Arc extinguish chamber with high current-carrying capability for high-voltage switch equipment

A high-voltage switch and arc-extinguishing chamber technology, applied in the field of high-voltage equipment, can solve the problems of difficulty in increasing the rated current level, large heat generation, small conductive cross-section, etc., to improve current conditions and heat dissipation conditions, improve material selection, reduce loops The effect of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

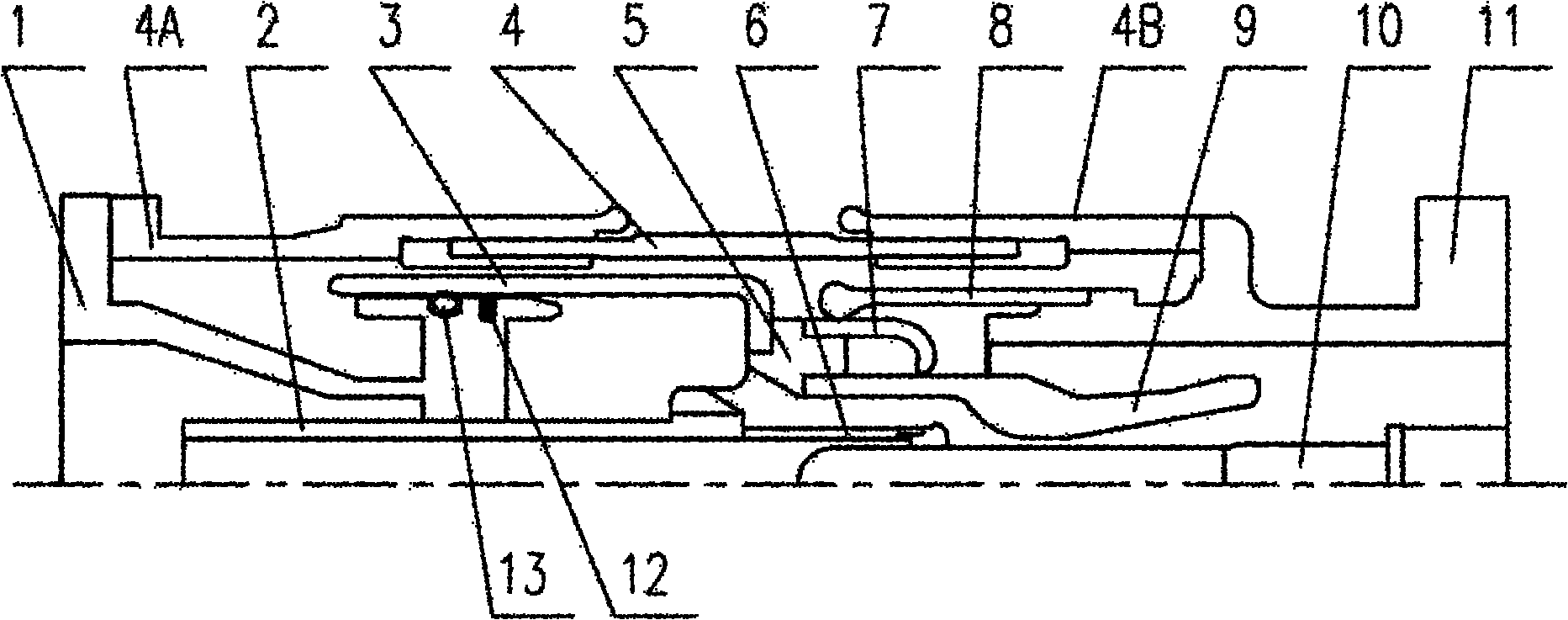

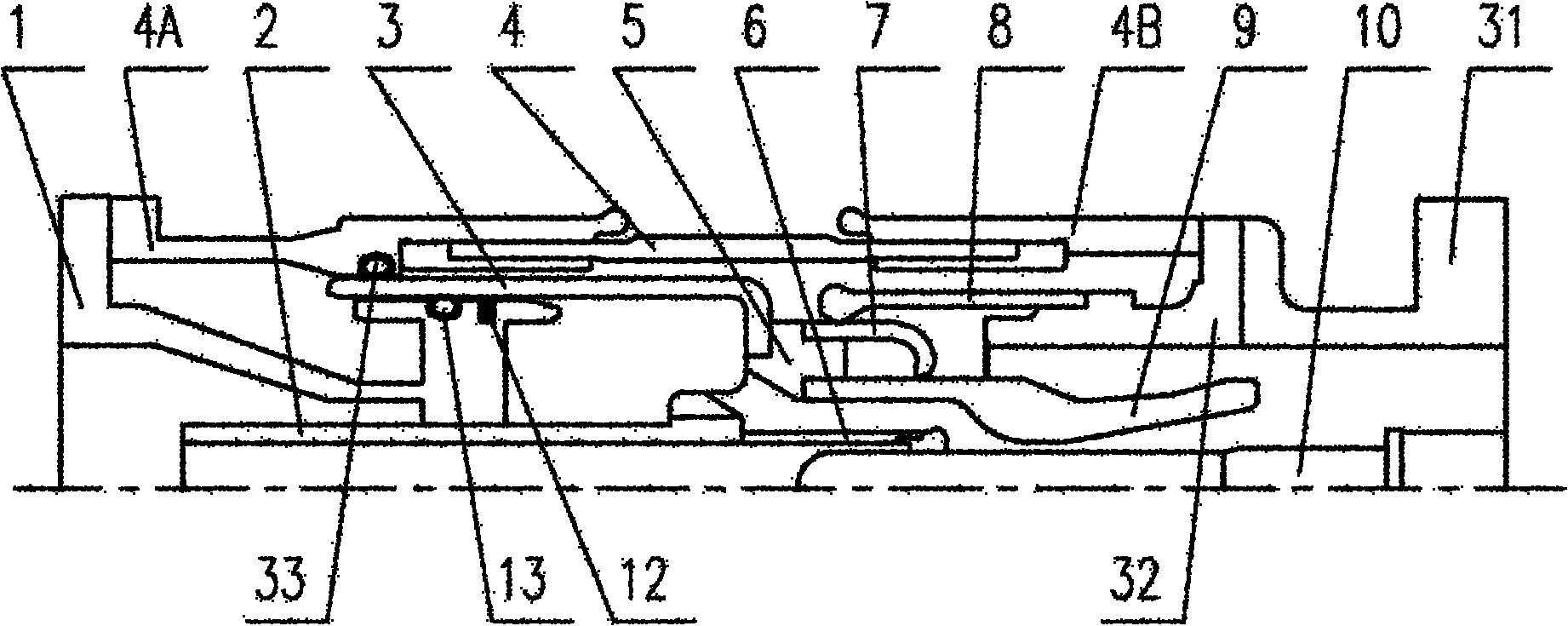

[0056] see figure 2 , an arc extinguishing chamber in a circuit breaker housing filled with SF6, its structure is as follows: the outermost layer of the arc extinguishing chamber is an insulating support 4 with metal inserts at both ends, including its moving end Metal insert 4A, static end metal insert 4B (same as the original design).

[0057] The static end metal insert 4B of the insulating support is connected with the static contact system of the arc extinguishing chamber, the static contact system is coaxial with the insulating support 4, including the transition connected with the static end metal insert 4B of the insulating support 4 Conductor 32 , static contact seat 31 , static main contact 8 and static arc contact 10 .

