Energy-saving low-temperature multiple-effect seawater desalting device

A seawater, low temperature technology, applied in seawater treatment, general water supply saving, water/sewage treatment and other directions, can solve the problems of equipment stability, high steam heat source price, expensive evaporator materials, etc., to reduce costs and save energy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

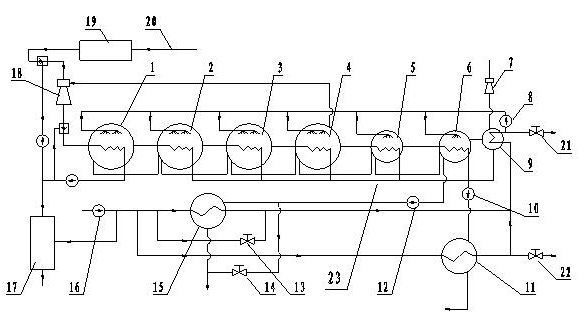

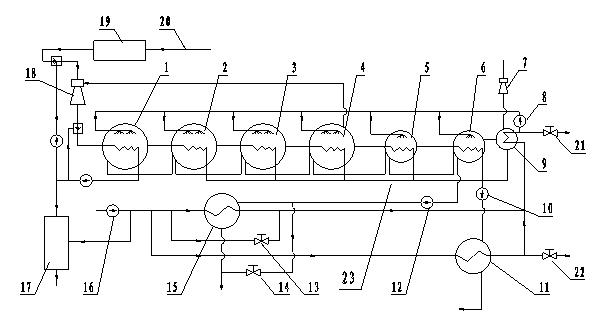

[0012] see figure 1 , the present invention comprises a heat source, a steam injector 18, a one-effect evaporator 1, a second-effect evaporator 2, a three-effect evaporator 3, a four-effect evaporator 4, a five-effect evaporator 5, a six-effect evaporator 6, a vacuum The injector 7, the condenser 9, and the above-mentioned six-effect evaporator are connected in series. In order to save energy and reduce operating costs, the heat source of the present invention includes a steel plant flue gas pipeline 20 and a waste heat boiler 19, and the waste heat boiler 19 is used to convert the exhaust gas of the steel plant into saturated steam and superheated steam, and the saturated steam and superheated steam are injected by steam The device 18 is sent into the one-effect evaporator 1, and the outlet of the six-effect evaporator 6 is connected to the condenser 9.

[0013] still refer to figure 1 , the present invention is also provided with raw material seawater heat exchange part, d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com