Cycloid planetary speed reducer of rapid point machine

A kind of needle pendulum planetary deceleration, switch machine technology, applied in mechanical equipment, gear transmission, belt/chain/gear and other directions, can solve the problems of weak strength and rigidity, complex structure, large volume, etc., to improve the strength and rigidity , The effect of large transmission ratio range and high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

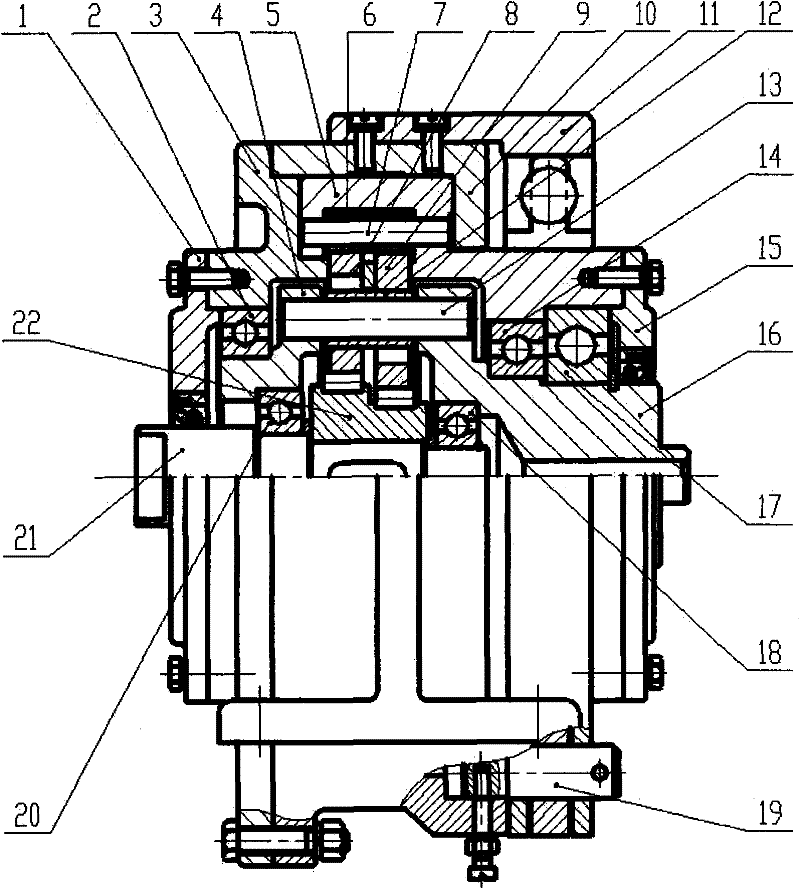

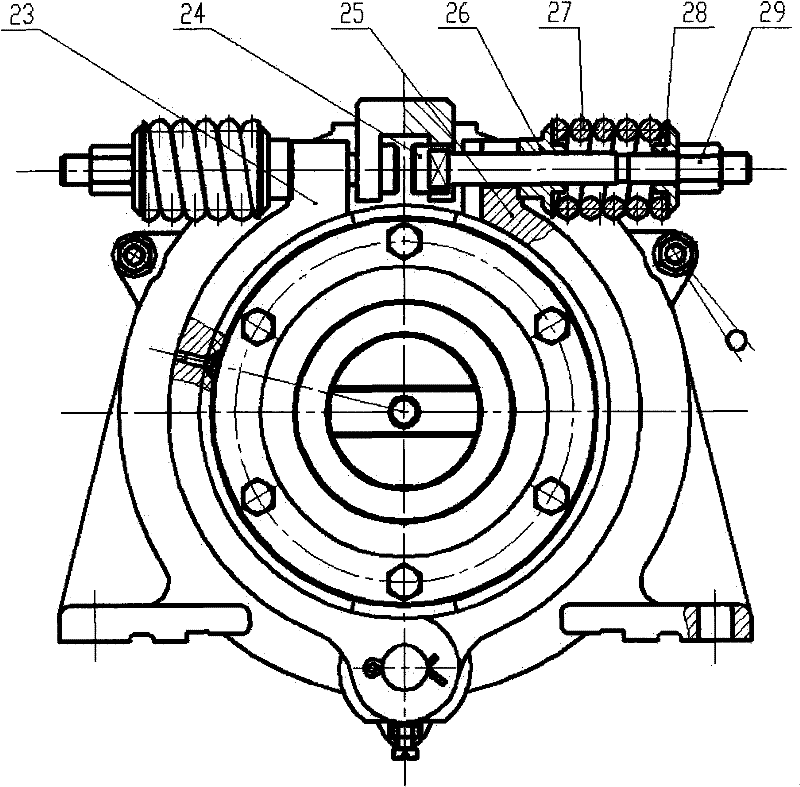

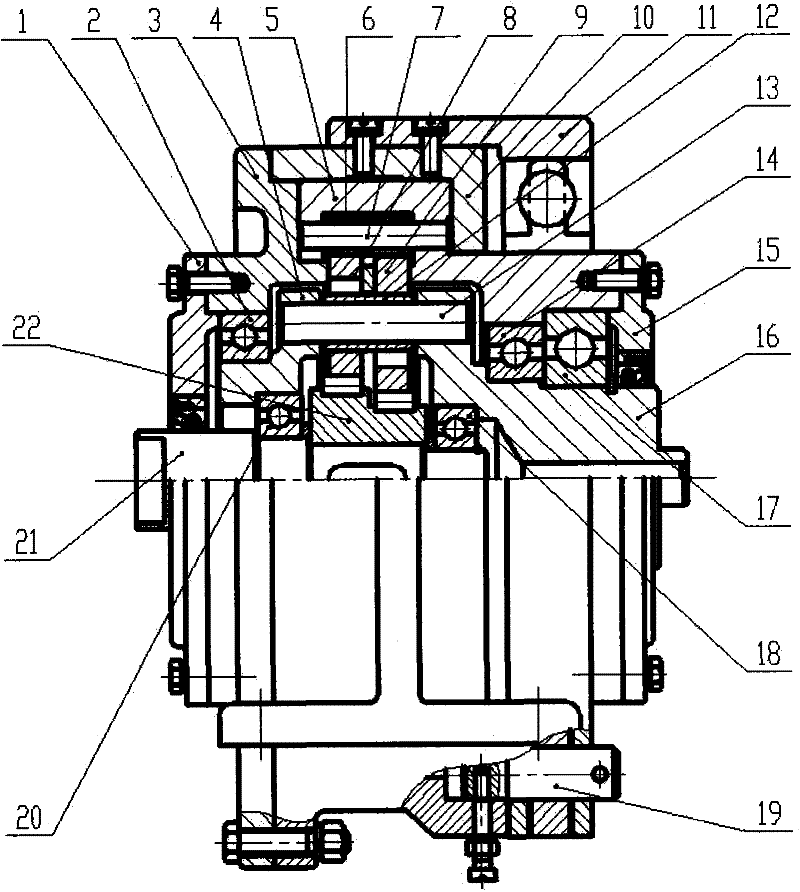

[0012] The pin pendulum planetary reducer for fast switch machines proposed by the present invention consists of left and right glands 1, 15, an equal load disc support bearing 2, an end cover 3, an equal load disc 4, a pin gear housing 5, and a pin gear sleeve 6 , pin tooth pin 7, left and right cycloidal wheels 8, 9, casing 10, fixed frame 11, column pin sleeve 12, column pin 13, output shaft support bearing 14, 17, output shaft 16, input shaft support bearing 18 , 20, splint shaft 19, input shaft 21, double eccentric bearing 22, left and right splints 25, 23, bolts 24, support pads 26, springs 27, spring pads 28 and thickened nuts 29, are characterized in that, evenly loaded The disc 4 is supported on the casing end cover 3 through the disc support bearing 2, and the output shaft 16 is supported by the two ends of the output shaft support bearings 14 and 17. The outer diameters of the output shaft support bearings 14 and 17 are different, so that the output mechanism axially...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com