Roller coating device and roller coating method

A rolling coating and storage technology, which is applied in the direction of surface coating liquid devices, coatings, pretreatment surfaces, etc., can solve the problem of difficulty in forming a uniform thickness, easy adhesion of treated objects, and adhesion of coating treatment agents Uneven volume and other problems to achieve the effect of preventing mutual adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

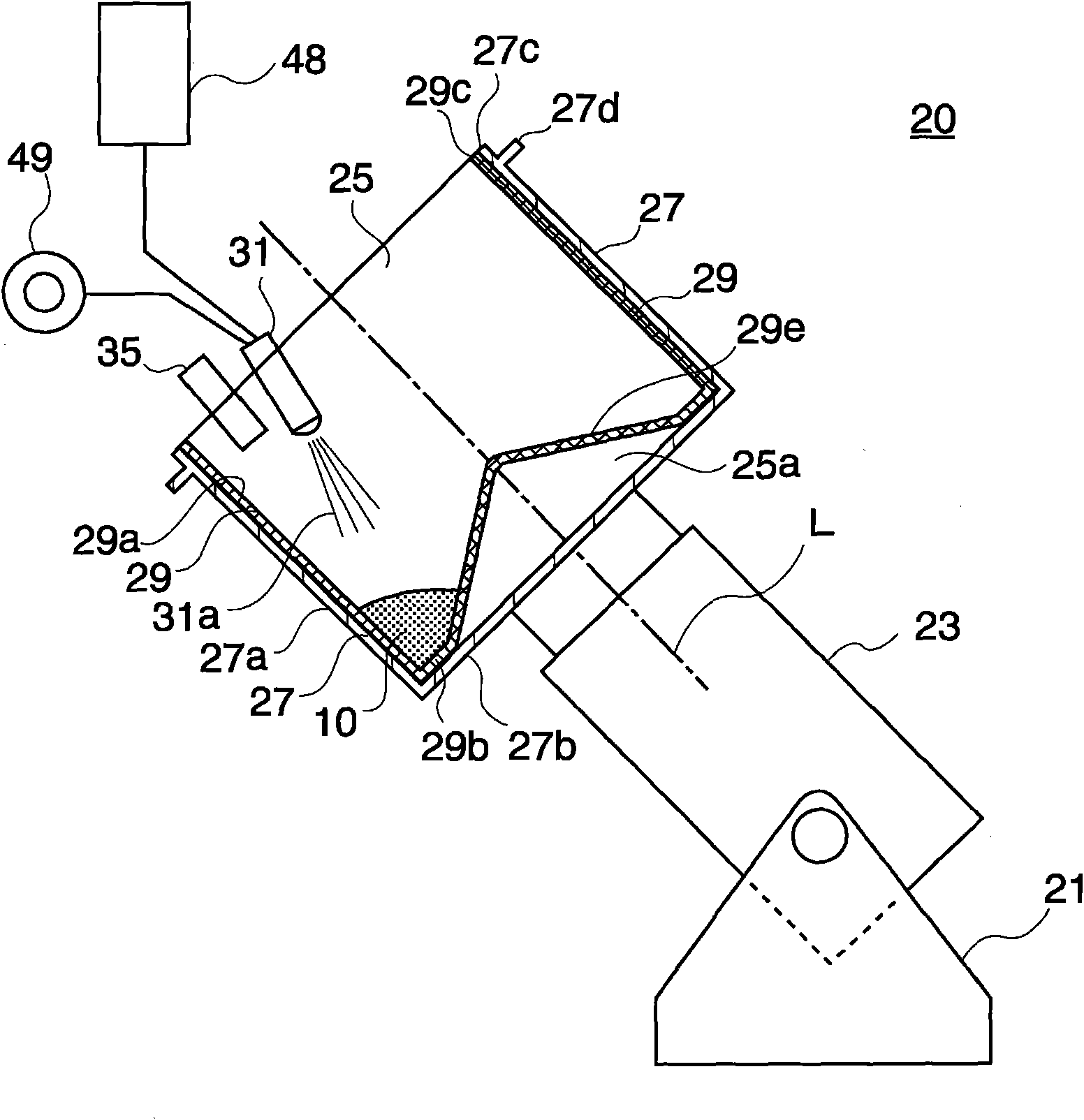

[0043] The first embodiment is as figure 1 with figure 2 As illustrated: it is characterized in that,

