Vertical self-priming centrifugal pump self-supply water-cooling mechanical sealing structure

A technology of mechanical seal and centrifugal pump, applied in the field of self-contained water-cooled mechanical seal structure of vertical self-priming centrifugal pump, can solve problems such as dry friction of friction pair, achieve reliable water cooling, improve service life and good water cooling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below according to the accompanying drawings and examples.

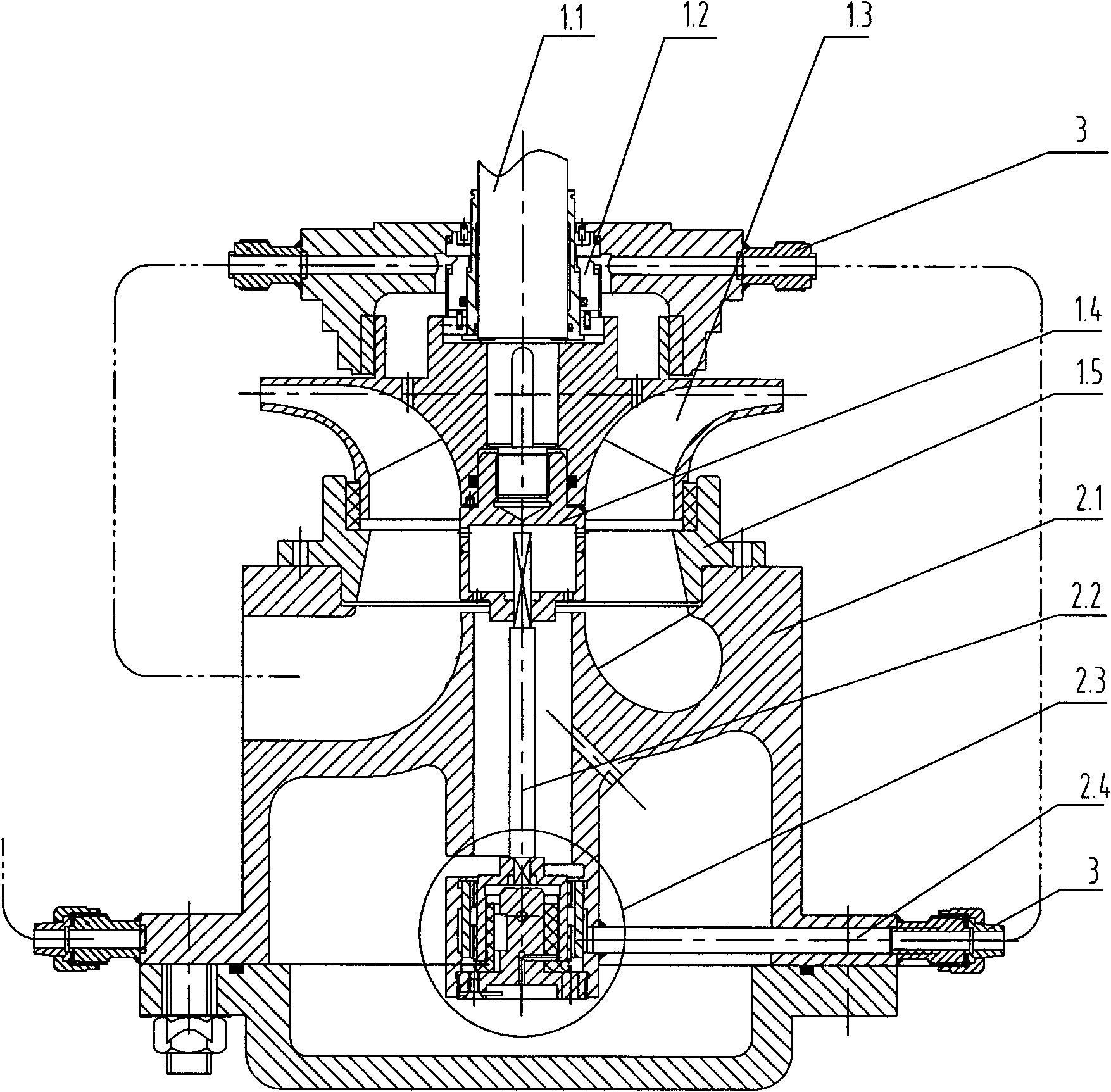

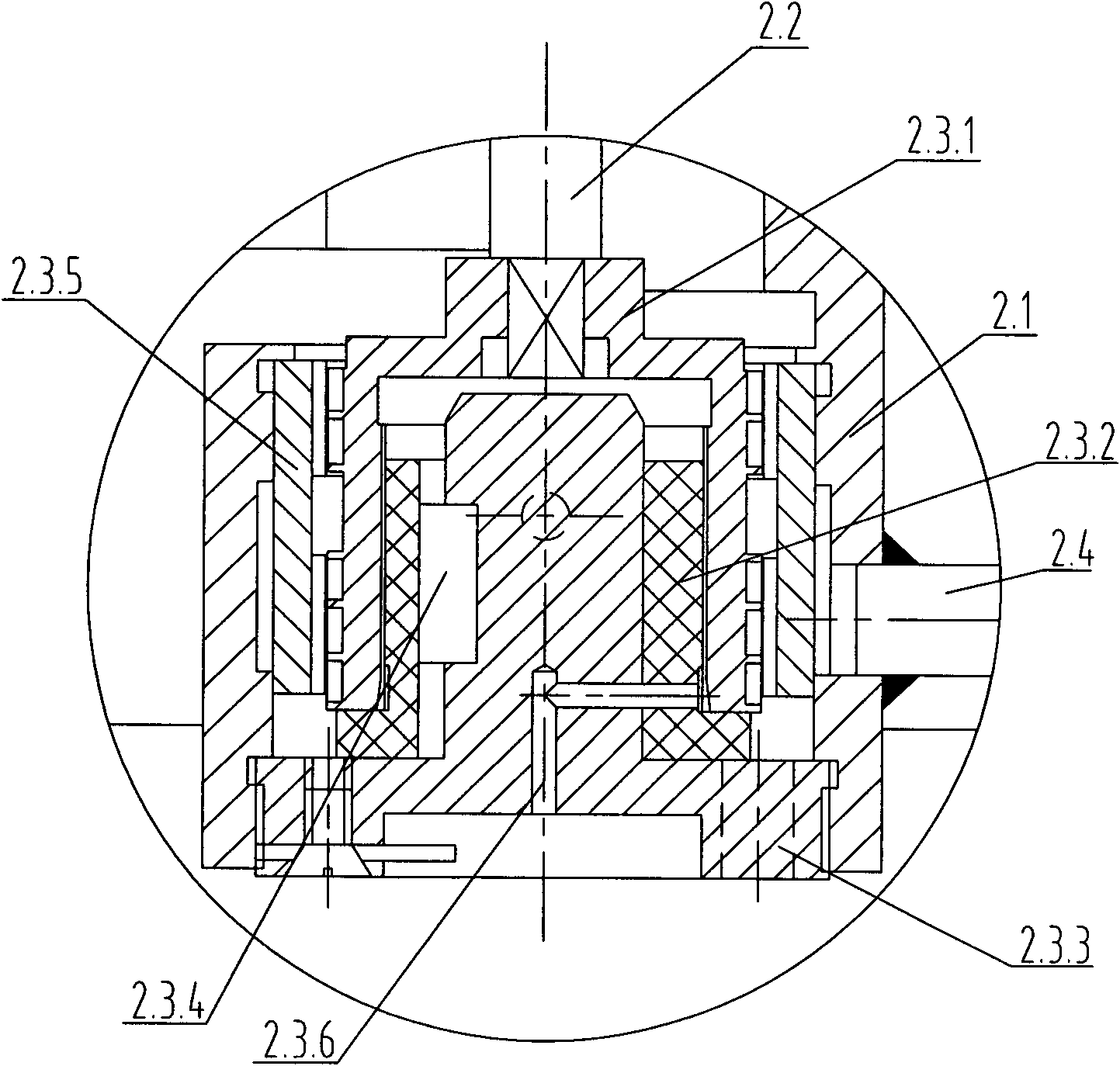

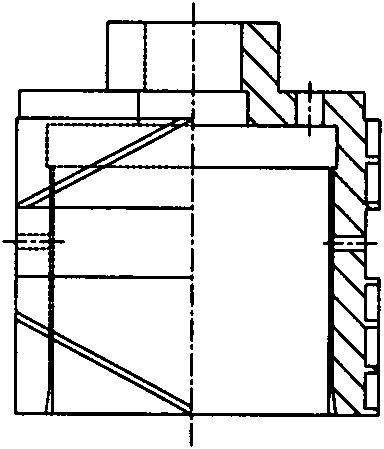

[0019] figure 1 The self-contained water-cooled mechanical seal structure of the vertical self-priming centrifugal pump shown includes three parts: the pump shaft seal, the pressurized water assembly and the connecting pipe. The pump shaft seal is located on the top of the impeller 1.3, and it includes a mechanical seal 1.2 equipped with a vertical pump shaft 1.1, an impeller 1.3, a lock nut 1.4, and a flange 1.5 matched with the impeller 1.3. The present invention is provided with a pressurized water assembly at the bottom of the pump shaft seal, and its housing 2.1 is a water storage container with a bottom, and the upward end face is connected with the pump shaft seal through a flange 1.5. The transmission shaft 2.2 is respectively connected with the lock nut 1.4 and the inner ring 2.3.1 through tenon structures at both ends, forming a structure in which the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com