Actuating apparatus for actuating at least one shift apparatus and method for the assembly and disassembly thereof

A technology of operating mechanism and gear shifting mechanism, which is applied in the direction of transmission, mechanical equipment, shafts and bearings, etc., to achieve the effect of less disassembly parts, high quality and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

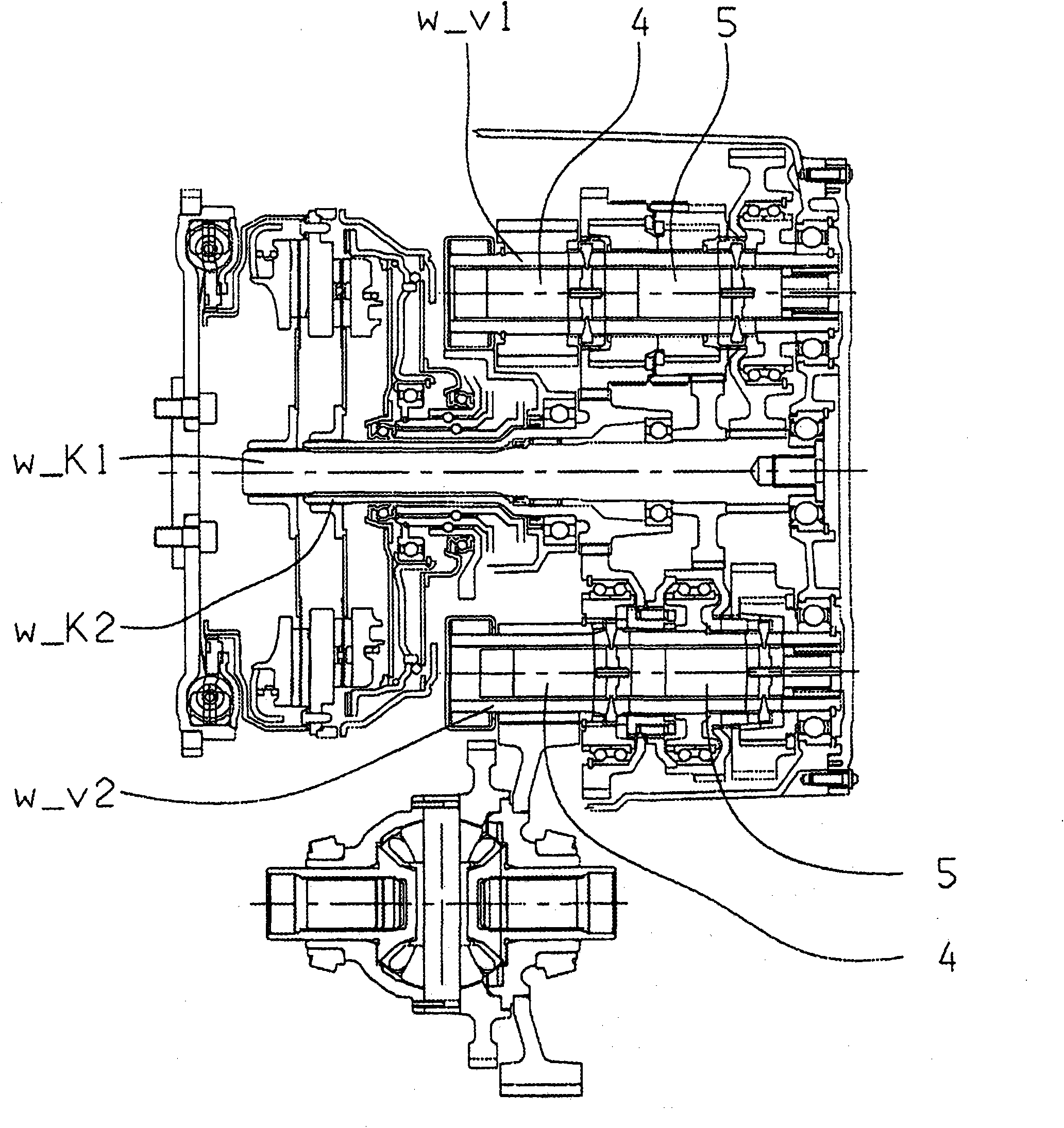

[0028] exist figure 1 As a possible field of use of the actuating mechanism proposed according to the invention for actuating at least one shifting mechanism or shifting element, a cross-sectional view of a multi-speed dual-clutch transmission in the form of an intermediate shaft is shown by way of example.

[0029]The dual clutch transmission includes two clutches, the input ends of which are connected to the drive shaft. Furthermore, a torsional vibration damper is arranged on the drive shaft. The outputs of the two clutches are each connected to one of the two concentrically arranged transmission input shafts w_K1 , w_K2 . The first transmission input shaft w_K1 is designed as a solid shaft, and the second transmission input shaft w_K2 is designed as a hollow shaft. Furthermore, two countershafts w_v1 , w_v2 are provided, which are arranged axially parallel to one another. A number of idler gears are arranged on each countershaft w_v1 , w_v2 , which mesh with fixed gears...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com