Adjustable-height bracket base for photovoltaic array bracket

A photovoltaic array and adjustable technology, applied in the field of brackets, can solve the problems of increasing construction difficulty, height error, increasing installation cost and time, etc., so as to reduce installation and construction difficulty, save installation cost and time, and avoid secondary grouting. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

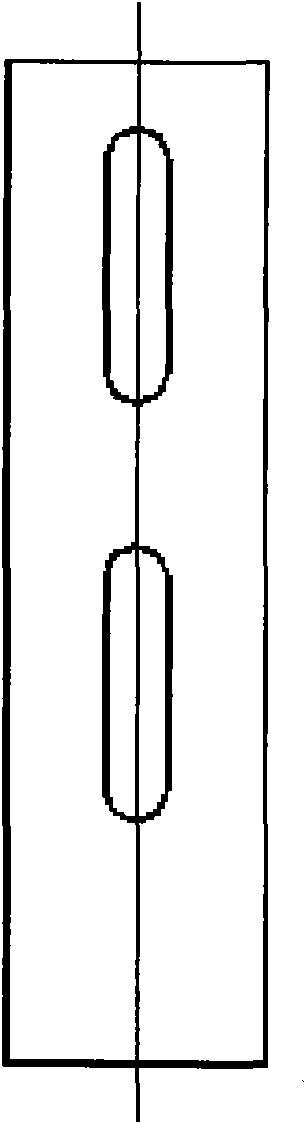

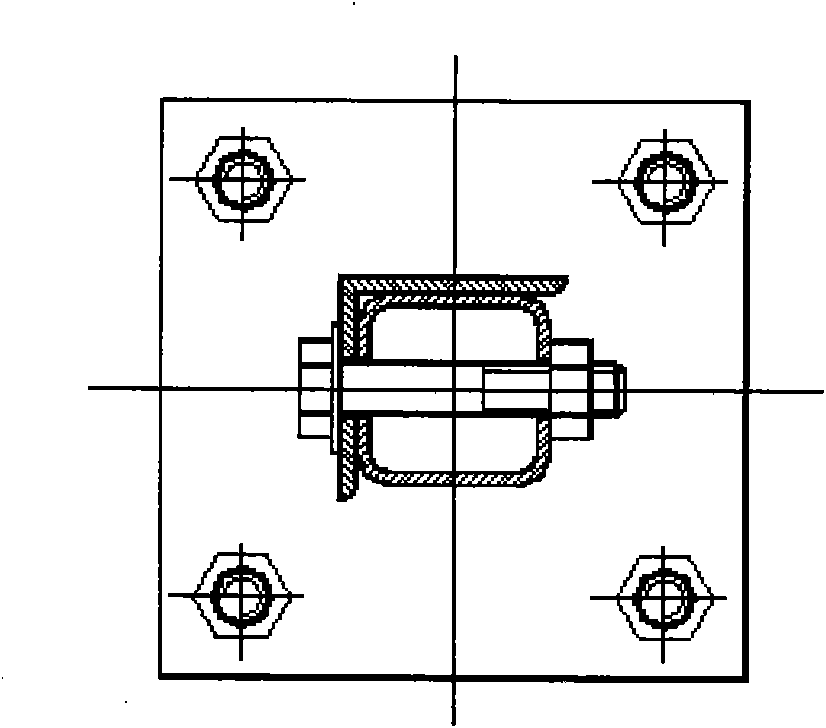

[0053] figure 1 It is the front view of the height-adjustable bracket seat of this embodiment, figure 2 It is the left view of the height-adjustable bracket seat of this embodiment, image 3 It is a top view of the height-adjustable bracket seat of this embodiment.

[0054] The support pole A is composed of a rectangular tube. There are two piercing screw holes on the vertical surface of the support pole. An end plate H with holes is welded at the lower end of the support pole, such as Figure 8 shown. The bracket base B is composed of C-shaped steel, such as Figure 4 As shown, two vertical waist holes are opened on the vertical surface of the bracket base B, and the bracket base B is directly welded on the bottom plate E. The fastening bolt F connects the support pole A to the support base B through the said through screw hole. Such as Figure 11 , Figure 12 As shown, the bottom plate E is a rectangular plate with four circular fixing screw holes, the adjusting bolt...

Embodiment 2

[0057] Figure 17 It is a top view of the height-adjustable bracket seat of the second embodiment. The support pole is composed of a rectangular tube, and there are two opposite screw holes on the vertical surface of the support pole, and an end plate with holes is welded at the lower end of the support pole, such as Figure 8 shown. The bracket base is composed of channel steel, such as Figure 7 As shown, two vertical waist holes are opened on the vertical surface of the support base, and the support base is directly welded on the bottom plate. The fastening bolt connects the support pole with the support base through the said through screw hole. Such as Figure 13 , Figure 14 As shown, the bottom plate E is a rectangular plate with four circular fixing screw holes, the adjusting bolts are common bolts, and the adjusting bolts are directly welded to the bottom plate.

[0058] When installing, first turn the adjusting nut to adjust the height of the support pole, and the...

Embodiment 3

[0060] Figure 18 It is a top view of the height-adjustable bracket seat of the third embodiment. The support pole is composed of a rectangular tube, and there are two vertical waist holes on the vertical surface of the support pole, and an end plate with a hole is welded at the lower end of the support pole, such as Figure 9 shown. The bracket base is composed of angle steel, such as Figure 6 As shown, there are two through screw holes on the vertical surface of the support base, and the support base is directly welded on the bottom plate. The fastening bolt connects the support pole with the support base through the said through screw hole. Such as Figure 15 , Figure 16 As shown, the bottom plate E is a rectangular plate with four circular fixing screw holes, the adjusting bolts are common bolts, and the adjusting bolts are embedded in the hexagonal holes opened on the bottom plate.

[0061] When installing, first turn the adjusting nut to adjust the height of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com