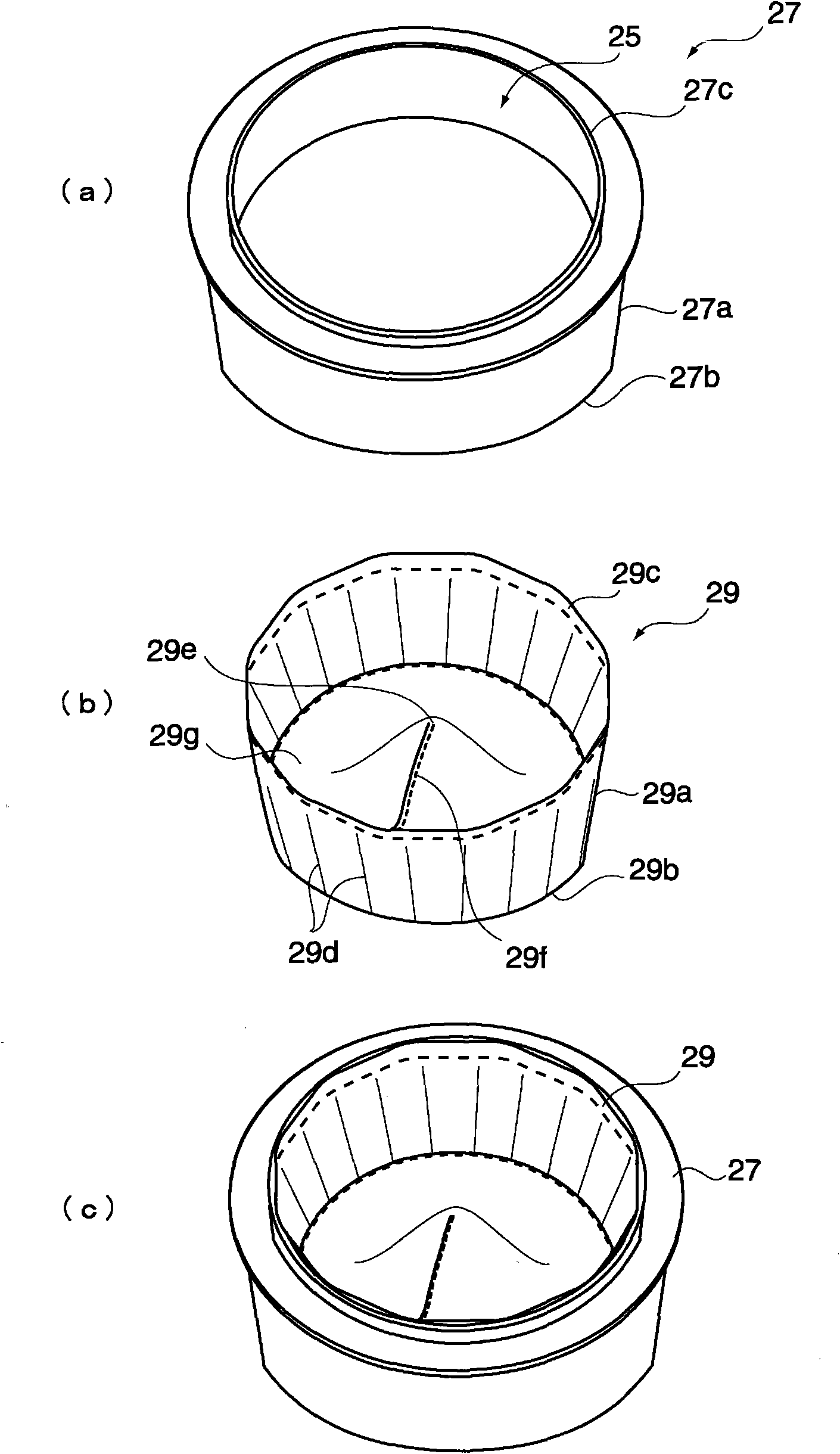

[0044] The roll coating device 20 is provided with: a rotating unit 27, which has an accommodating space 25 and rotates around a rotating shaft (L) inclined at a predetermined angle relative to the horizontal direction;

