Transmission unit for coke pushing machine

A technology of transmission device and coke pusher, which is applied in the direction of transmission device, gear transmission device, mechanical equipment, etc., which can solve the problems of large space occupied by the whole machine, damage of coke pusher, poor bearing capacity, etc., to achieve reliable operation and reduce installation The effect of space and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with drawings and embodiments.

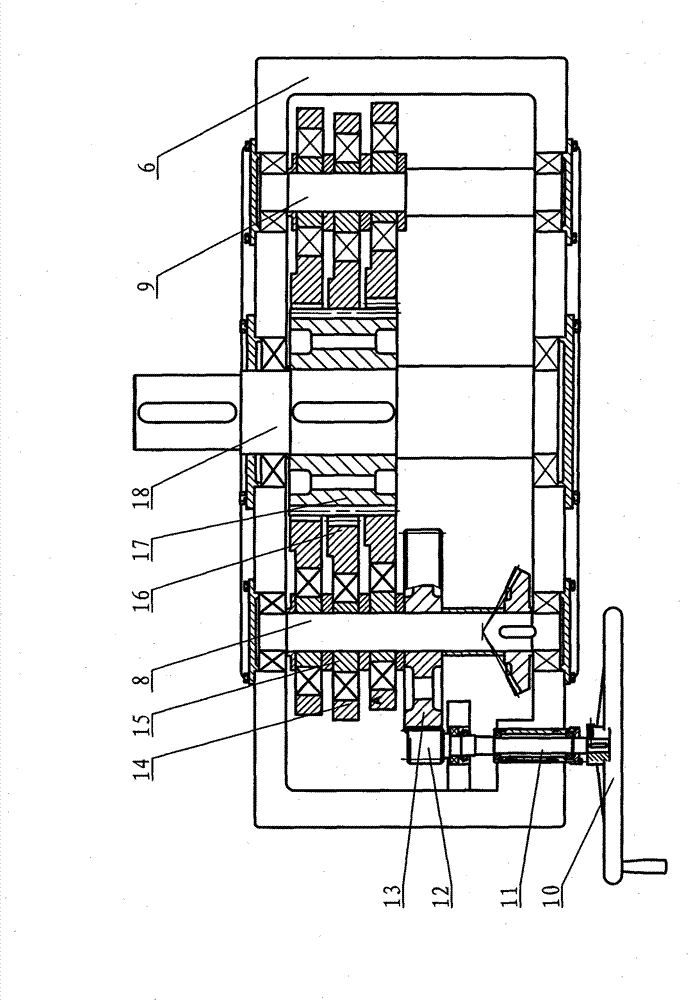

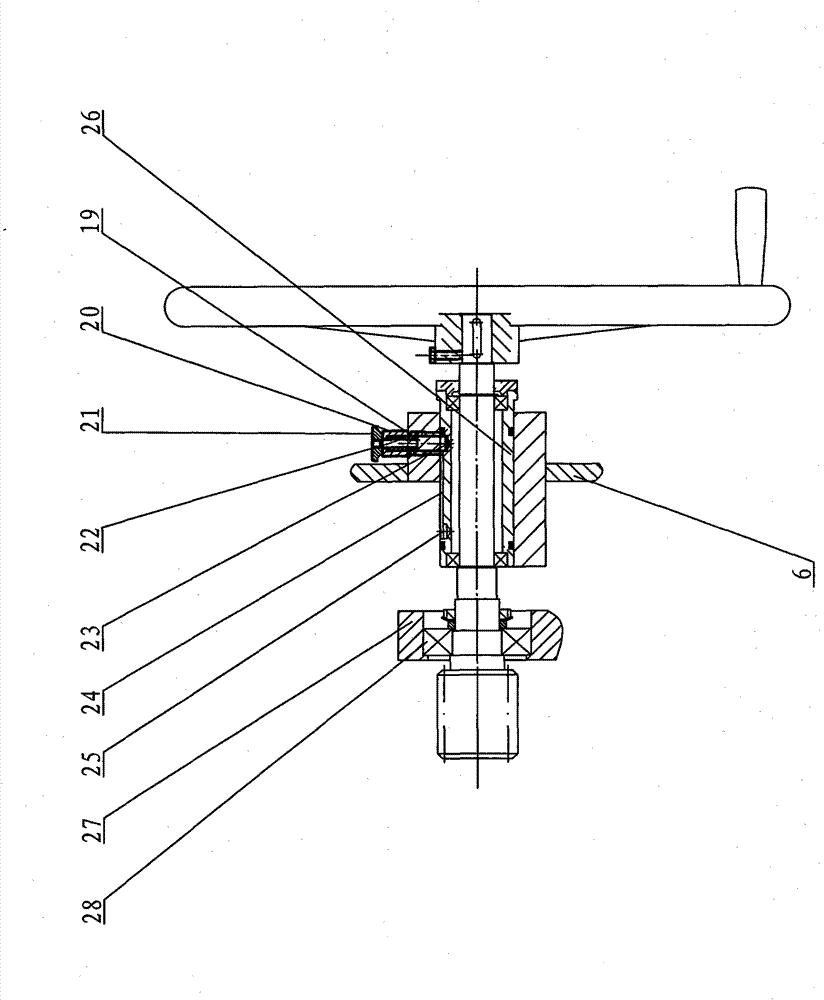

[0016] Figure 1-3 As shown, a transmission device for a coke pusher mainly includes a motor 1, a main input shaft 4, a small bevel gear 5, a box body 6, a large bevel gear 7, a main drive shaft 8, an auxiliary drive shaft 9, a hand wheel 10, an auxiliary Input shaft 11 , pinion gear 12 , bull gear 13 , transmission ring plate 14 , internal gear 16 , external gear 17 and output shaft 18 . The motor 1 is vertically installed above the box body 6 through the flange 2, the output shaft of the motor is connected to the upper end of the main input shaft 4 through the coupling 3, the lower end of the main input shaft 4 is provided with a small bevel gear 5, and the small bevel gear 5 is connected to the box body 6 The large bevel gear 7 on the main drive shaft 8 inside is meshed for transmission, and the output shaft of the motor is perpendicular to the main drive shaft; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com