Rapid tool changing mechanical arm with electric drive pusher

A technology of electric push rod and electric push rod, which is applied to metal processing mechanical parts, clamping, support and other directions, can solve the problems of high structural complexity, low reliability, not suitable for high-speed tool change, etc., and achieves reliable driving and installation. The effect of small maintenance workload and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

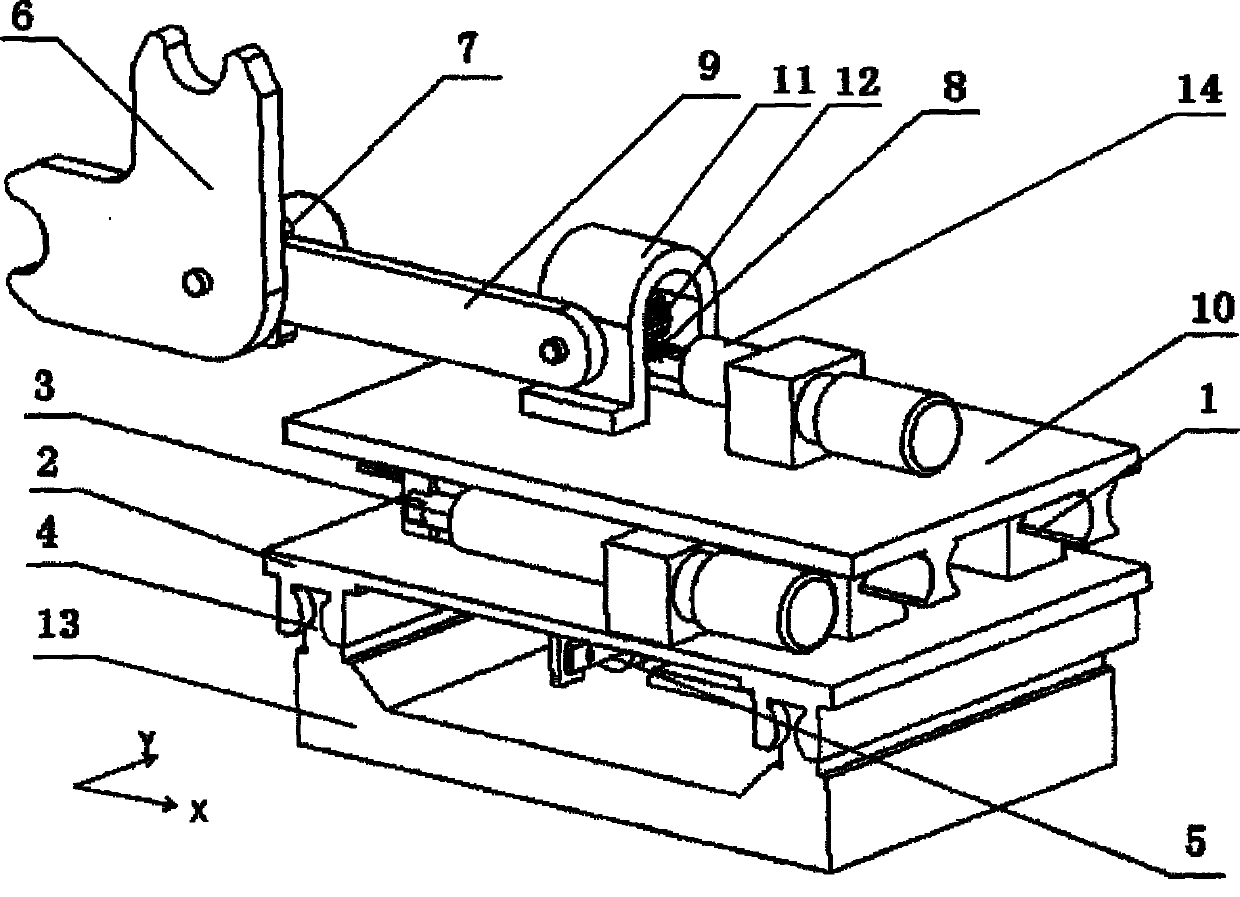

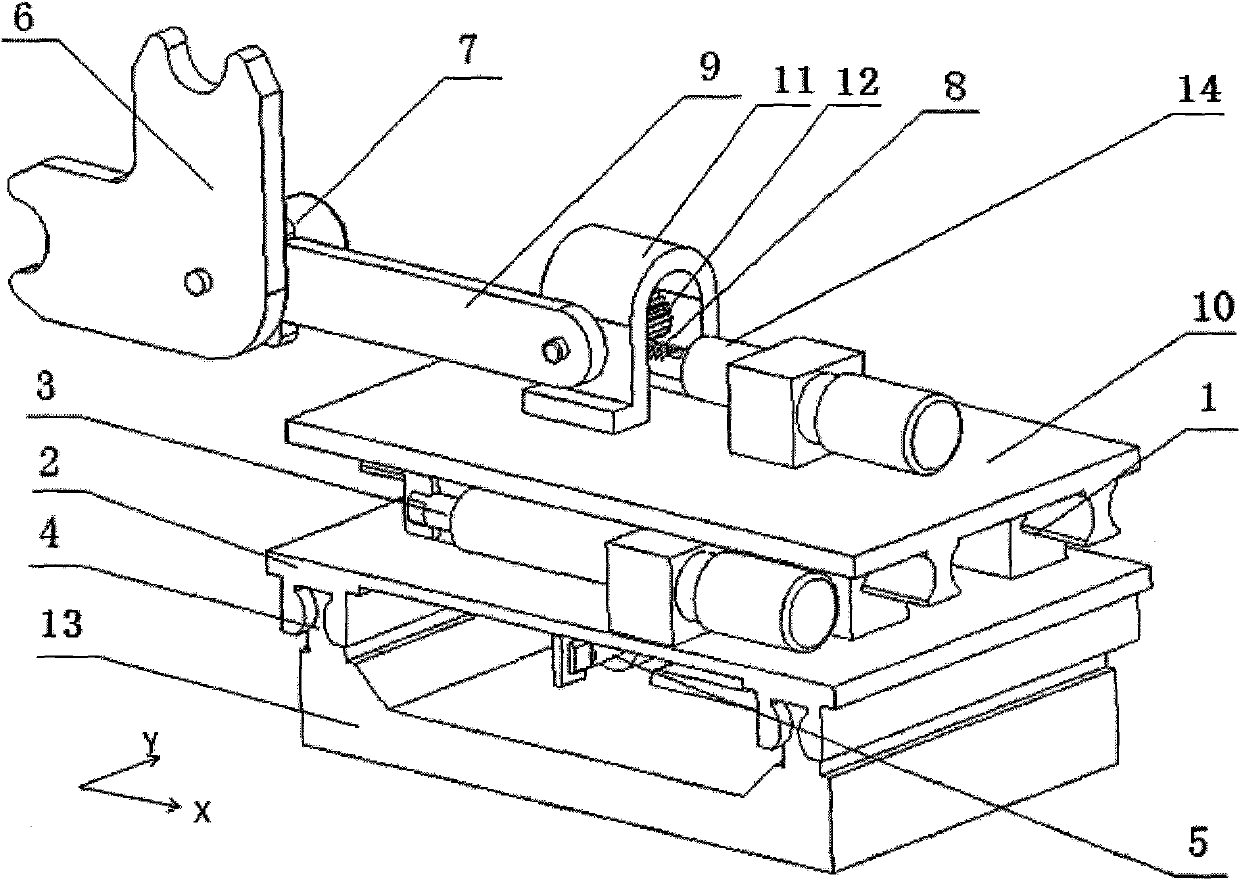

[0009] The structure of the structure of the manipulator tool changing mechanism is as shown in the accompanying drawings. It is characterized in that it includes a manipulator swinging device composed of a third motor push rod 14, a gear 12 and a rack 8. The manipulator swinging device is realized by opening a rack on the electric push rod through a rack and pinion structure. The manipulator swing device is installed on the second linear guide pair 1 (that is, the X-axis linear guide pair) through the second sliding seat 10, and is connected with the second electric push rod 3 installed on the first sliding seat 2. The first sliding seat 2 Installed on the first linear guide pair 4 (that is, the Y-axis linear guide pair), and connected with the first electric push rod 5: the manipulator swing device includes a manipulator 6, which ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com