Unmanned helicopter tail transmission structure

An unmanned helicopter and tail drive technology, which is applied in the direction of motor vehicles, aircraft power transmission, and aircraft power devices, etc., can solve the problems of tail drive shaft vibration, tail drive shaft deformation, easy misalignment, etc., and achieve easy installation and small deformation , the effect of reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below with reference to the accompanying drawings and embodiments.

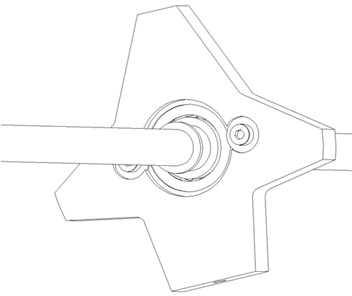

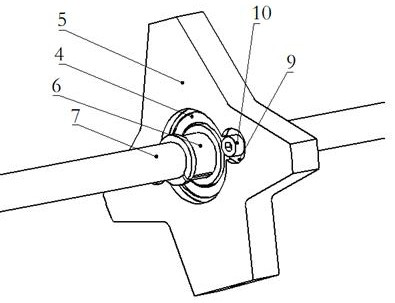

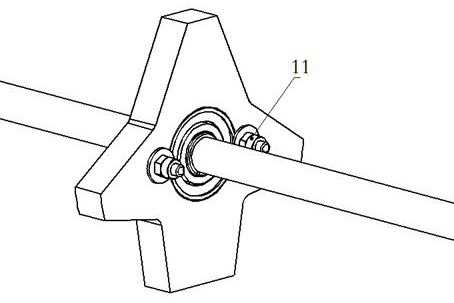

[0032] This embodiment provides a tail drive structure of an unmanned helicopter, see appendix figure 1 , including: coupling rear flange 1, coupling front flange 2, coupling 3, deep groove ball bearing 4, tail shaft support 5, tail shaft positioning sleeve 6, tail shaft 7, tail shaft The transmission shaft connecting piece 8 and the support cylinder of the tail transmission shaft;

[0033] One end of the tail shaft 7 is connected with the power unit of the unmanned helicopter through the coupling 3, and the other end of the tail shaft 7 is connected with the tail rotor of the unmanned helicopter through the tail shaft connector 8;

[0034] Among them, see appendix figure 2 , the coupling 3 adopts a hexagonal plum blossom coupling, and the two ends of the coupling 3 are respectively connected with the power unit and the tail shaft 7 through the rear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com