Device for controlling coal mill

A crushing device and control device technology, applied in the direction of combustion control, control system, block/powder supply/distribution, etc., can solve problems such as difficult boiler operation, HGI and moisture content deviation, and inability to perform stable control, etc., to achieve Stabilization corresponds to the effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

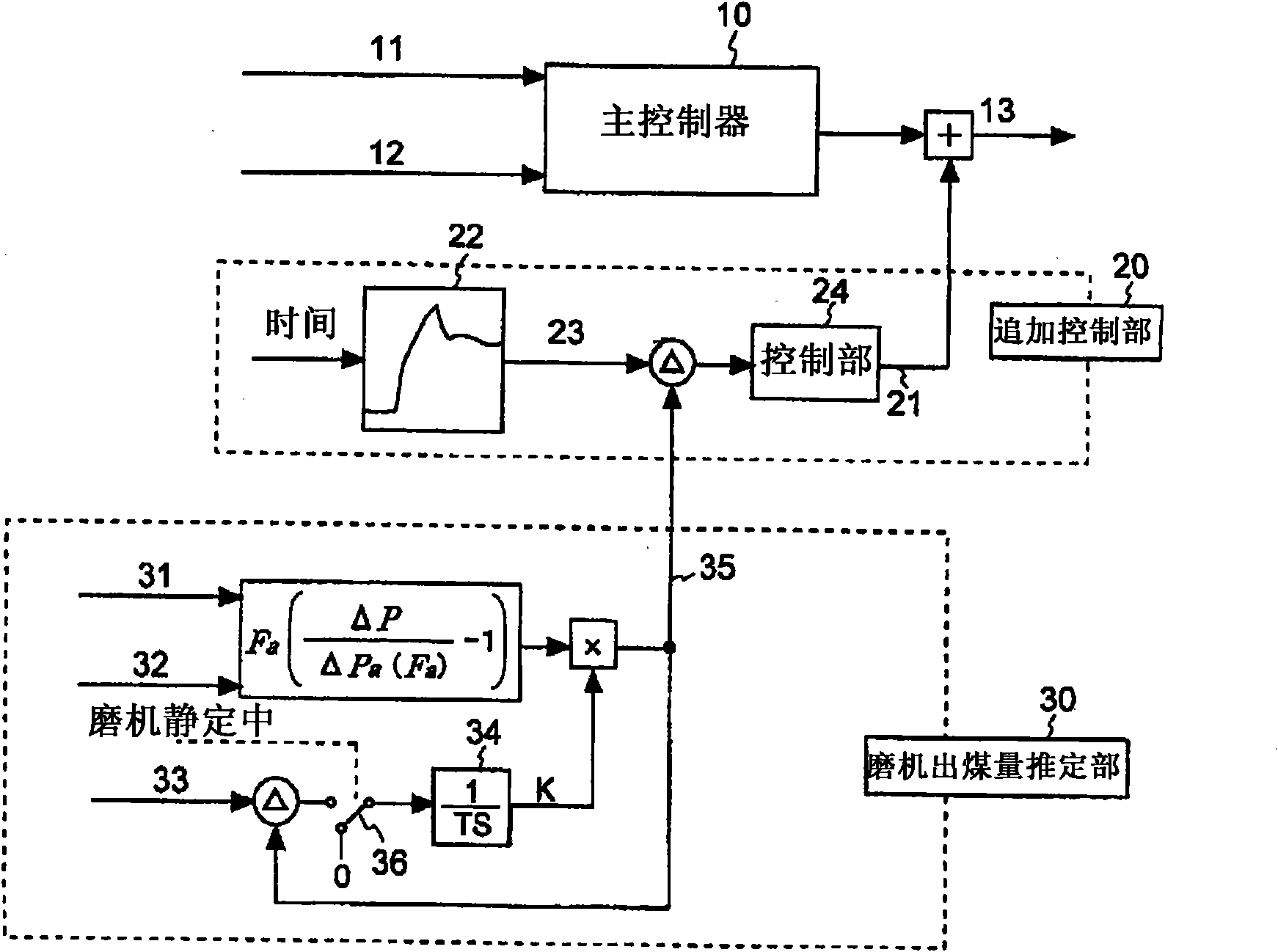

[0041] figure 1 It is a block diagram showing the configuration of the control device according to the first embodiment of the present invention. The invention adds the output signal of the control system using the deviation between the standard mill coal output pattern and the currently running mill coal output pattern as a correction signal to the basic signal of the existing control system, thereby For more stable mill coal output control, the configuration of the first embodiment is to use the command value of the coal feed amount as the command signal related to the coal feed amount.

[0042] figure 1 Among them, the control device of the first embodiment is composed of a main controller 10 which is an existing control system, an additional control unit 20 , and a mill coal output estimation unit 30 .

