Porous rare-earth metal-organic framework material, preparation method and application thereof in natural gas storage

A rare earth metal and organic framework technology, which is applied in the fields of material chemistry, organic chemistry, and inorganic chemistry, can solve the problems of not meeting technical requirements and the need for development of carrier materials, and achieve the effect of good storage performance and high thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The porous rare-earth metal-organic framework can be synthesized by a variety of methods, including hydrothermal method, solvothermal method, and medium-temperature solvent evaporation method. The medium-temperature solvent evaporation method is the most economical and feasible method. The specific steps are as follows:

[0045] Step 1, dissolving the nitrate or halide of the rare earth metal and the organic ligand BTC with a molar ratio of 0.2 to 5:1 in a mixed solvent composed of an organic solvent and water, and the molar ratio of the organic solvent to water is 5 to 10: 1. The concentration of the organic ligand is 1 x 10 -2 ~10mol / L;

[0046] Step 2, reacting the above solution at a temperature of 4°C to 180°C for 1 to 72 hours;

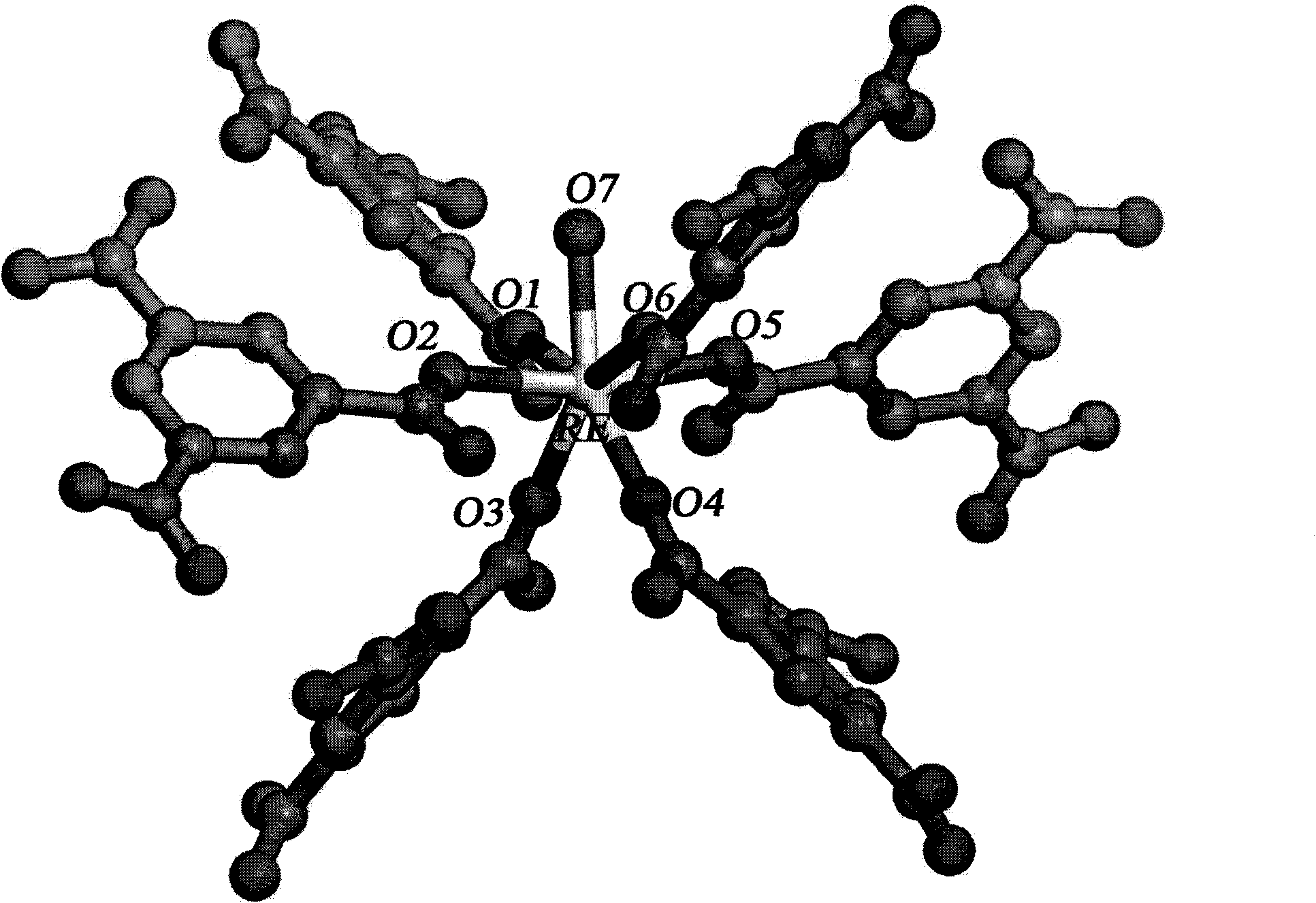

[0047] Step 3, wash with ethanol several times, and dry at 20°C to 150°C to obtain colorless crystals of rare earth metal-organic framework materials, whose general formula is RE(BTC)H 2 O, the yield calculated by organic ligand is 30~8...

