Device used for connecting curtain wall aluminum alloy cross beam with upright

An aluminum alloy beam, aluminum alloy technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of low installation accuracy, waste of human resources, and affect the appearance, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with specific drawings and examples.

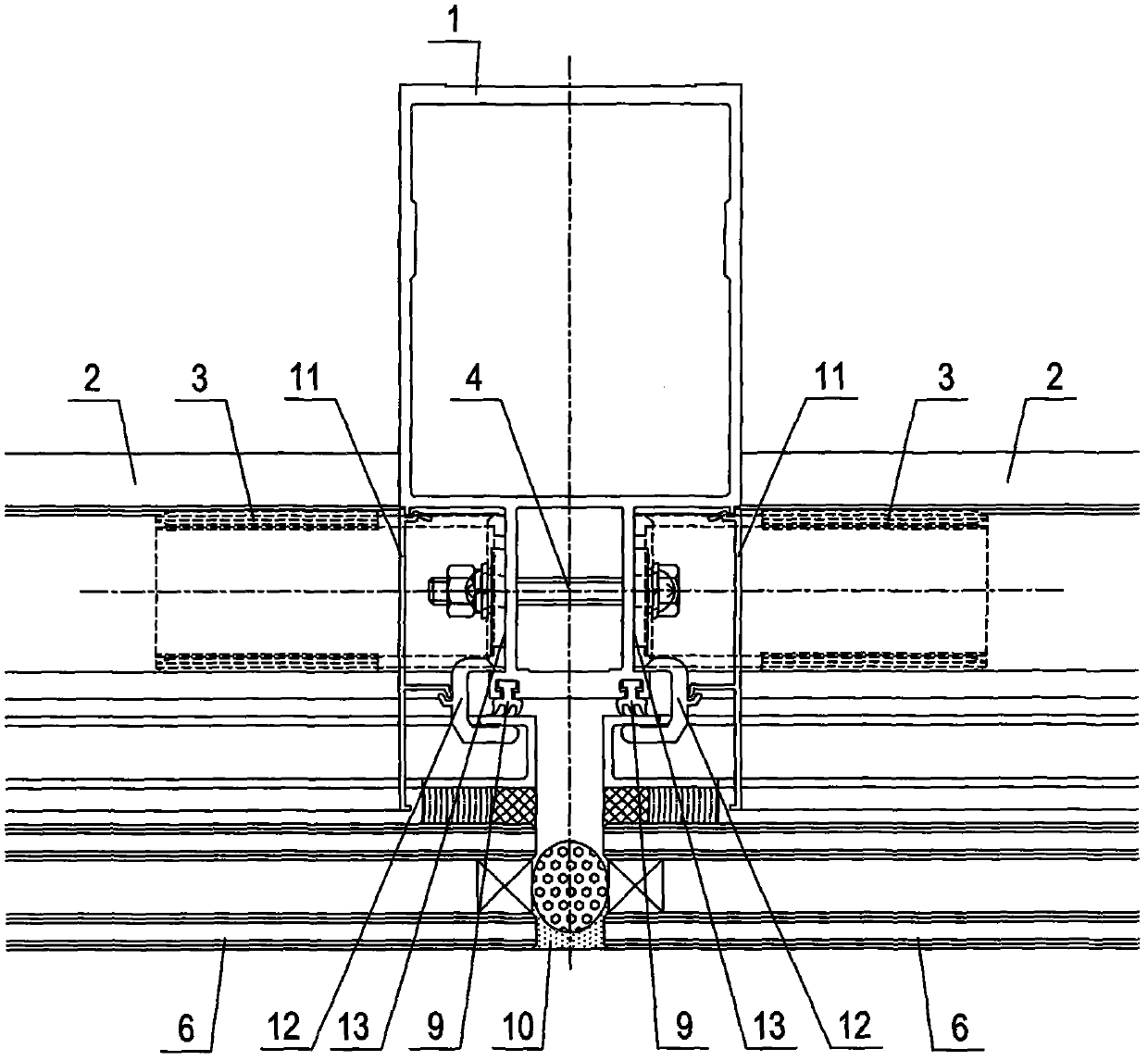

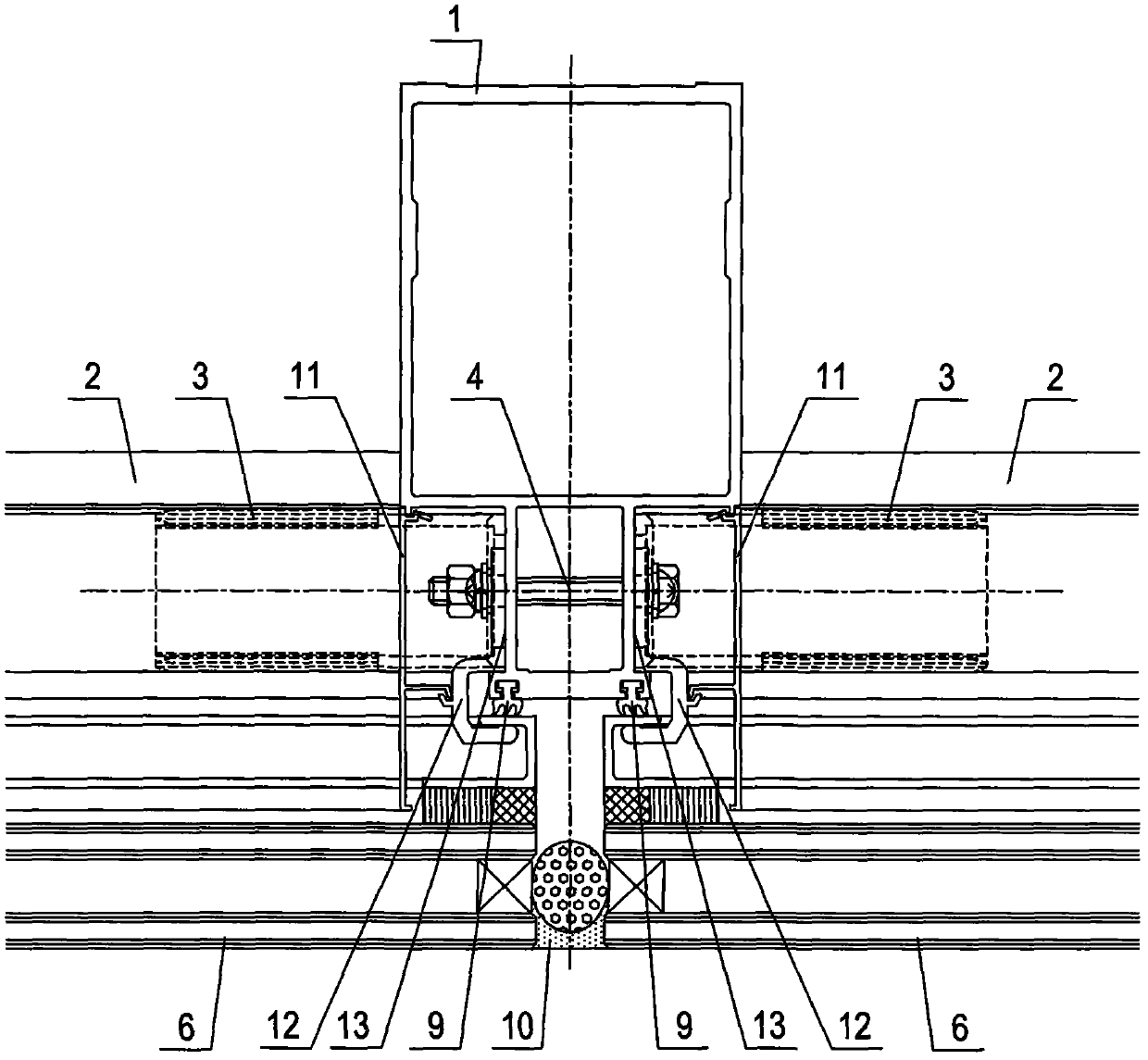

[0012] Such as Figure 1 ~ Figure 2 As shown, the device connecting the aluminum alloy beams and aluminum alloy columns of the curtain wall includes aluminum alloy columns 1, aluminum alloy beams 2, aluminum alloy corner brackets 3, hexagonal bolts 4, aluminum alloy horizontal decorative covers 5, glass and aluminum alloy composite plates 6, Pan head bolt 7, aluminum alloy connector 8, rubber strip 9, silicone sealant 10, aluminum alloy vertical decorative cover 11, aluminum alloy hook block 12 and limiting groove 13 on the aluminum alloy column.

[0013] The present invention is divided into two steps of factory production and site construction and installation. The factory production first processes the aluminum alloy column 1 and the aluminum alloy beam 2, and then inserts the rubber strip 9 into the groove on the aluminum alloy column 1 and the aluminum alloy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com