[0043] The mill coal output estimating unit 30 measures the mill furnace differential pressure (ΔP) 31 and the air flow rate (Fa) 32 which are original detection points,...

no. 2 approach

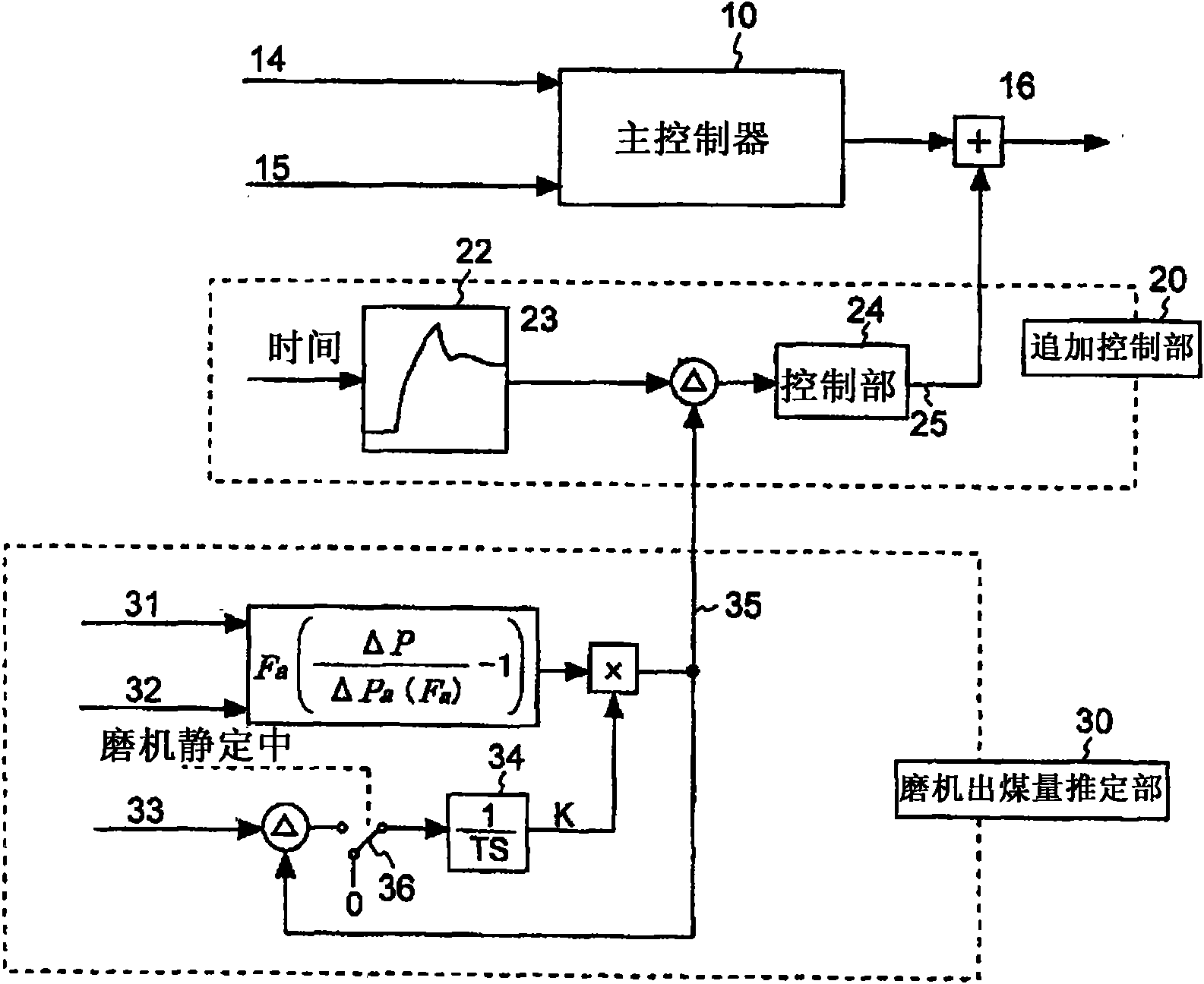

[0056] figure 2 It is a block diagram showing the configuration of the control device according to the second embodiment of the present invention.

[0057] In the second embodiment, it is configured to use the MRS rotational speed of the coal crushing device as the command signal related to the amount of coal fed.

[0058] figure 2 Among them, the control device of the second embodiment is constituted by a main controller 10 as an existing control system, an additional control unit 20 , and a mill coal output estimation unit 30 .

[0059] The mill coal output estimation unit 30 and the additional control unit 20 are the same as those in the first embodiment.

