Long telescopic soot blower

A soot blower, long telescopic technology, applied in the direction of combustion product treatment, combustion method, removal of solid residue, etc., can solve the problems of non-adjustable pressure, imprecise cooperation between valve disc and valve seat, and easy leakage, etc., to achieve Avoid dead ends, reduce compression-rebound degree, and prevent leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

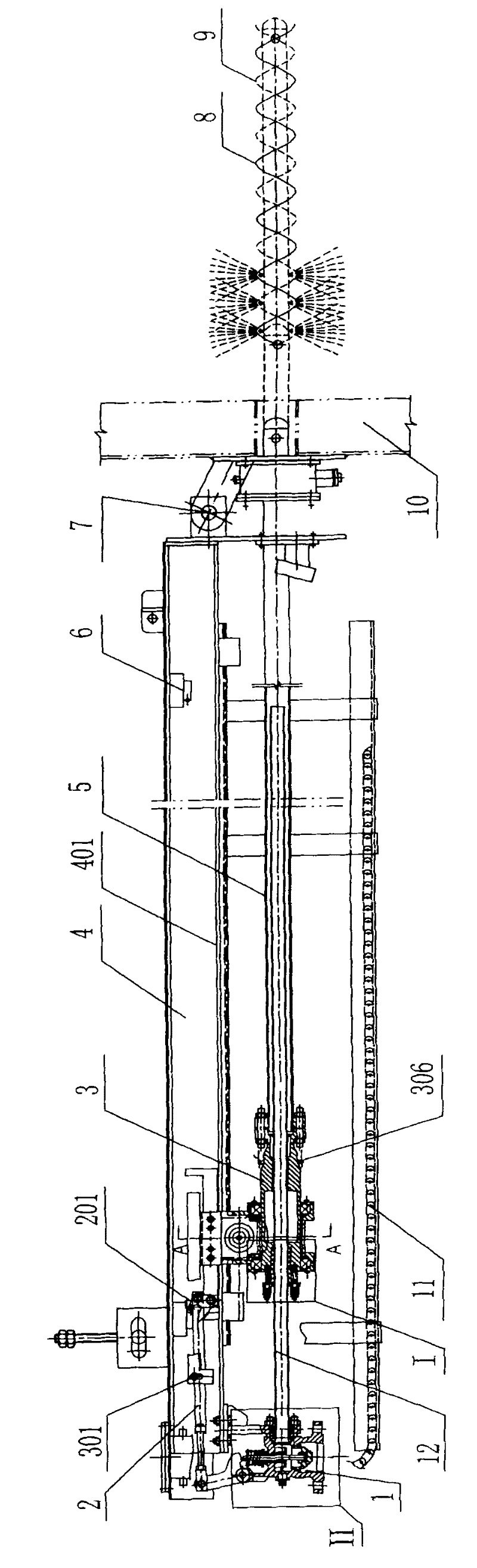

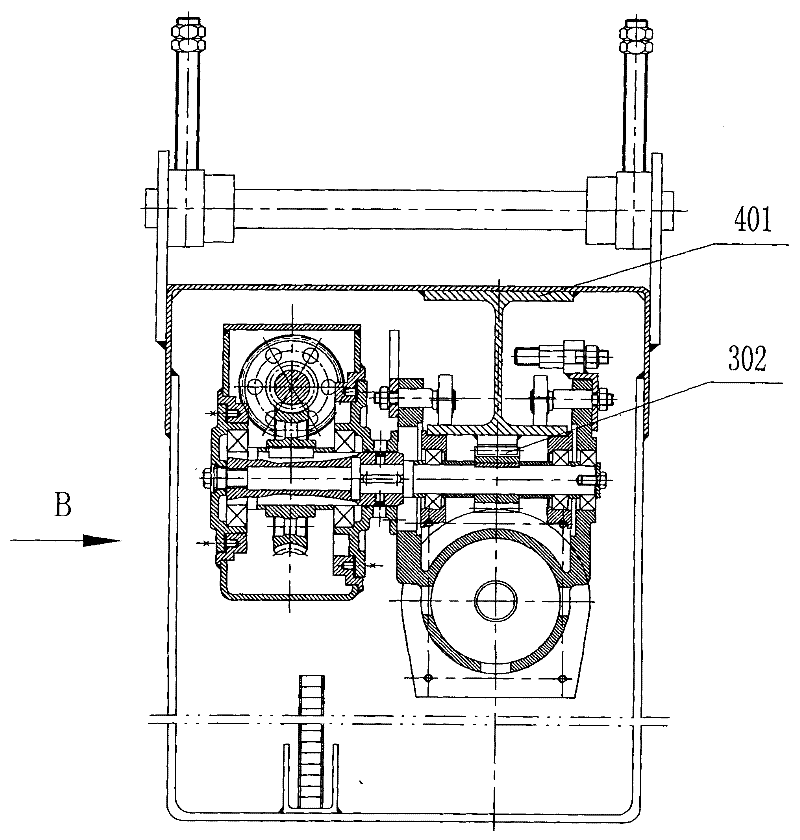

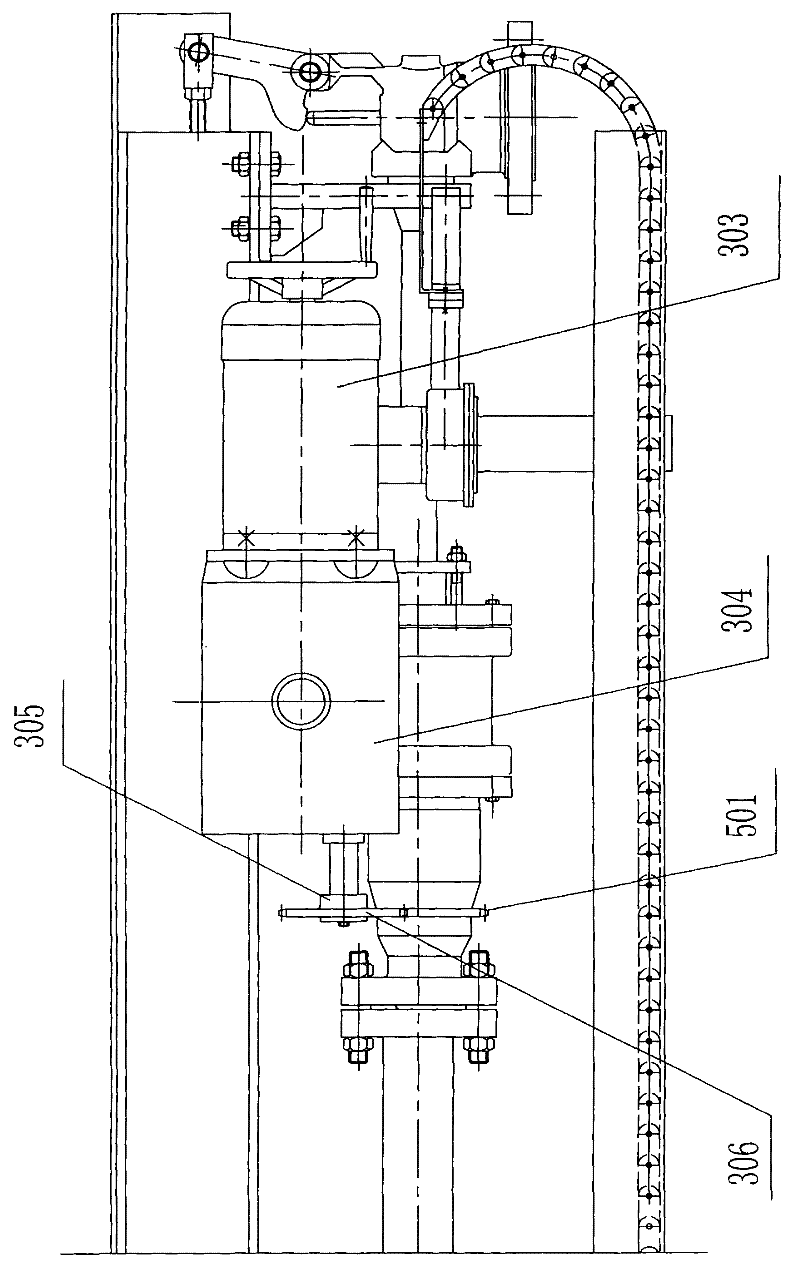

[0037] see Figure 1~3 , figure 1 It is a schematic diagram of the front structure of the long telescopic soot blower of the present invention. figure 2 for figure 1 A-A cut-away diagram. image 3 for figure 2 B direction view. Depend on figure 1 , figure 2 and image 3 It can be seen that the long telescopic sootblower of the present invention includes a box body 4, a guide rail 401 is arranged horizontally on the upper part of the box body 4, and a sports car 3 is arranged on the guide rail 401. The sports car 3 includes a motor 303 and a double output shaft reducer 304, The double output shaft reducer 304 has an input shaft and two output shafts, one output shaft is connected with the guide rail 401 through a rack and pinion pair 302, and drives the sports car 3 to reciprocate along the guide rail 401, and the other output shaft is installed There is a main drive disc 305 and a speed reducer sprocket 306, such as Figure 4 and Figure 5 , the main transmission ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com