Embodiment 1

[0057] (1) In a glass beaker, put 10g of Y(NO 3 ) 3 ·6H 2 O, 5g H 3 Dissolve BTC in a mixed solvent of 50mL DMF (N,N'-dimethylformamide) and 10mL water, stir for 1 hour to dissolve completely, and seal with plastic wrap; place the above solution in an oven at 85°C for 12 hours Afterwards, filter (medium-speed qualitative filter paper, glass funnel normal pressure filter), wash 3 times with 20ml ethanol, dry at 60 ℃, obtain colorless microcrystal, yield rate is 73% (calculated by H3BTC). The cell parameters are 10.2908, 10.2908, 17.4730, 90.00, 90.00, 90.00;

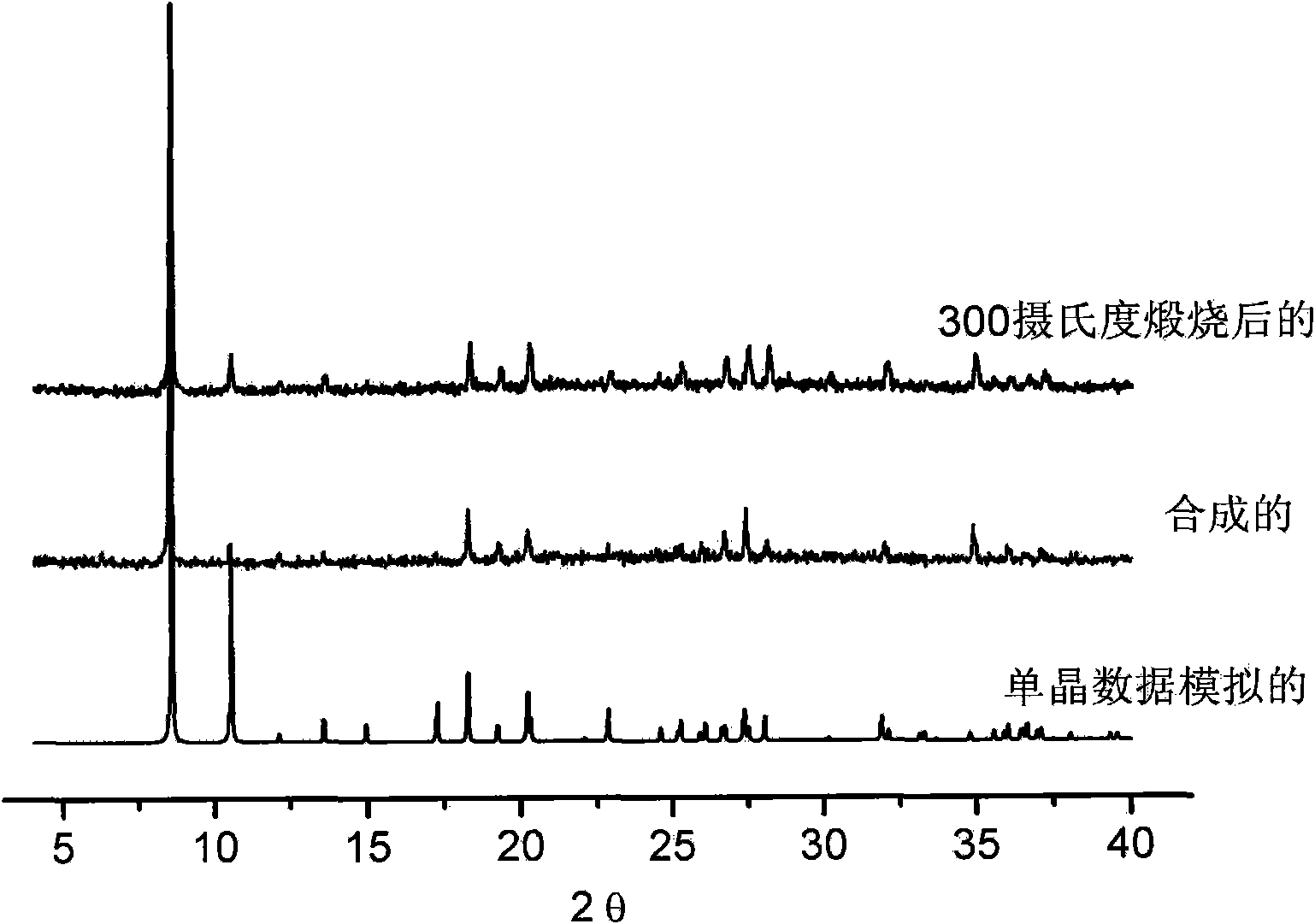

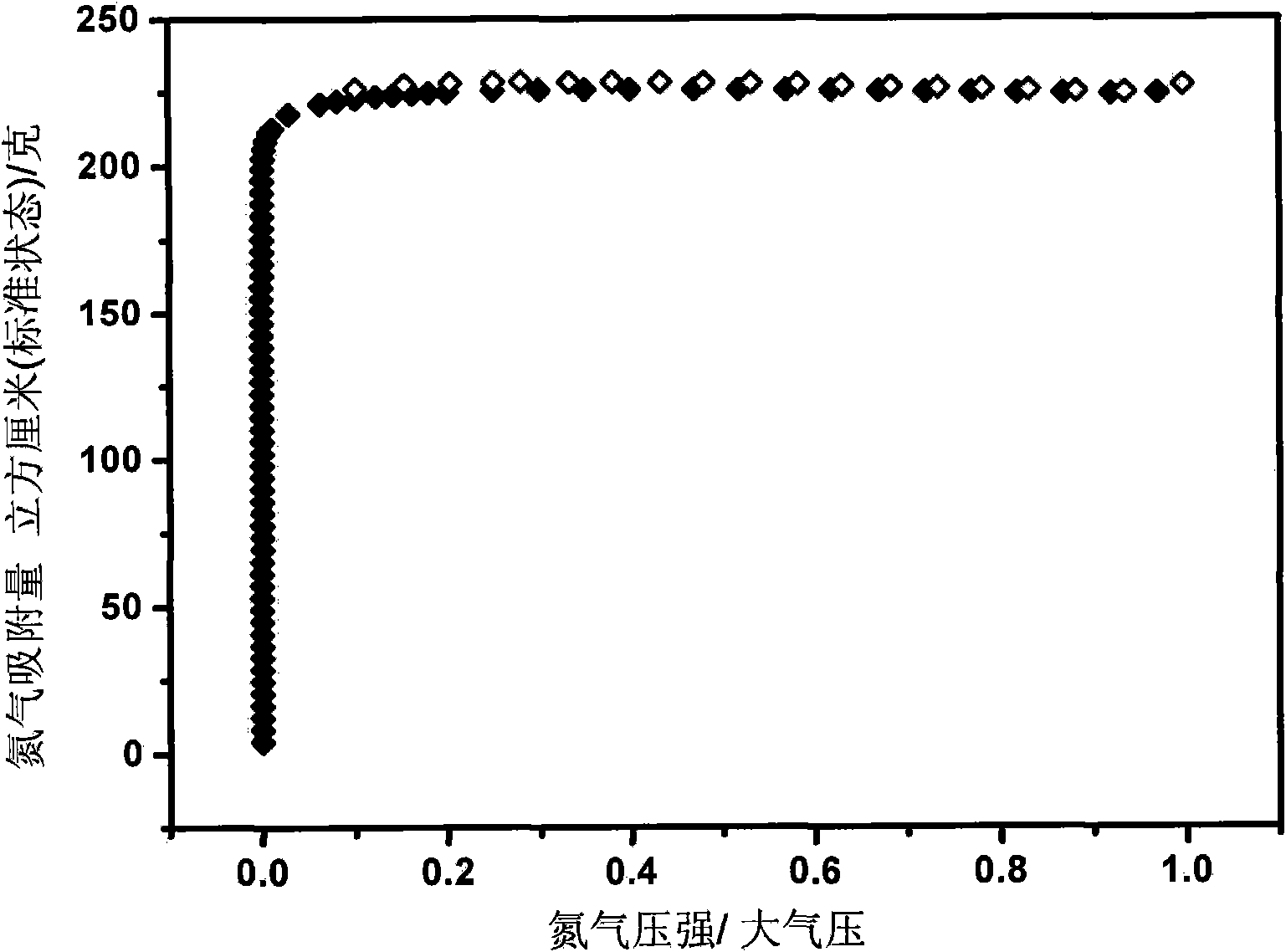

[0058] (2) Soak the microcrystalline product obtained in step (1) in 50 mL of methanol for two days, replace the methanol once a day, then filter, and dry at 60° C. The obtained product was calcined at 300° C. for 4 hours. like figure 2 As shown, from bottom to top, the XRD spectrum of the rare earth metal organic framework material simulated by the Materials Studio 4.0 software from the single crystal structure da...

Embodiment 2

[0062] The mixed solution in step (1) of Example 1 was transferred to a stainless steel reaction kettle, the temperature of the oven was changed to 180° C., and other conditions were kept constant to obtain the same material as described in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com