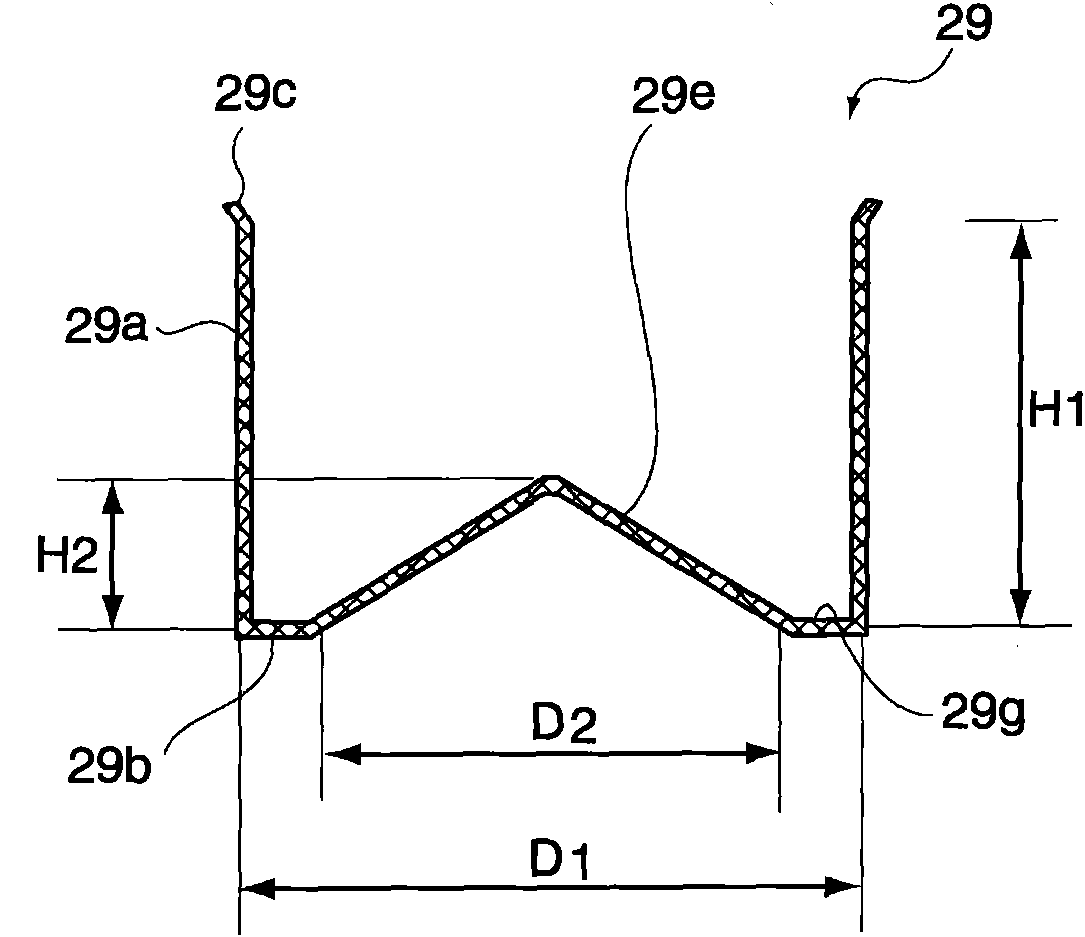

[0045] The accommodating unit 29 is formed of a mesh material and has a cylindrical portion 29a and a bottom 29b, and is installed in the accommodating space 25 so that the central portion of the bottom 29b coincides with the rotation axis (L), and accommodates a plurality of Rotate together with the rotating unit 27 in the state of the processed object 10;

[0046] a spraying unit 31, which sprays a coating treatment liquid 31a containing a coating component to a plurality of objects to be treated flowing inside the accommodation unit 29;

[0047] The heating unit 35 is configured to heat the plurality of processed objects flowing inside the housing u...

no. 2 Embodiment approach

[0151] A second embodiment is a roll coating method for coating the surfaces of a plurality of objects to be treated with a coating component using the roll coating device of the first embodiment, wherein:

[0152] While making a plurality of objects to be processed flow inside the storage unit, the coating treatment liquid is simultaneously sprayed by the spraying unit, and the coating component is cured by heating by the heating unit.

[0153] That is, in a figure 1 In the roll coating method of the predetermined roll coating device 20 shown, it is possible to simultaneously spray the coating treatment liquid by the spray unit 31 and pass through the heating unit while making a plurality of processed objects 10 flow on the bottom 29b of the housing unit 29. Since the coating component is cured by heating, the coating treatment liquid can be uniformly attached to a plurality of objects 10 to be processed, and can be cured uniformly while preventing the objects 10 from adheri...

Embodiment 1

[0201] As shown below, the effect of the height of the projection of the storage unit on the coating was confirmed by producing a covered molded article using the storage unit having the protrusions shown in Table 1, and measuring the thickness of the polyimide layer.

[0202] 1. Manufacture of coated moldings

[0203] (1) Prepare the object to be processed

[0204] First, the object to be processed is formed from a soft magnetic material into Figure 4 Shapes shown, each with an overall surface area of 10mm 2 , The coercive force is 40A / m.

[0205] In addition, when the temperature rises to about 500K, the coercive force of the object to be processed tends to decrease.

[0206] (2) Sandblasting

[0207] In addition, if Figure 5 As shown in FIG. 2 , blasting was performed using a blasting device with side peripheral walls having an octagonal rotating housing.

[0208] In this treatment, the rotating chamber was rotated at 11 rpm, and the alumina particles with an aver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com