Explosion positioning method of manually made PCB (Printed Circuit Board)

A technology of PCB board and positioning method, which is applied in the direction of removing conductive materials by chemical/electrolytic methods, optical, patterned surface photoplate making process, etc., which can solve the problems of dislocation of upper and lower hole graphics, inaccurate positioning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

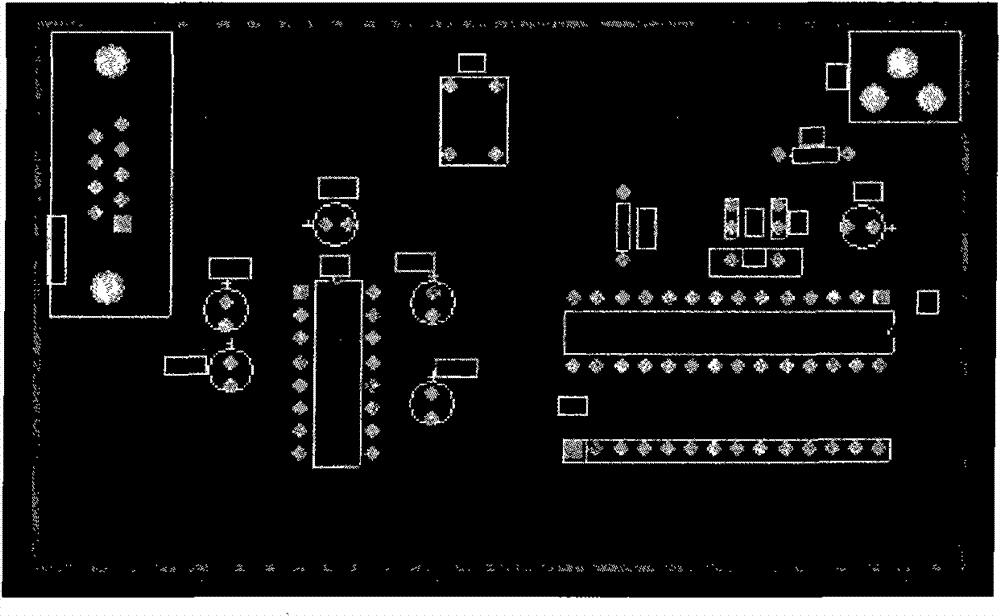

Image

Examples

Embodiment Construction

[0026] The technical scheme of the invention will be described in detail below in conjunction with the drawings:

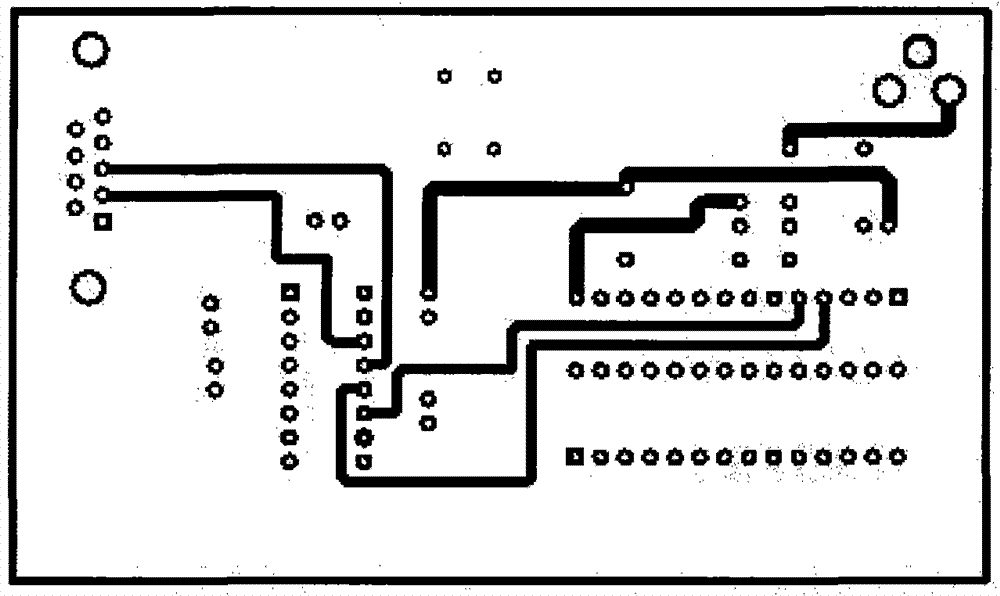

[0027] The first step: the alignment of the transparent paper hole graphics. Align the printed hole patterns on the transparent paper under the transmission of light or sunlight, and then clamp the transparent paper tightly with a clamp. Such as Figure 7 Shown.

[0028] Step 2: Fix the transparent paper and the glass plate. First, place the clipped transparent paper in the sandwich of two glass plates, then use a square to position the glass plate, and finally use the small holes on the glass plate to inject glue to position the upper and lower transparent papers on the upper and lower glass plates respectively. Structure diagram such as Figure 8 Shown.

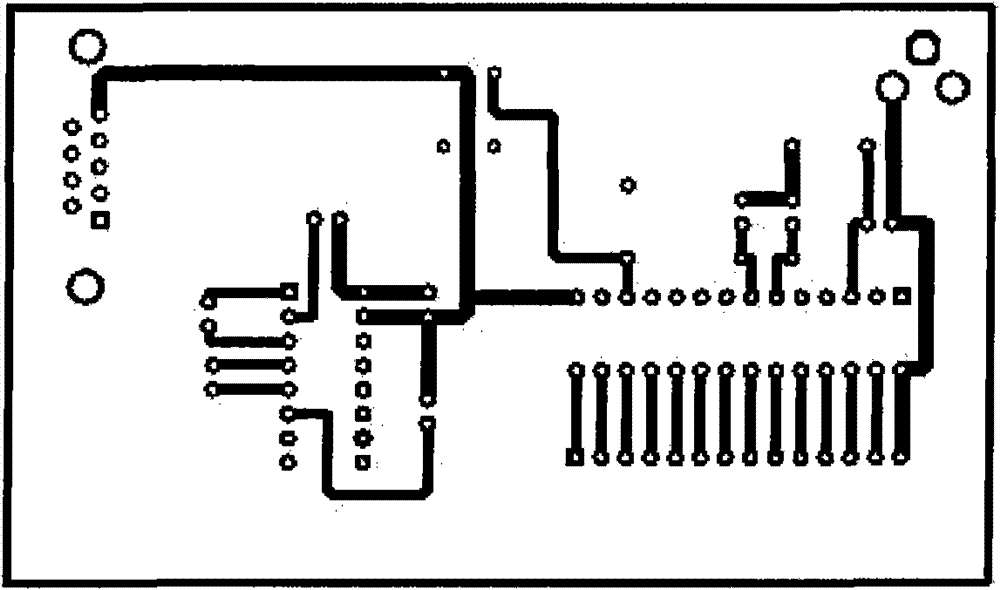

[0029] The third step: Place the PCB board. Remove the clip on the transparent paper, place the PCB board in the interlayer of the transparent paper (the upper and lower transparent paper are fixed with the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com