Operating platform for trenchless inversion liner of buried pipeline

A technology of buried pipeline and operating platform, which is applied in the direction of pipe components, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problem of lack of perfect operating platform, and achieve the effect of compact structure, perfect function and guarantee of integrity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

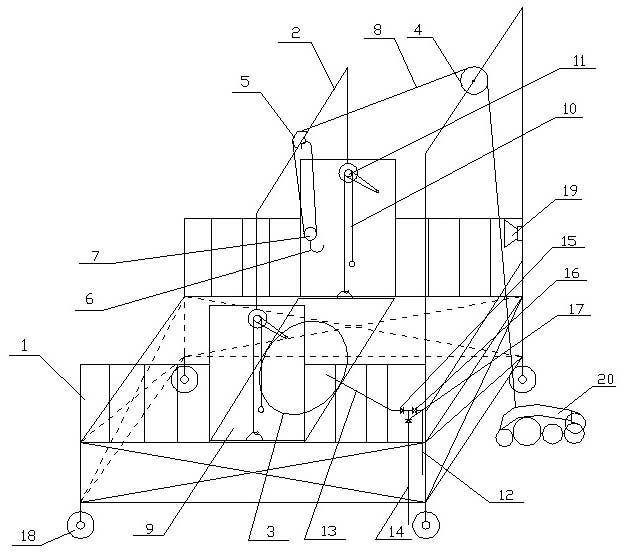

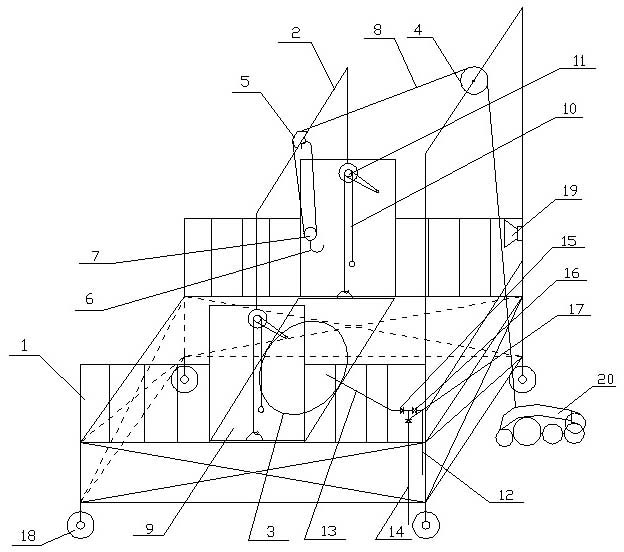

[0017] As shown in the figure, the operation platform for the non-excavation flipping lining of buried pipelines according to the present invention includes a platform frame body 1 with a frame structure, and a door-shaped hoisting navigator extending upwards along the middle of the platform frame body 1 2. A hoisting device controlled by a power source 20 is provided on the hoisting navigator 2; a lining introduction cylinder 3 is arranged longitudinally below the hoisting navigator 2, and the inner lining introduction cylinder 3 is connected with the hoisting device The platform frame bodies 1 are connected.

[0018] The lifting device is fixed pulleys 4, 5 respectively arranged on the platform frame body 1 and the hoisting navigator 2, and a movable pulley 7 with a hook 6, and the steel wire rope 8 controlled by the power source 20 is wound around the platform frame in turn. Body fixed pulley 4, lifting navigator fixed pulley 5 and movable pulley 7 are fixed on the suspensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com