Portable power tool with indicating means for actual operation parameter values

A grinding machine, parameter value technology, applied in the direction of registering/indicating machine work, registering/indicating, machine/engine, etc., can solve problems such as high cost, loss of running time indication, production interference grinding machine repair, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

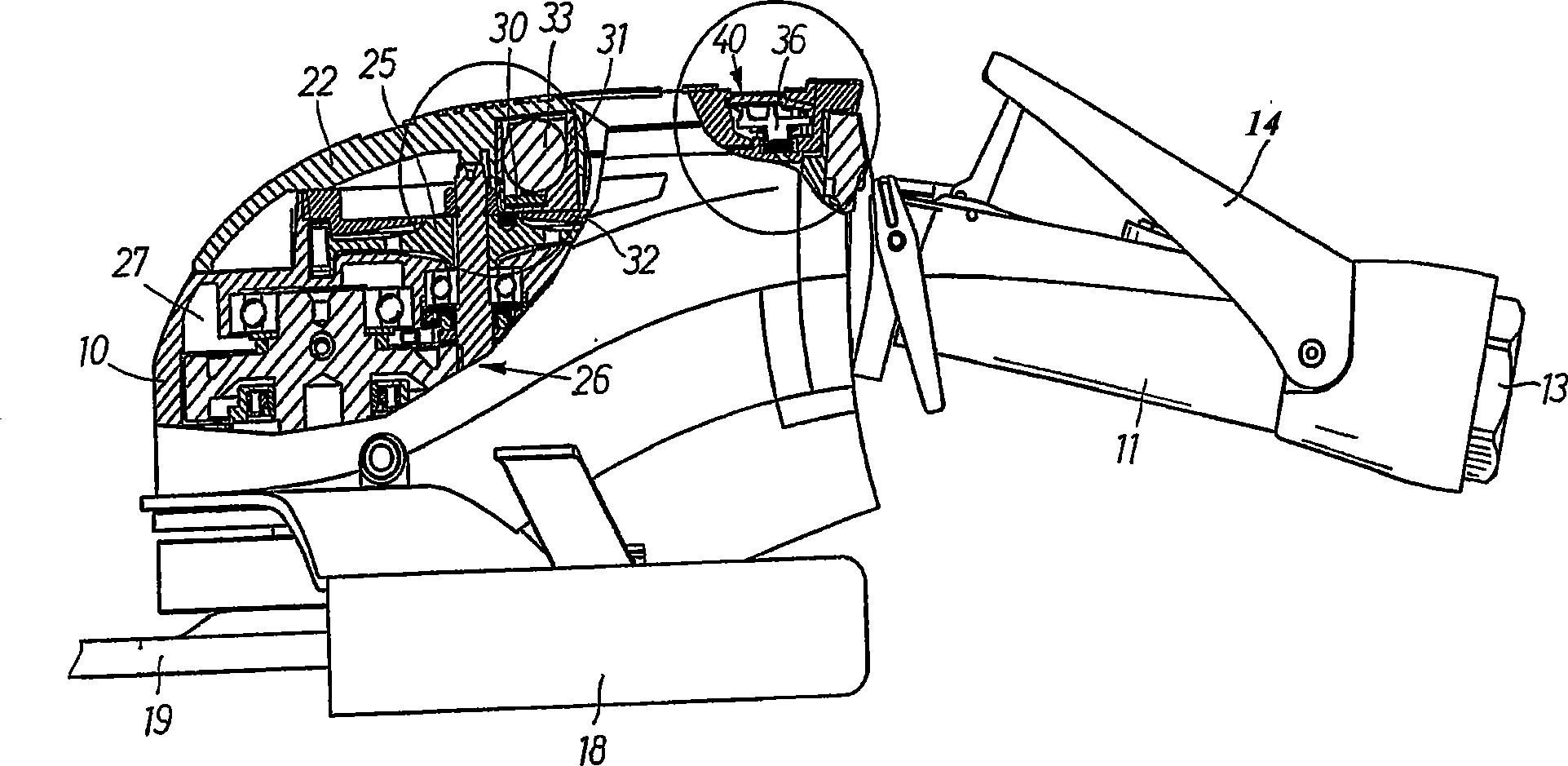

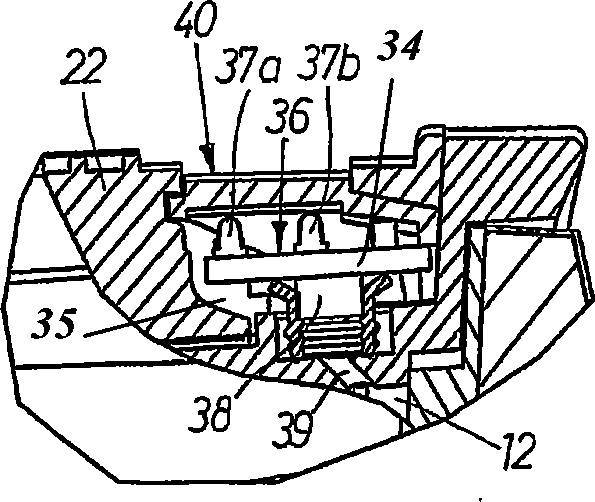

[0013] The drawing shows a portable air grinder comprising a housing 10 with a rear handle 11 forming a compressed air supply channel 12 . The handle 11 has at its rear end a connection socket 13 for a compressed air line and includes an air throttle operated by a control lever 14 . The housing 10 also carries a support handle 17 and a safety cover 18 which partially surrounds a grinding wheel 19 connected to a not shown output shaft of the tool. The housing 10 also includes a top cover 22 connected to the main body of the housing 10 by four screws 23 .

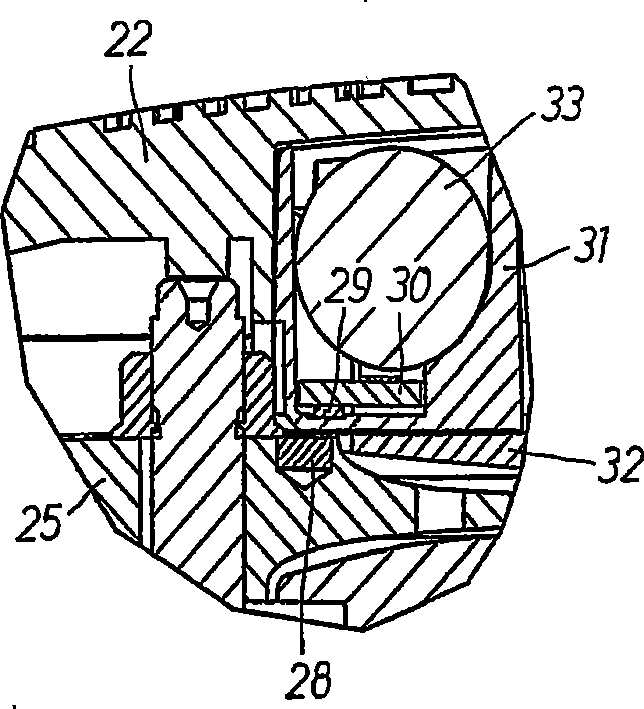

[0014] The power grinder also includes a rotating electrical machine in the form of a single-stage turbine comprising a turbine wheel 25 and an oil-lubricated reduction gear 26 . Very fast turbine wheel speeds must be slowed down to safely drive standard grinding wheels, and the lubrication and cooling issues of this high speed transmission 26 require lubricating oil rather than grease. The transmission 26 is enclosed in a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com