Golf club head and method for manufacturing the same

A golf club and manufacturing method technology, applied to golf balls, golf clubs, rackets, etc., can solve the problems of generating gaps and steps, not fully considering positioning, etc., and achieve the effect of preventing dislocation

Inactive Publication Date: 2010-11-10

DUNLOP SPORTS CO LTD

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, such technology does not fully consider the positioning of the two members b1, b2 in the vertical direction (the direction of symbol f in FIG. 20 ).

Therefore, gaps and steps may occur on the top surface, and there is still room for improvement

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

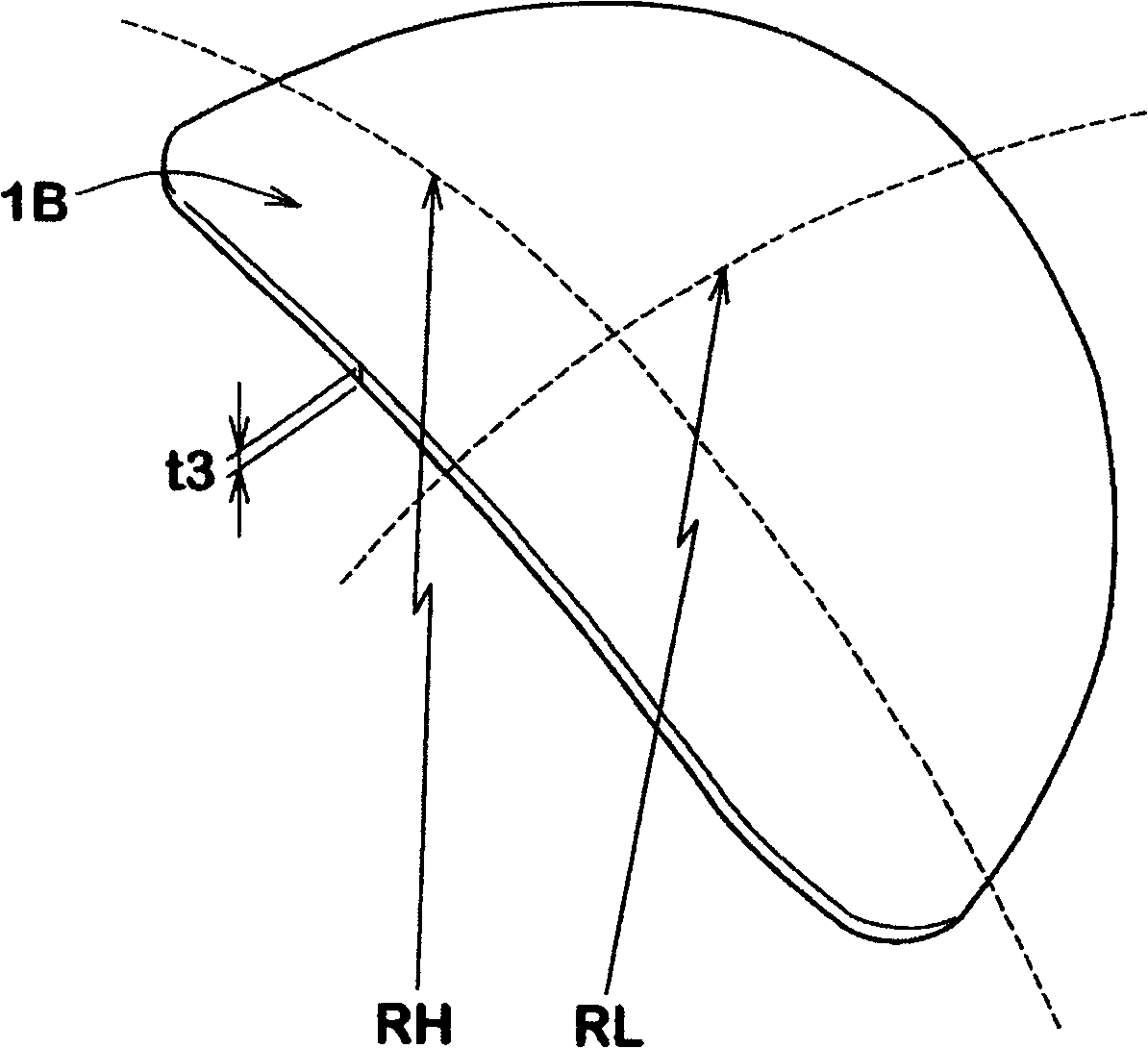

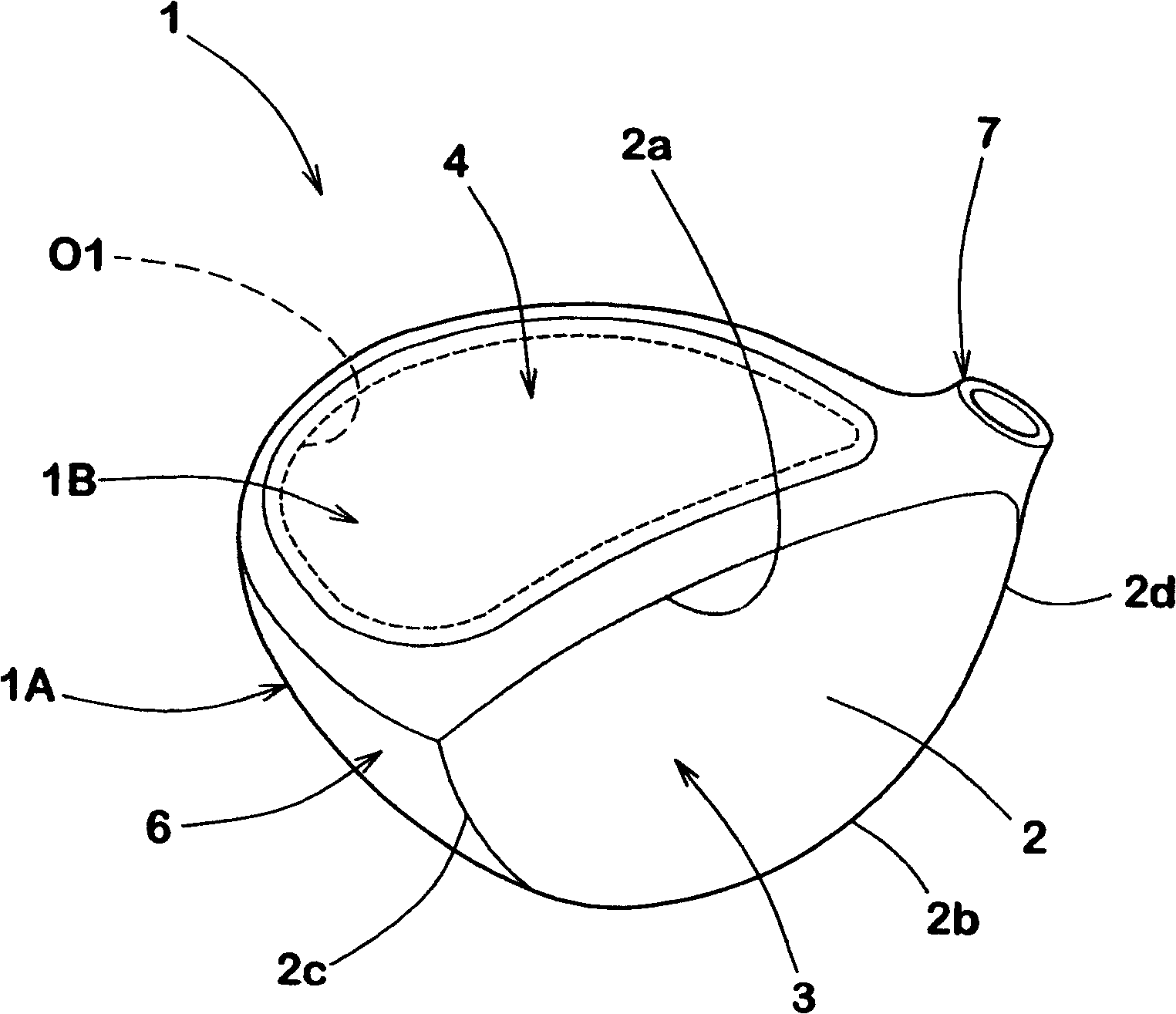

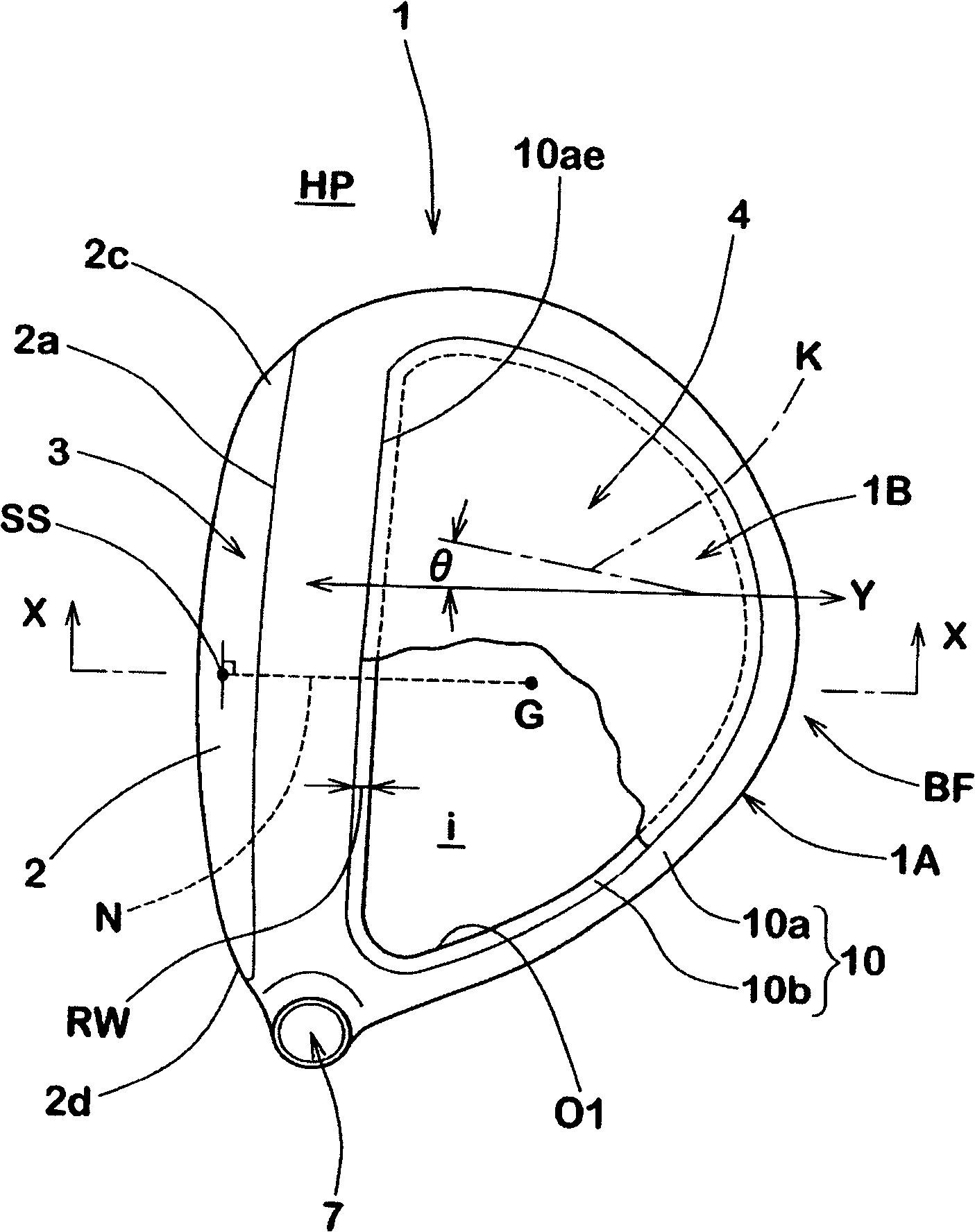

A method for manufacturing golf club head is provided in present invention by which degraded product can be prevented when manufacturing. The golf club head comprises: a head body (1A) made of metal material having