Continuous cyclic drilling device

A technology for drilling and drilling pipes, which is applied in the field of drilling equipment, which can solve the problems of reduced clamping force of drill pipes, damage to the drill pipe body, inability to remove and buckle, etc., so as to improve the stress state, save drilling costs, and reduce drilling accidents Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

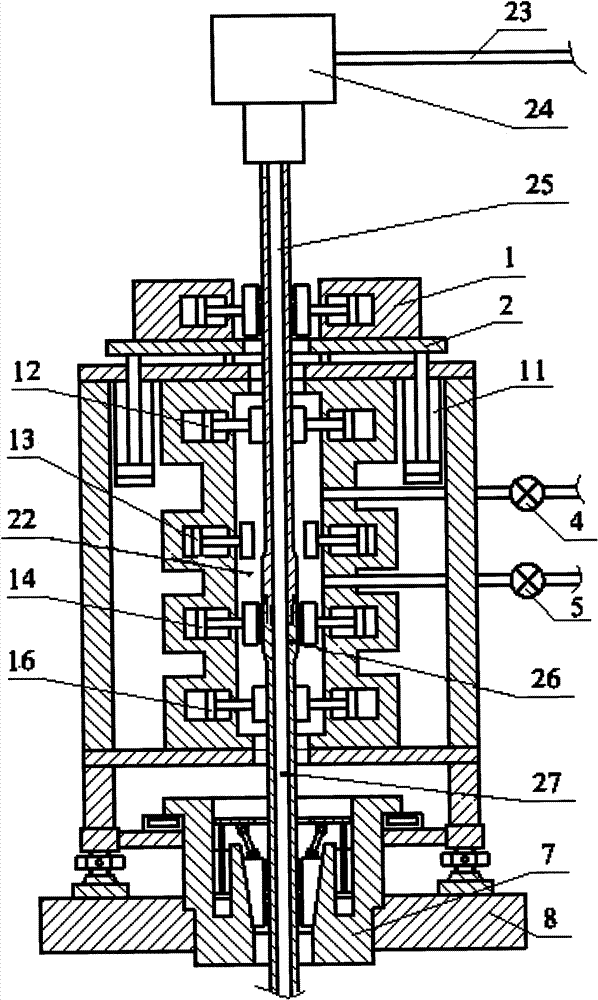

[0026] Embodiment 1: Taking an uninterrupted circulation drilling device as an example, the present invention will be further described in detail.

[0027] refer to figure 1 . The uninterrupted circulation drilling device mainly consists of a drill pipe power tong 1, a power tong base plate 2, a balance compensation cylinder 11, a chamber assembly 3, an upper chamber bypass valve 4, a lower chamber bypass valve 5, a bracket assembly 6 and drilling The power slip consists of 7 components.

[0028] The drill pipe power tong 1 is fixed on the power tong bottom plate 2 at the top of the balance compensation cylinder 11 . The balance compensation oil cylinder 11 is a double-acting single-piston rod hydraulic oil cylinder. Balance compensation oil cylinder 11 is vertically fixed below the upper connecting plate 10 of support assembly 6, namely balance compensation oil cylinder 11 has four, and the tops of the piston rods of four balance compensation oil cylinders 11 are symmetri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com