[0060] A mill coal feed rate command 14 and a mill current 15 are input to the main controller 10, and arithmetic processing is performed based on these to obtain an MRS rotational speed command value 16. At this time, the MRS rotational speed command correction value 25 obtained by the mill coal output estimation u...

no. 3 approach

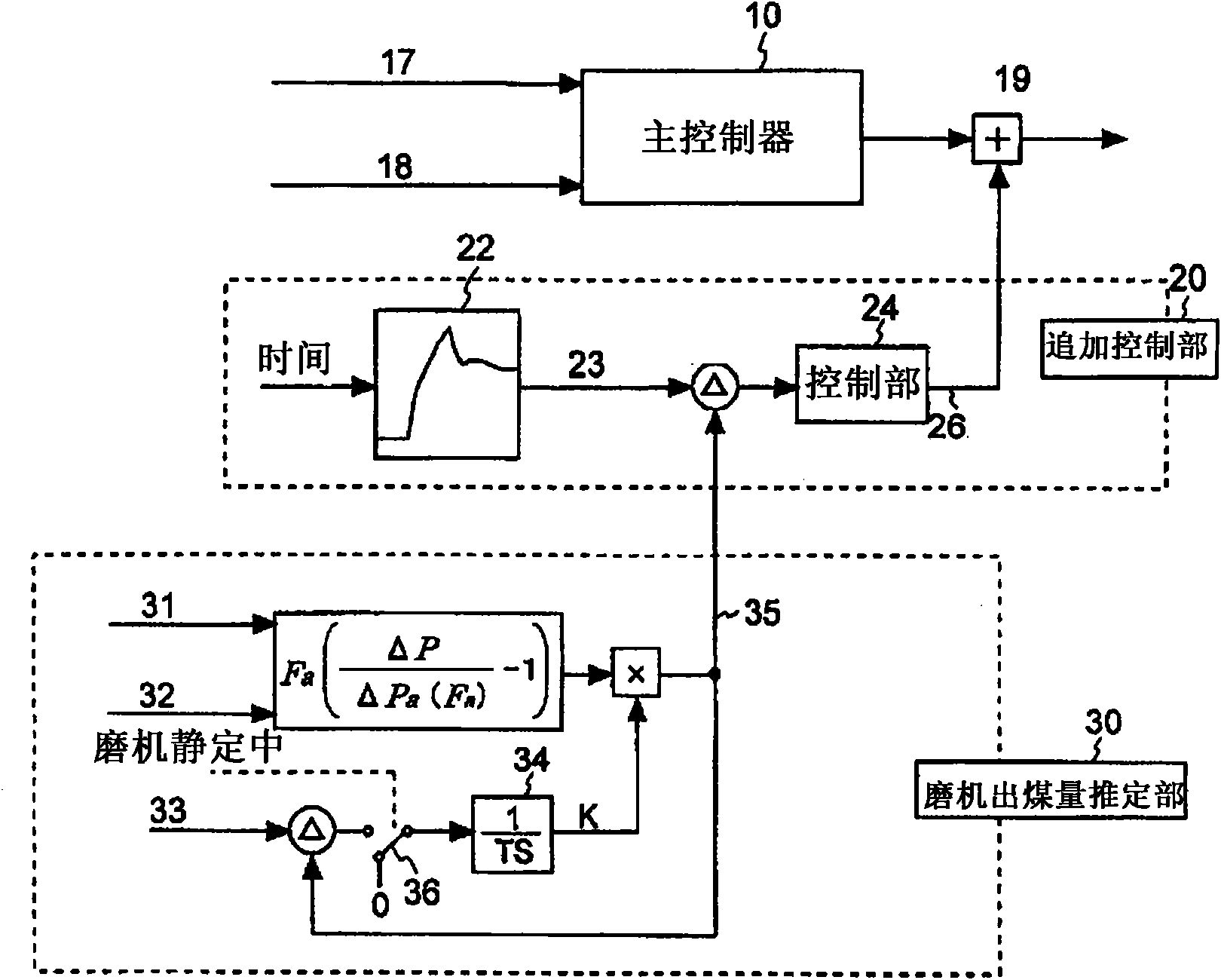

[0063] image 3 It is a block diagram showing the configuration of a control device according to a third embodiment of the present invention.

[0064] In the third embodiment, it is configured to use the load pressure of the hydraulic load device included in the coal crushing device as the command signal related to the coal feed amount. The so-called load pressure means the pressure applied to the rollers in the coal pulverizing device.

[0065] exist image 3 Among them, the control device of the third embodiment is constituted by a main controller 10 as an existing control system, an additional control unit 20 , and a mill coal output estimation unit 30 .

[0066] The mill coal output estimation unit 30 and the additional control unit 20 are the same as those in the first embodiment.

[0067] The mill coal feed command 17 and the roller lift 18 are input to the above-mentioned main controller 10, and calculation processing is performed based on these, and the pressure set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com