Geomechanics model layering compaction air drying manufacturing and grooving embedding tester method

A test instrument and geomechanics technology, which is applied in the field of geomechanics model layered compaction and air-dried production and grooving and embedding test instruments, can solve the problem of inability to ensure the compactness of the model body, the inability to ensure the compactness of the overall structure of the model, and the inability to ensure the integrity of the model Structural uniformity and other issues to achieve the effect of improving the production process and testing technology level, reducing interference, and ensuring homogeneity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

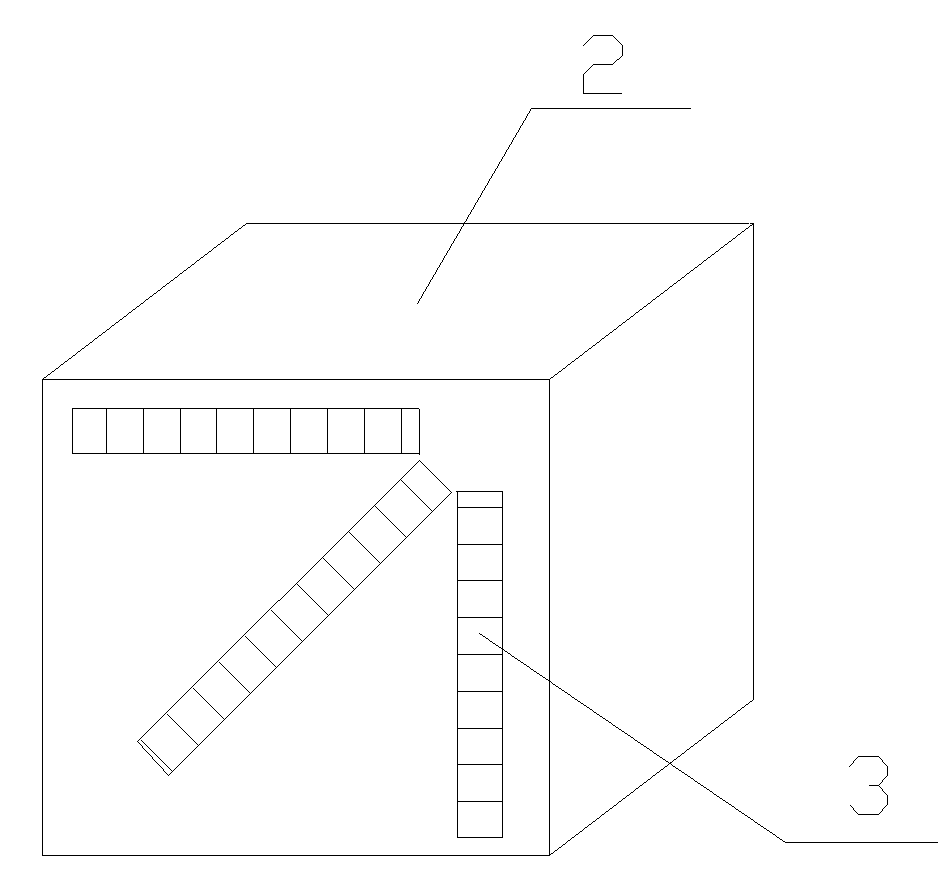

[0042] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0043] A geomechanical model layered compaction air-drying manufacturing and cutting groove embedding test instrument method, comprising the following steps:

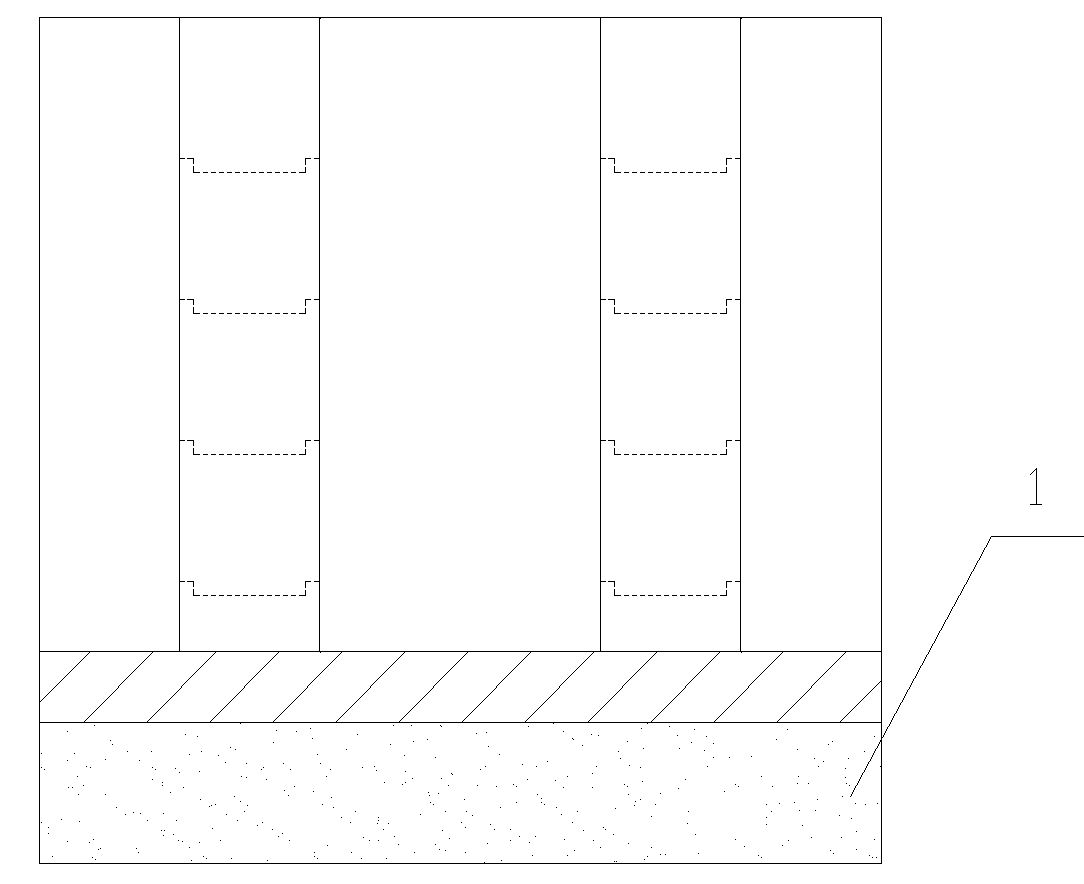

[0044] 1) Determine the pressure required for compacting the model body 1 . In order to ensure the mechanical parameters of model body 1, such as elastic modulus E, compressive strength σ c , tensile strength σ t , Poisson's ratio μ, etc. reach the design value, which is equal to the test value of the mechanical parameters of the model material laboratory, and it is necessary to ensure that the pressure of the model body 1 when pressing is equal to the pressure when pressing the test piece, so the pressing force of the model body 1 is S·σ p , where S is the cross-sectional area of the model body, σ p For making the pressure of standard test piece (the pressure of this making standard test pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com