Prediction Method of Remaining Life of Flight Control Computer System

A flight control computer and life prediction technology, applied in hardware monitoring and other directions, can solve the problem of not having download data, etc., to avoid economic losses, reduce computing costs, and optimize maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

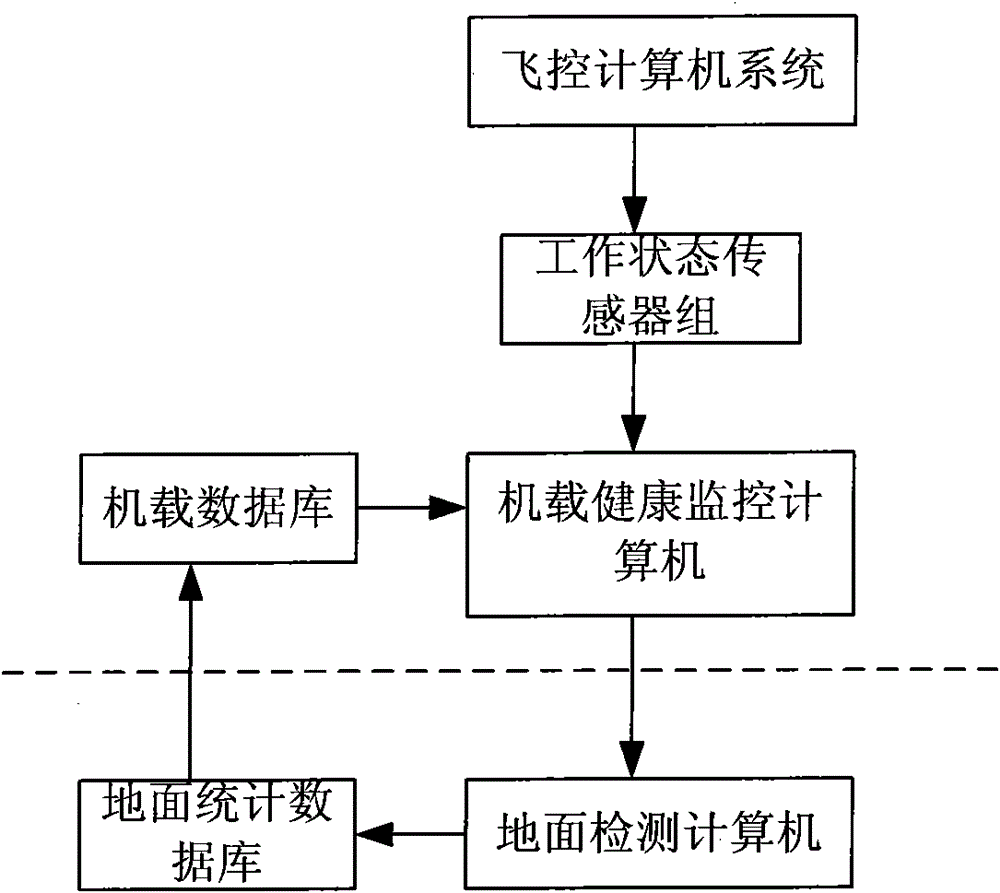

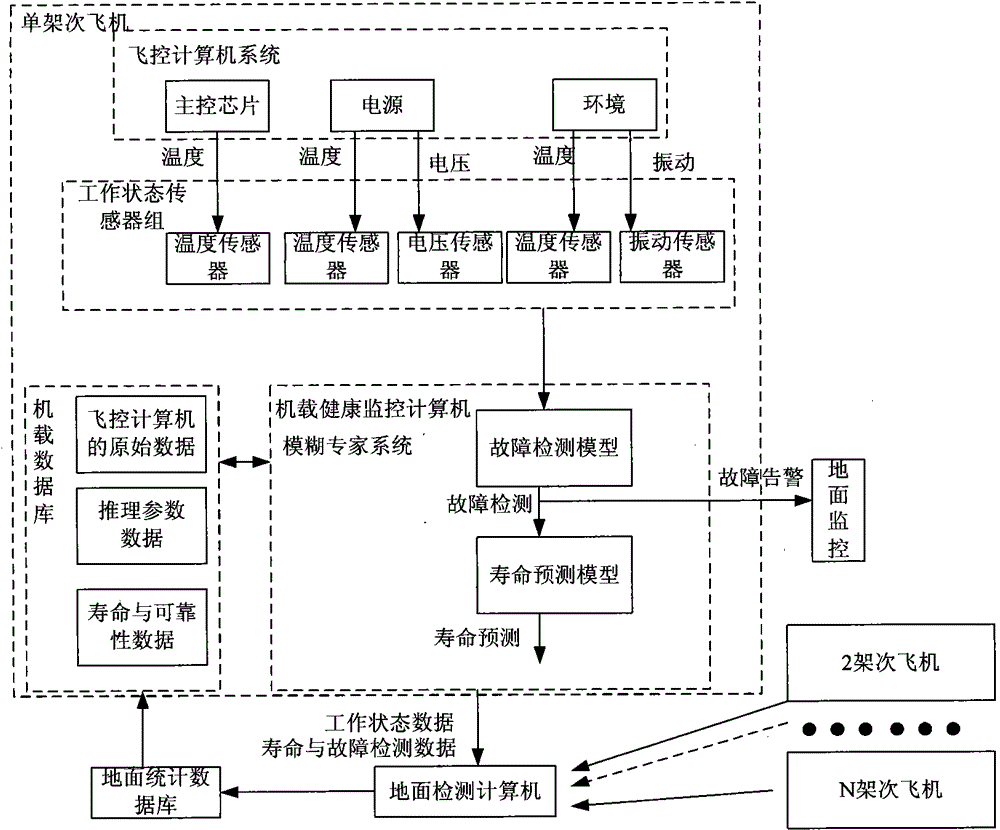

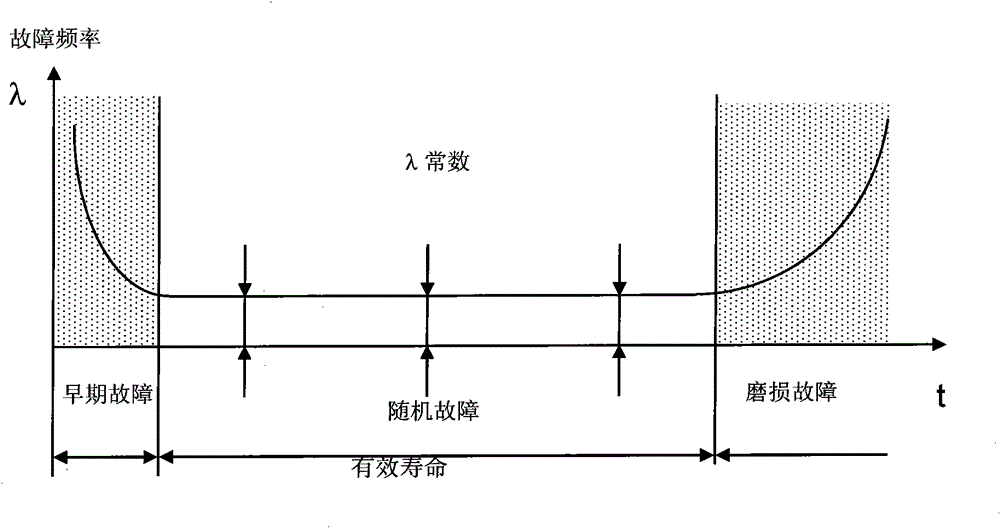

[0061] A fuzzy inference method is designed for predicting failure modes based on sensor inputs of operating conditions. The functional block diagram of the life prediction system implementation is as follows: figure 2 shown. This method introduces two kinds of databases, ground and airborne, which contain inspection information for probabilistic analysis of sensor inputs, multiple sets of flight control computer system parameters and long-term statistical data, and introduces fuzzy rules to compare sensor inputs with expected consequences related.

[0062] Life prediction software workflow such as Figure 4 shown. For the detection data of the sensor group, firstly, according to the statistical parameters stored in the database, the input quantity is fuzzy, as shown in Table 1, and then the abnormal threshold is judged. If the threshold value is exceeded, the corresponding overrun flag is set, otherwise it is not set. Then according to the knowledge base rules of the ex...

Embodiment 2

[0072] For use with customized flight control computer systems. The life prediction system utilizes the existing software and hardware resources of the flight control computer, the main program is stored and run in the flight control computer, and the flight control computer starts to work with it. After the flight control computer is turned on, the sensor group is used to monitor the temperature, voltage, environmental vibration and other working status data of the chip, power supply and other links, and compressed and stored in the flight control computer system. After each flight mission is completed and returned to the field, the data is downloaded to the ground detection computer for comprehensive statistical analysis.

[0073] Among them, there are two tables in the database, one is the public data table, and the other is the data status table of each set, as shown in Table 2 and Table 3 respectively:

[0074] Table 2 Common Data Table Properties

[0075] data...

Embodiment 3

[0104]It is installed and used on small batches of flight control computers. Without changing and occupying the software and hardware resources of the original flight control system, the life prediction system software is installed on an independent airborne detection computer, and the sensor group is installed on the surface of the main chip of the flight control computer and the power interface. During the working process, the sensor group collects the working status data of the flight control computer, and the life prediction system evaluates the working status and performs fault monitoring. After the flight mission is completed and returned to the field, the data will be downloaded to the ground detection computer. The ground detection computer conducts statistical analysis on this sortie and the working status of the flight control computer of multiple aircraft of the same model. The results of the analysis are fed back to the logistics maintenance personnel.

[0105] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com