Method for controlling material flow balance without quantitative feed pipe

A flow-balanced, quantitative tube technology, applied in conveyor control devices, conveyor objects, transportation and packaging, etc., can solve the requirements that cannot meet the requirements of large-moisture cut tobacco flow control, the material flow is difficult to achieve balanced requirements, and the electronic scale belt cut tobacco Uneven and other problems, to achieve the effect of good promotion and application prospects, good industrial application value, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

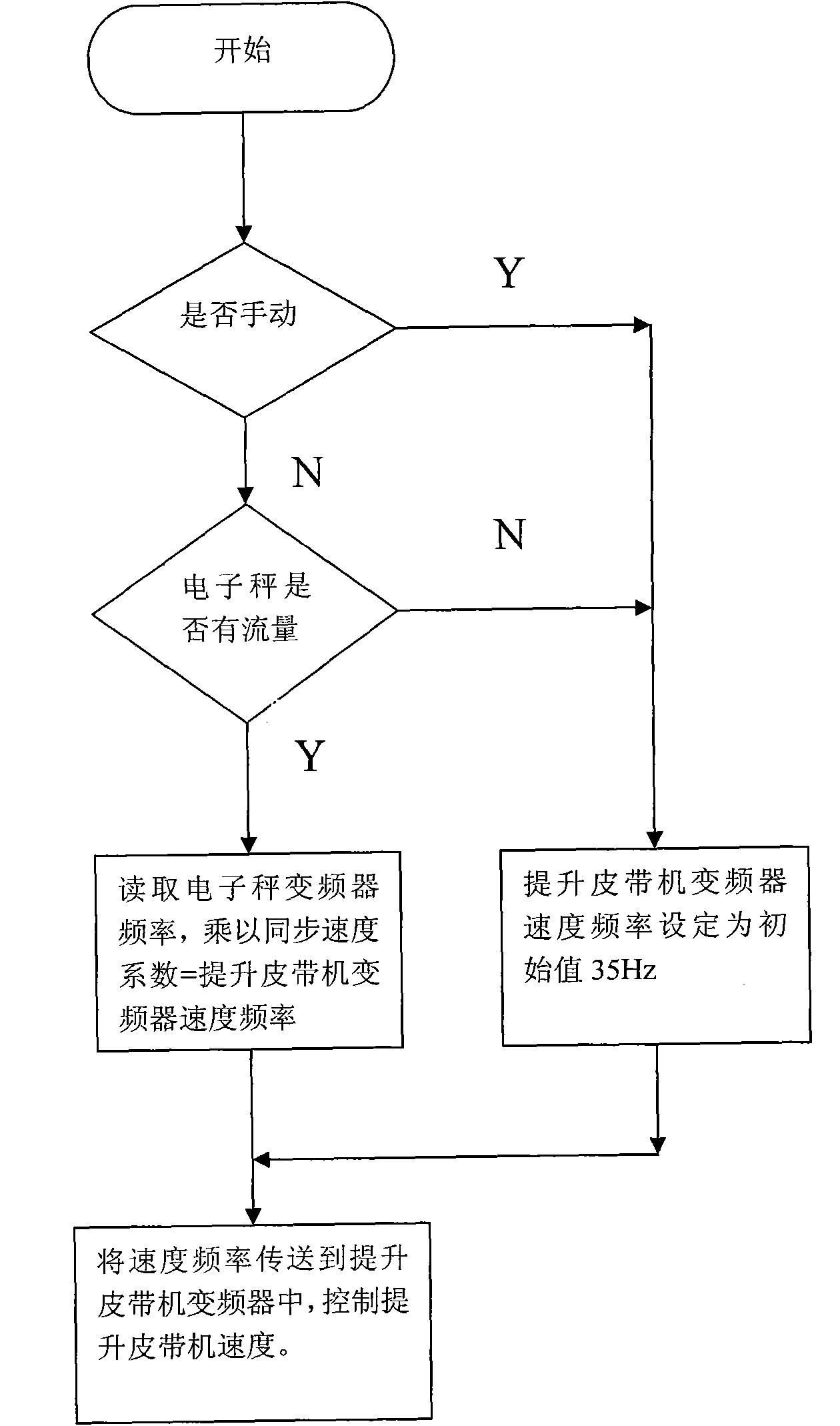

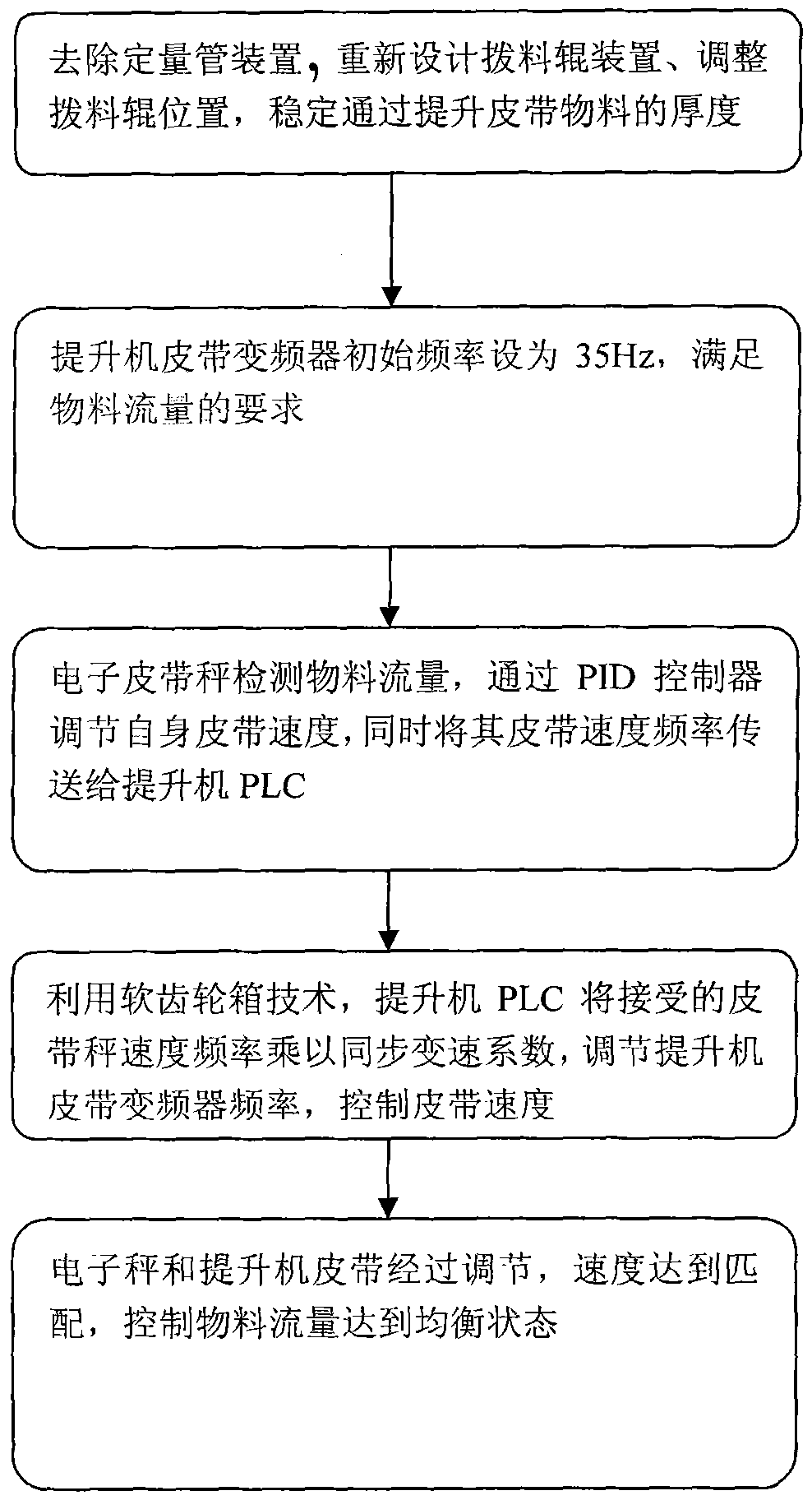

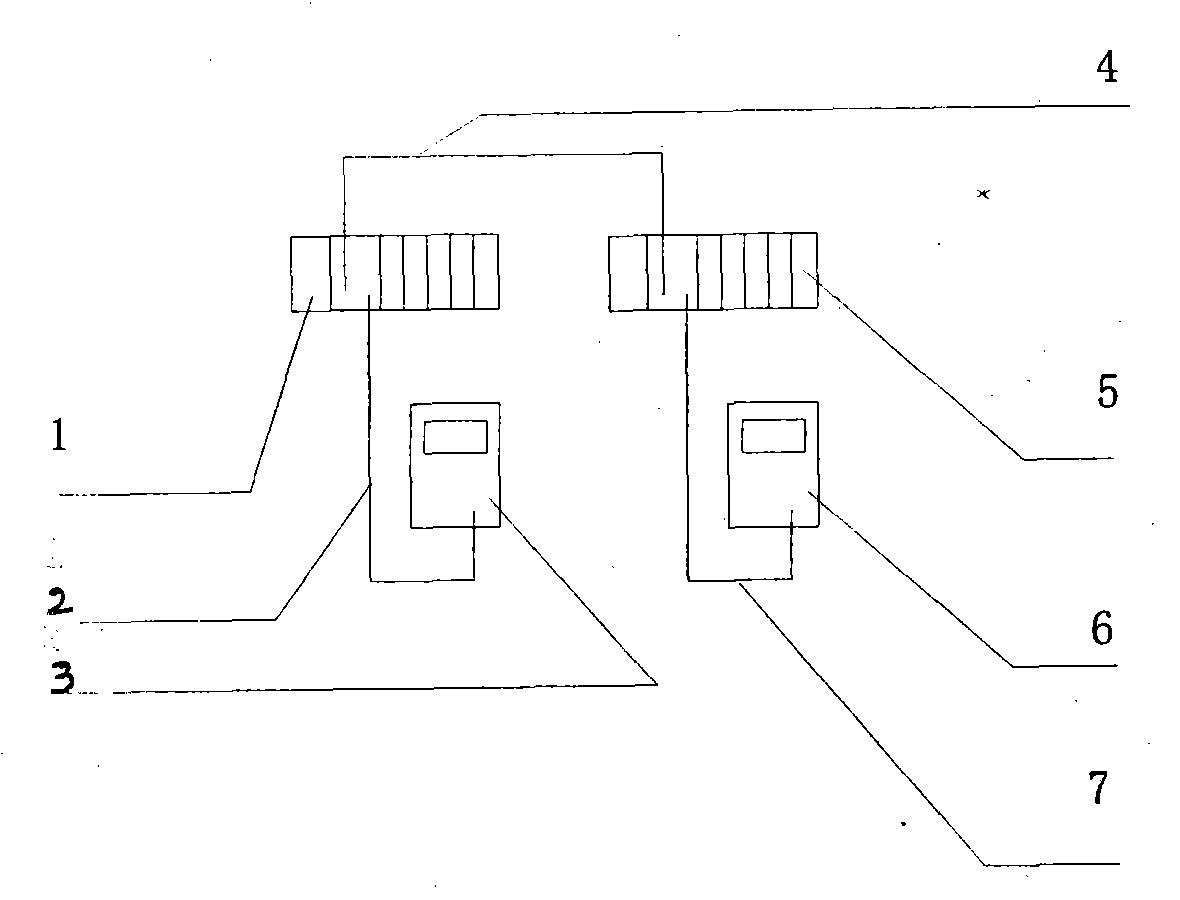

[0013] 1. In traditional electronic scales and warehouse-type feeder devices, metering tubes and shifting roller mechanisms are usually used to sort out and control the flow of shredded tobacco. Because the moisture content of the shredded tobacco material is relatively high, the shredded tobacco often agglomerates due to its own weight extrusion when passing through the metering pipe. The process adjusts the length, distribution density, and relative position of the rake nails on the material roller, and the relative position between the material roller and the belt. After testing, it is finally determined that the length of the rake nails is 10 cm, and 8 rows are evenly distributed along the circumference of the material roller. A row of 19 evenly distributed rakes strengthens the combing effect of the feed roller on the shredded tobacco, and can well control the thickness and uniformity of the shredded tobacco on the belt; The distance is 8 mm, so as to ensure that the freq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com