Forging die for manufacturing high-precision micro-vehicle crank shafts and manufacturing method thereof

A high-precision, crankshaft technology, used in the manufacture of tools, forging/pressing/hammer devices, forging/pressing/hammering machinery, etc., can solve the problems of shortening the service life of the mold, increasing the production cost, lack of guiding mechanism, etc. Service life, production cost saving, high filling and fullness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

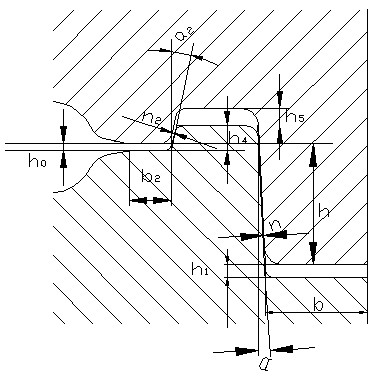

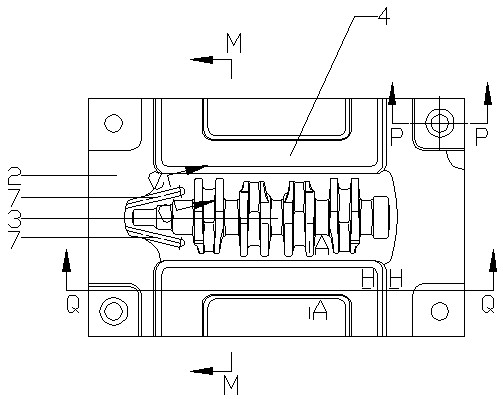

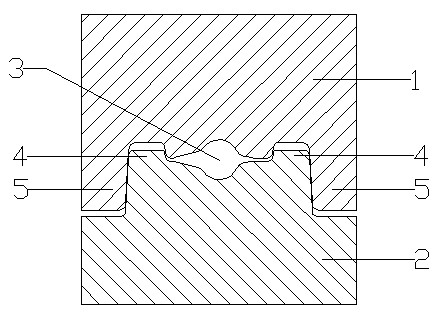

[0023] attached figure 1 It is the structural representation of the lower die of the present invention, with figure 2 to attach figure 1 Middle M-M sectional view (rotation) diagram, attached image 3 to attach figure 1 Middle A-A sectional view (rotation) diagram, attached Figure 4 to attach figure 1 Middle P-P sectional view, attached Figure 5 to attach figure 1 Middle Q-Q sectional view, attached Figure 6 to attach figure 1 Middle H-H sectional view, attached Figure 7 to attach figure 1 Middle C-C sectional view (rotation) diagram. As shown in the figure, the forging mold for manufacturing high-precision micro-car crankshaft of the present invention includes an upper mold 1, a lower mold 2 and a mold cavity 3 surrounded by the upper mold and the lower mold, and the lower mold 2 is located in the mold cavity 3 Guide grooves I are arranged axially on both sides, guide lugs I5 are arranged axially on both sides of the mold cavity on the upper mold 1 , and resis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com