Portable gas brazing welding gun

A brazing, portable technology, used in welding equipment, electric heating devices, metal processing equipment, etc., can solve problems such as complex structure, and achieve the effect of ensuring safety, eliminating safety accidents, and eliminating fear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

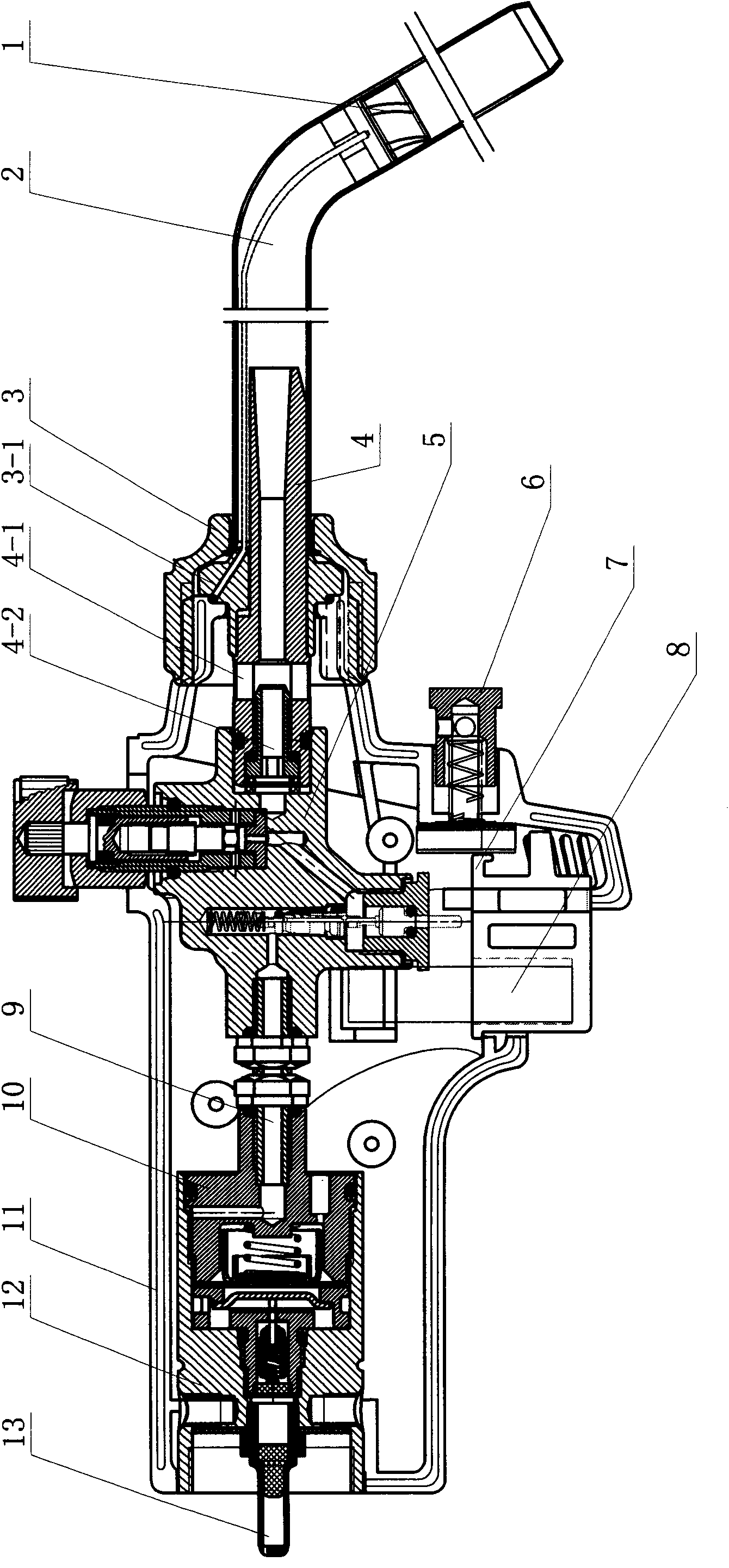

[0016] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0017] There are four evenly distributed through-holes with a chamfer of 120° on the middle periphery of the air mixer 4. The diameter of the through-holes is Φ5-Φ6mm and communicates with each other. It communicates with the outside world, so that the outside air can smoothly enter and mix with the gas.

[0018] There is a through hole in the middle, an opening at one end, and a nozzle 4-2 with a spray hole on the bottom surface of the other end, which is installed in the through hole at one end of the air mixer 4 with a sealing ring, and one end of the air mixer 4 is installed in the regulating valve body 5-1 in the threaded hole at the right end, and set multiple seals.

[0019] The middle of the other end of the air mixer 4 is a bell mouth to facilitate the entry and exit of air and gas. The threaded connection gun barrel assembly 3 at 11 ports fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com