at least one opening part (O1) at top face part thereof; a top face part component (1B) made of metal material and fixed on the head body (1A). The head body (1A) comprises: a supporting part (10b) for supporting the inner face (1Bi) circumference part of the top face part component around the opening part; a projecting part (10c) projecting outward which is provided along the outer circumference (1Be) of the top face part component (1B). The method further includes the following steps: a temporary fixing step by which the top face part component (1B) is supported and covered by the supporting part (10b) so as to plastically deform the projecting part (10c), thus a press bending part (10d) is formed which sandwiches the top face part component (1B) between the supporting part (10b) and press bending part; a formal fixing step for fixing the head body (1A) with the top face part component (1B) after the temporary fixing step.

Description

Golf club head and manufacturing method thereof technical field The present invention relates to a golf club head capable of reducing the occurrence of defective products during manufacture and a method for manufacturing the same. Background technique Conventionally, a golf club head has been proposed in which a head body having an opening in the top surface and a top surface member that is made of a metal material different from the head body and closes the opening are provided. A hollow structure to be joined. However, in such a club head, misalignment is likely to occur when the club head body and the crown surface member are joined, and as a result, the club head is prone to unsightly appearance and durability degradation due to poor joining. In addition, for example, such a technique has also been proposed. As shown in FIG. 19(A), (B) and the C-C section of FIG. 19(B), that is, as shown in FIG. In the case of head a, a convex part c is provided at the joint end of ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): A63B63/04A63B53/04A63B102/32

Inventor 杉本靖司

Owner DUNLOP SPORTS CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com