Automobile hub spraying process

A technology for automobile hubs and processes, applied in the direction of hubs, coatings, spraying devices, etc., can solve the problem of single color of wheel hub spraying, and achieve the effect of low cost, simple process and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

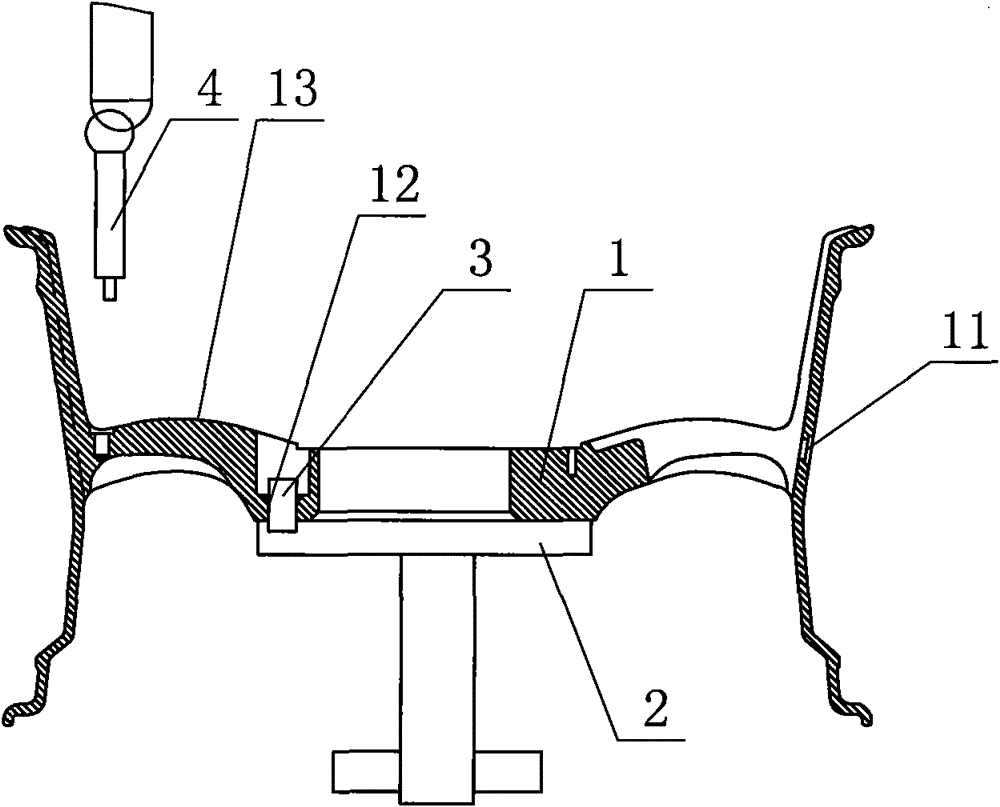

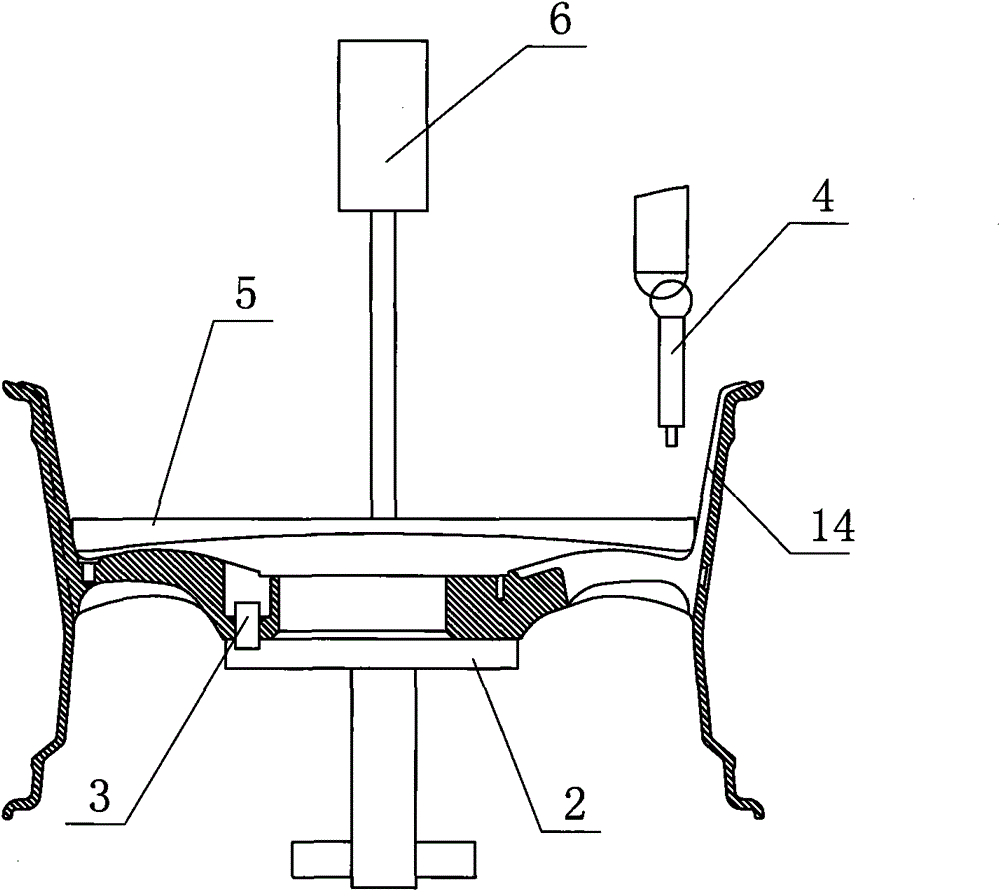

[0014] combine figure 1 with figure 2 Shown, a kind of special spraying process of automobile wheel hub of the present invention comprises the steps:

[0015] 1) Use a blocking tool to block the valve hole 11 of the automobile hub 1, then place the automobile hub on a pallet 2, and then use the positioning pin 3 to match the PCD hole 12 of the automobile hub itself to position the automobile hub on the pallet 2, Finally, the bottom of the tray is driven to rotate by the power source, and the spraying manipulator 4 is used to spray the panel surface 13; the blocking tool can use high temperature resistant plastic plugs or other special structures.

[0016] 2) Baking the paint on the panel surface 13 of the automobile wheel hub fixed on the pallet to prevent the pressure plate from being pressed down in the next process from damaging the sprayed surface on the panel surface;

[0017] 3) Cover the panel surface 13 with a pressing plate 5 matching the panel surface of the autom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com