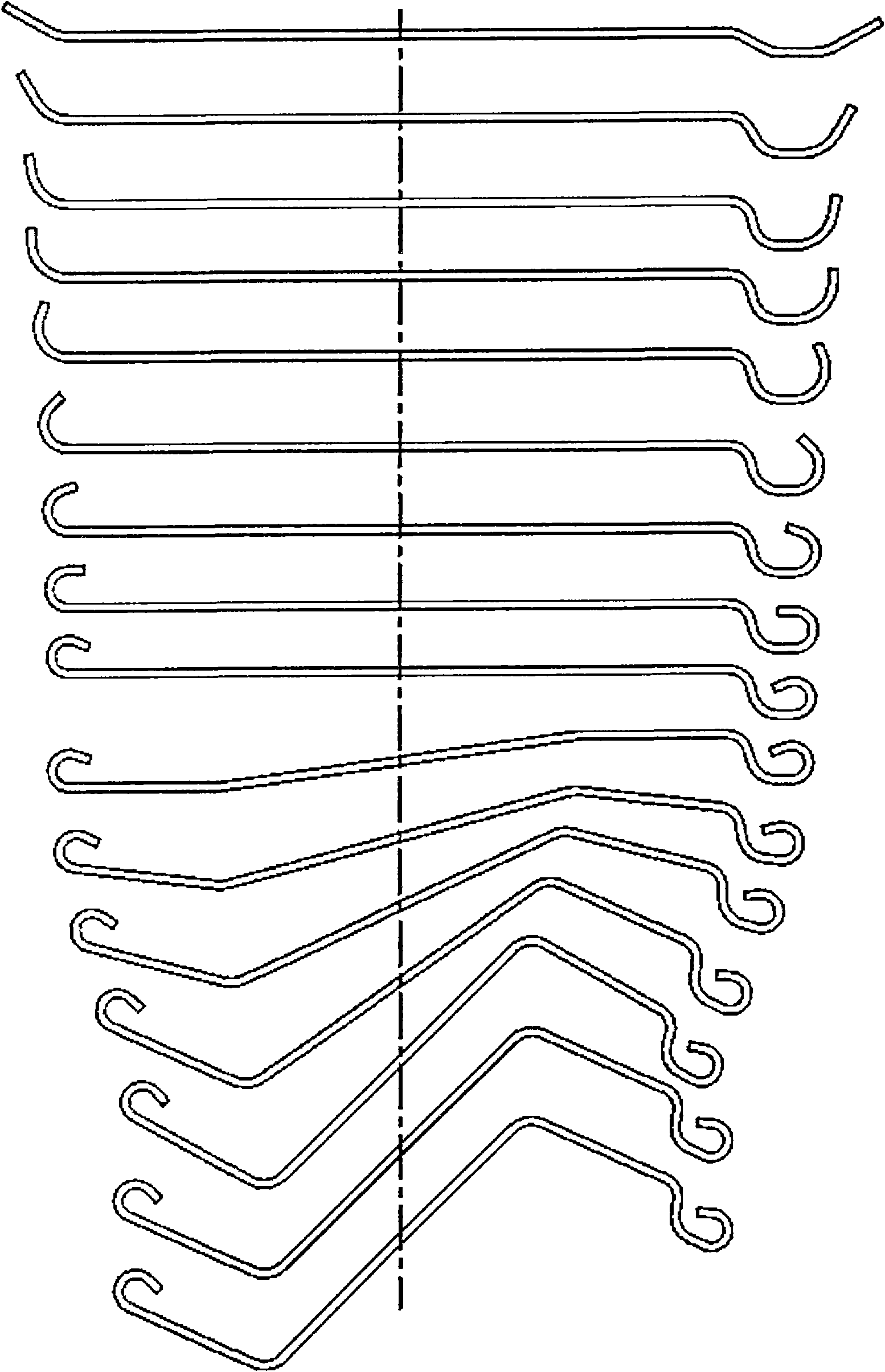

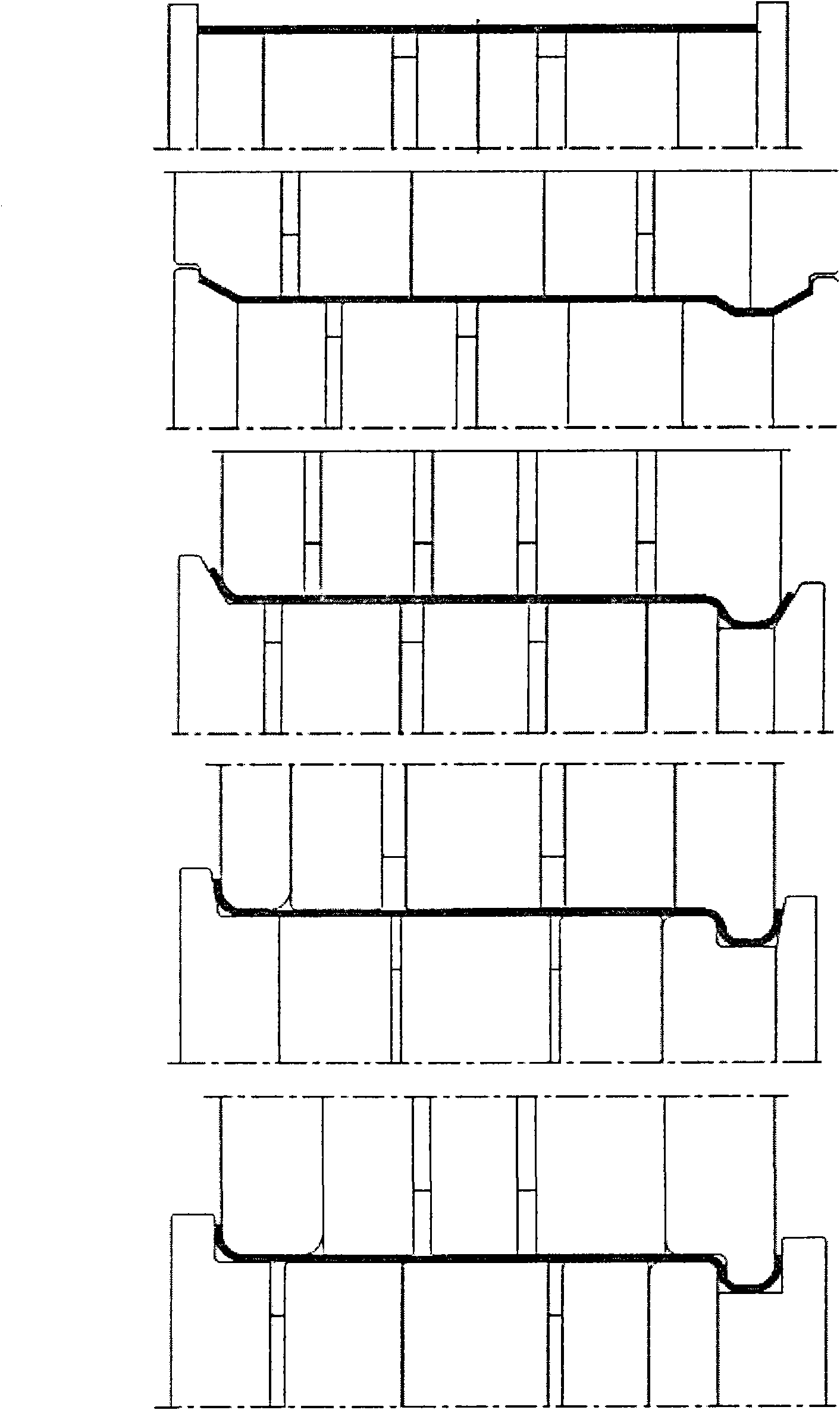

[0052] A Z-shaped steel sheet pile, whose cross-section is a Z-shaped structure, it is provided with two locks A, B and two waists C, such as figure 1 As shown, it can be used Figure 3-6 Shown is the method and continuous rolling die for continuous cold roll forming. The continuous deformation process of the steel plate during the forming process is as follows: figure 2 shown. For the roller forming molds of each process, please refer to Figure 3-6 To be designed, the key to continuous cold bending is the selection of the deformation process and method, and the deformation angle. The specific manufacturing process includes:

[0053] 1. Slitting strip steel

[0054] The hot-rolled coil is slit into the width designed by the process on the slitting unit

[0055] 2. Uncoiling and leveling

[0056] The hot-rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com