Stone-plastic simulated wood floor and manufacturing method thereof

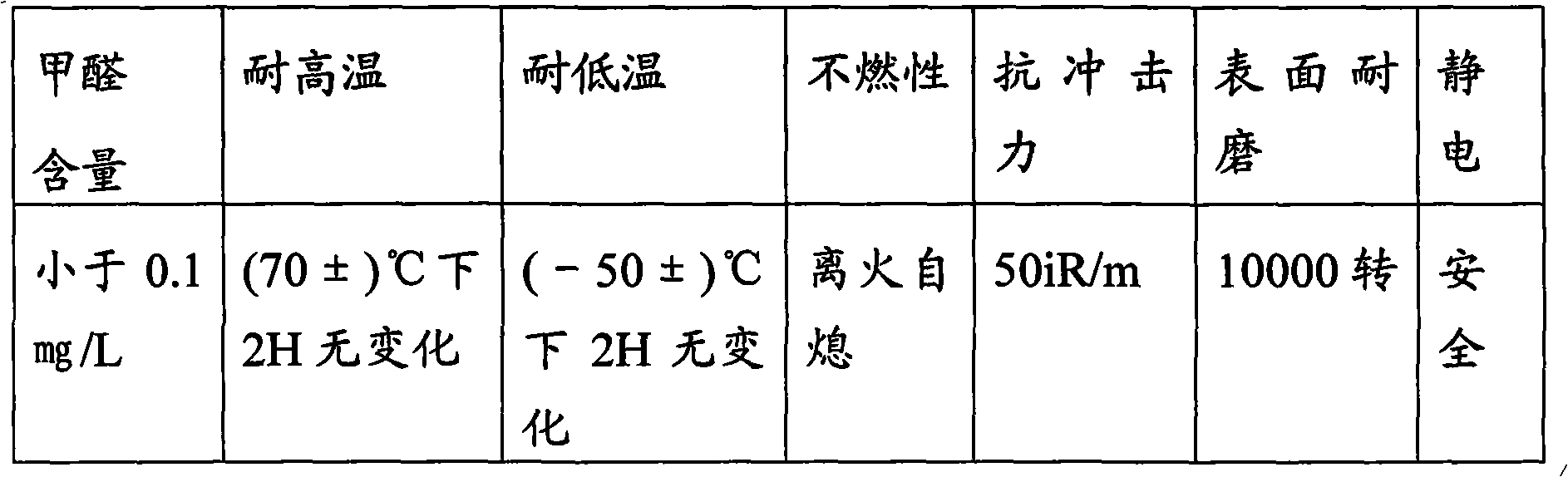

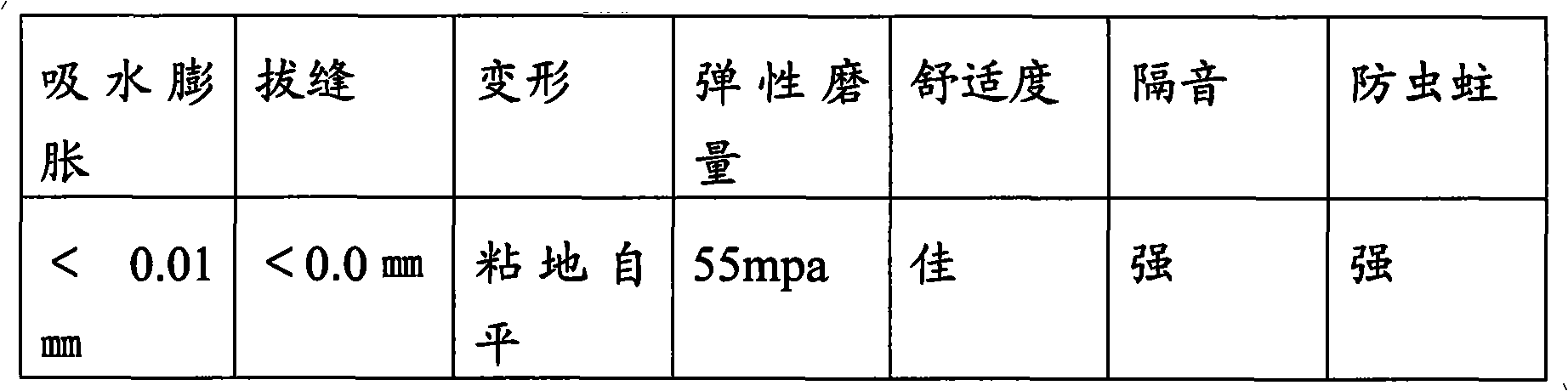

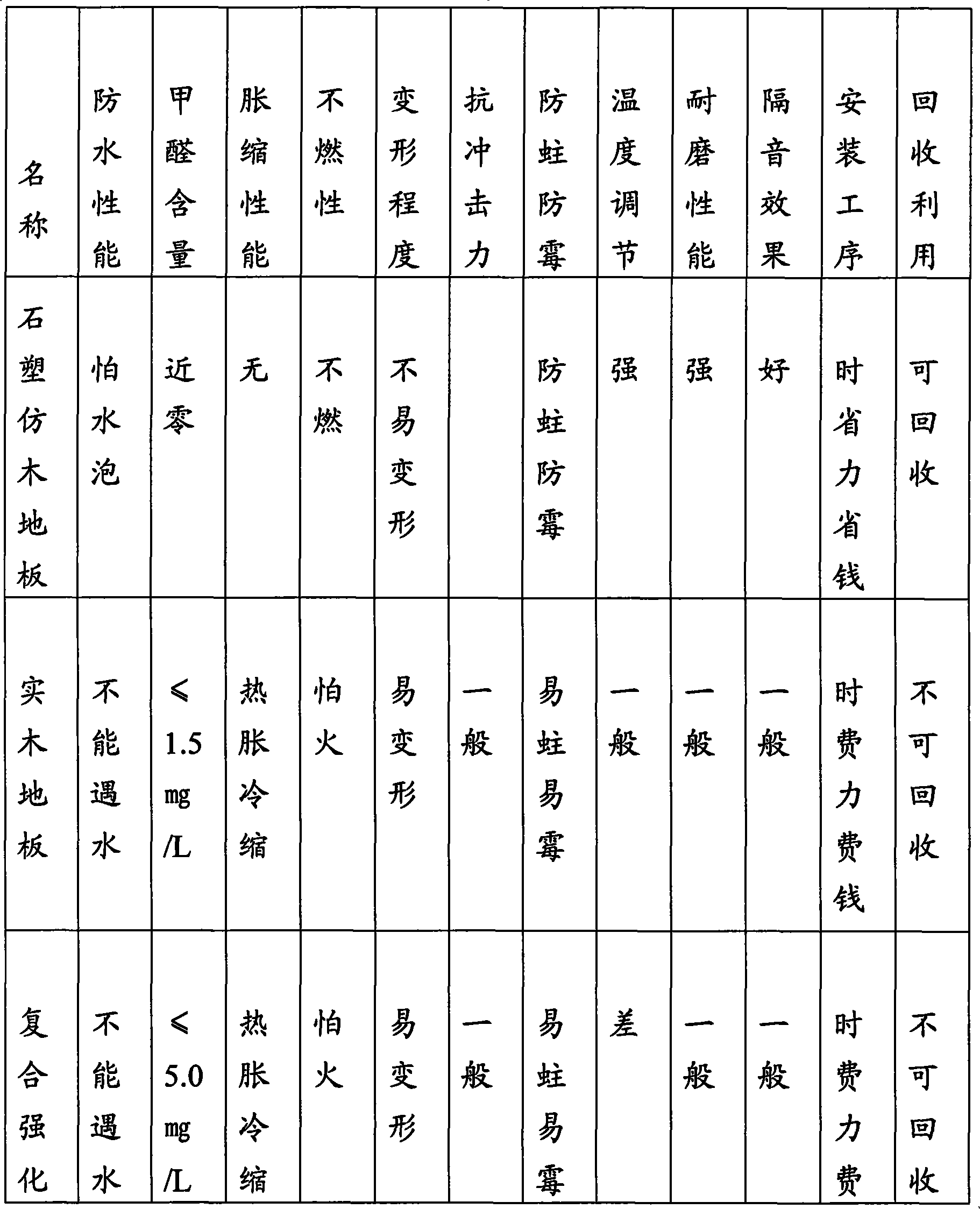

A technology of imitating wood floor and stone plastic, applied in the direction of building, building structure, floor, etc., can solve the problems of not easy to slip, the floor is afraid of fire, etc., to achieve the effect of not easy to slip and save resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] According to the mass percentage, the stone-plastic imitation wood floor includes: 60% calcium carbonate ore powder or tailings slag powder, 36% waste PVC pellets, 0.5% polyamino modified silicone oil, 0.4% polyether silicone oil, and 0.4% dibutyl fat , Paraffin 0.5%. , Composite stabilizer 0.4%, tribasic lead sulfate 0.4%. , 0.5% lead stearate, 0.5% barium stearate and 0.4% stearic acid.

Embodiment 2

[0018] According to the mass percentage, the stone-plastic imitation wood floor includes: 70% calcium carbonate ore powder or tailings slag powder, 24.9% waste PVC pellets, 1.0% polyamino modified silicone oil, 0.8% polyether silicone oil, and 0.6% dibutyl fat , paraffin 0.5%, compound stabilizer 0.2%, tribasic lead sulfate 0.6%, lead stearate 0.4%, barium stearate 0.4% and stearic acid 0.6%.

[0019] Embodiment two:

[0020] According to the mass percentage, the stone-plastic imitation wood floor includes: 30% calcium carbonate ore powder or tailings slag powder, 68% waste PVC pellets, 0.2% polyamino modified silicone oil, 0.2% polyether silicone oil, and 0.2% dibutyl fat , paraffin 0.2%, compound stabilizer 0.2%, tribasic lead sulfate 0.2%, lead stearate 0.2%, barium stearate 0.4% and stearic acid 0.2%.

[0021] The embodiment of the present invention also provides a processing method of stone-plastic imitation wood floor, comprising the steps of:

[0022] A. Weigh the raw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com