Method for fast measuring imprinting effect of ferroelectric film

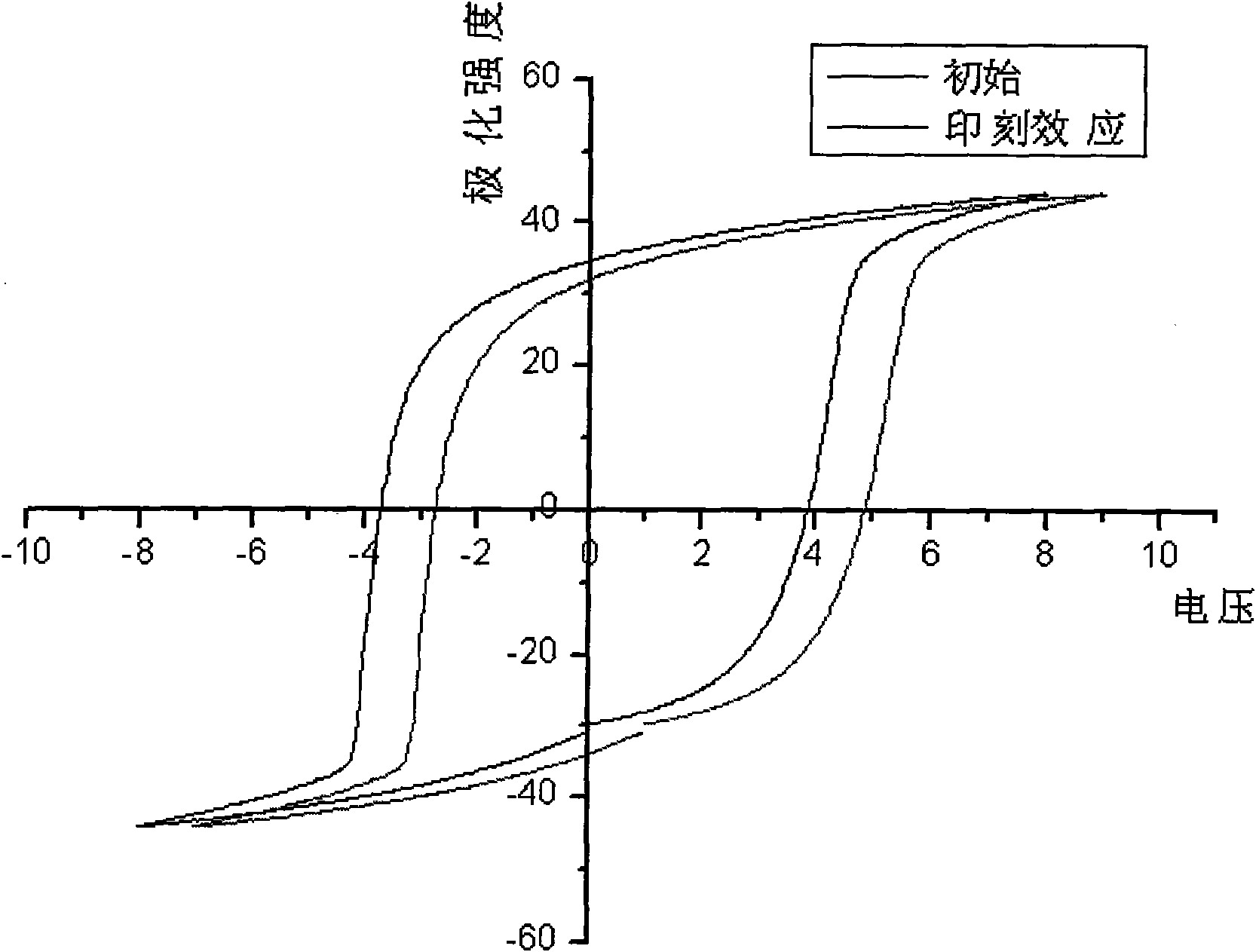

A ferroelectric thin film and effect technology, applied in the field of microelectronics, can solve problems such as read and write operation voltage failure, remanent polarization value becomes smaller, and data retention characteristics become worse, achieving good application prospects and reducing time effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1. Measuring the imprinting effect produced by adding an imprinting voltage of a certain time and a certain size

