Weight packing and conveying device

A technology for transporting devices and weights, applied in the field of measurement, which can solve problems such as inconvenient transportation, inconsistent heights, and high labor intensity, and achieve the effects of preventing radiation effects, preventing electromagnetic radiation, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

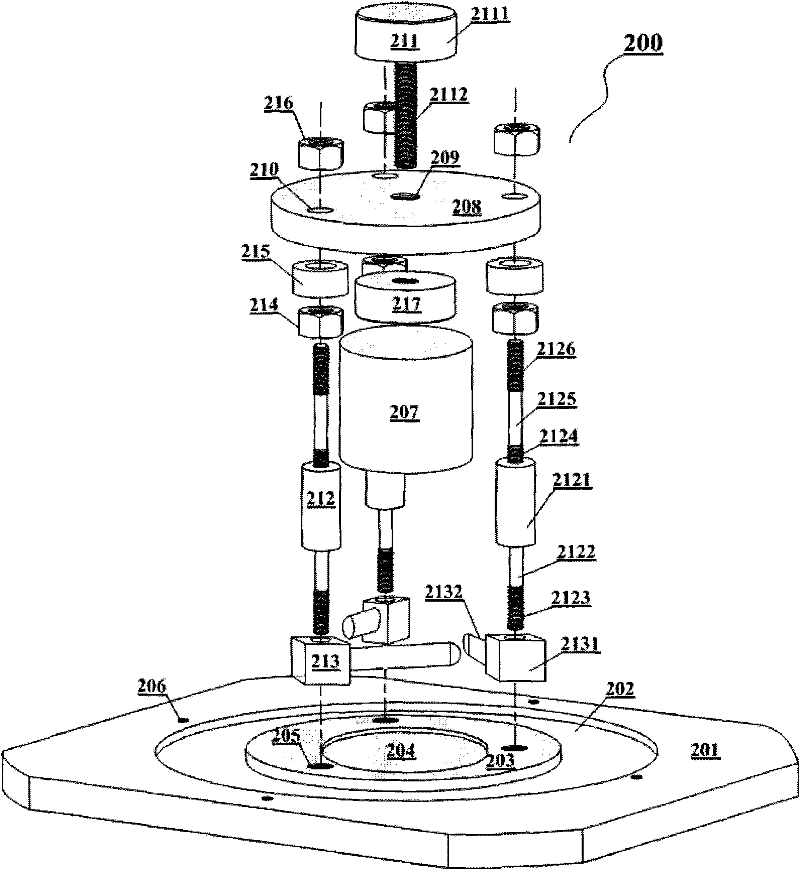

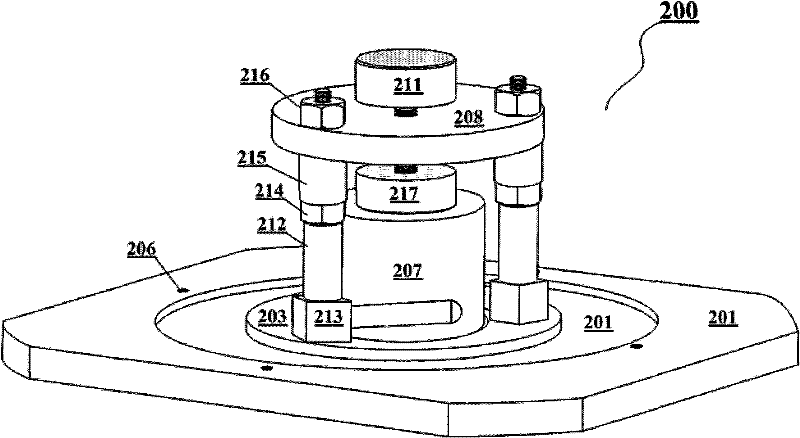

[0033] A weight packaging and transporting device, the packaging and transporting device includes a bottom support 201 carrying the weight transporting device, a weight to be transported 207, an upper part of the weight covering the weight top cover 208, and a tightening mechanism for tightening the weight , a mechanism for fixing the weight and supporting the top cover, an outer cover 300 for containing the weight, and a pressure ring 400 for preventing the outer cover from moving. Wherein, the bottom bracket 201 is formed with an annular groove 202, and there is a circular boss 203 in the middle of the bottom bracket. The center of the circular boss 203 is a circular receiving groove 204, the diameter of which is smaller than the diameter of the weight to be packaged. Slightly larger, it is used to place packaged weights. The circular boss 203 outside the circular receiving groove 204 has at least three threaded holes 205 evenly distributed along the circumference. There are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com