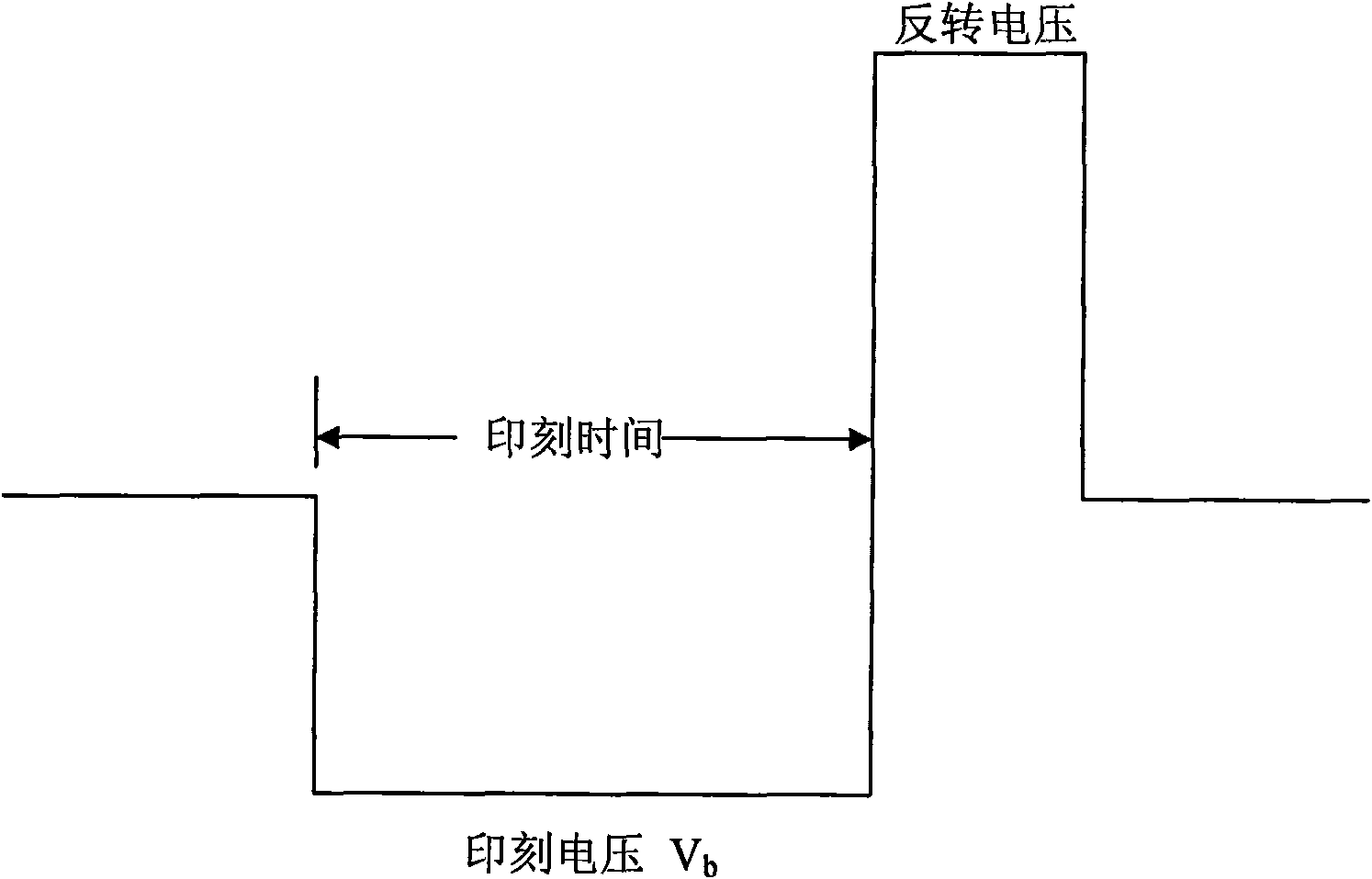

[0027] Use the signal generator to edit a bias voltage V that can make the ferroelectric film produce imprinting effect b , the size should satisfy |V b |>|V C |, the range of time t can be from the order of nanoseconds to the order of seconds. at V b Immediately after the end, add a reverse voltage in the opposite direction (V SW ), the pulse time is about tens of nanoseconds, and the size should satisfy |V SW |>|V b |, which reverses the domain polarization to generate a polarization reversal current. Finally, use an oscilloscope to read the load voltage (V L =I SW × R L ). According to the formula of reverse current

[0028]

[0029] Launch V C =V SW -I SW × R L =V SW -V L , so that V C value. The test pulse waveform is as image 3 shown.

[0030] Describe below in conjunction with specific example, the ferroelectric fi...

Embodiment 2

[0034] Measuring the imprinting effect after applying a preset bias voltage and then waiting for a period of time after a reverse pulse

[0035] Different from the imprinting effect produced by adding an imprinting voltage of a certain size and time, the pulse waveform applied in the test is as follows: Figure 7 As shown in , first apply a positive voltage pulse V presetting As a preset voltage, its magnitude should satisfy |V presetting |>|V C|, the pulse time is tens of nanoseconds, and the function of the preset voltage is to make the electric domain of the ferroelectric film turn to one direction first. After adding the preset voltage, in order to keep the injected charge in a stable equilibrium state, it is necessary to wait for a relaxation time t rel , the length of time is t rel =5s+20t, where t is the time interval between two positive and negative bipolar pulses applied later to test the imprinting effect. stay in t rel Finally, add a positive and negative bip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com