[0058] The metal insert 4A at the moving end of the insulating support is connected to the moving contact system of the arc extinguishing chamber. The moving contact system is coaxial with the insulating support 4 and includes a gas pressure pisto...

Embodiment 2

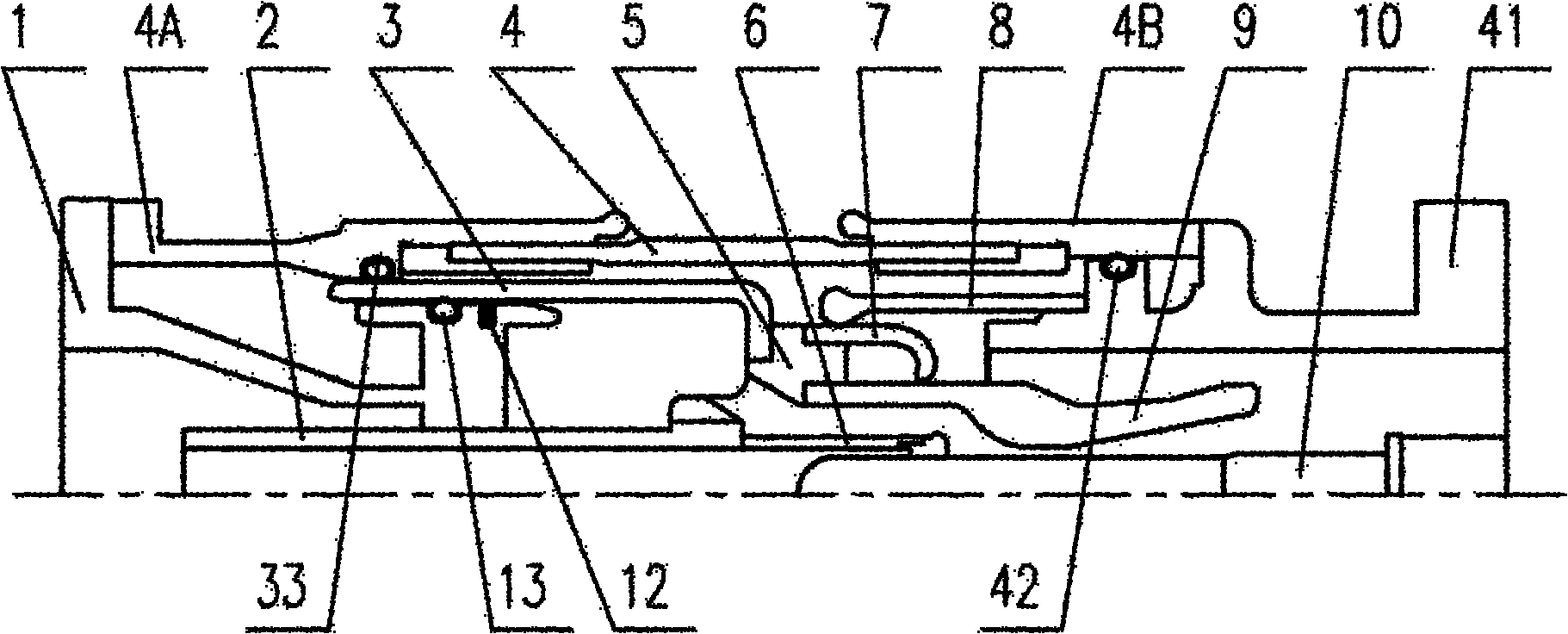

[0066] see image 3 , an interrupter that is filled with SF 6 In the circuit breaker housing, its structure is as follows: the outermost layer of the arc extinguishing chamber is an insulating support 4 with metal inserts at both ends, including its moving end metal insert 4A, static end metal insert 4B.

[0067] The metal insert 4B at the static end of the insulating support is connected to the static contact system of the arc extinguishing chamber. The static contact system is coaxial with the insulating support 4 and includes a static contact connected to the metal insert 4B at the static end of the insulating support 4. The head seat 41, the static main contact 8, the static arc contact 10, and the third contact 42 (which may be spring contacts or strap contacts or self-powered contacts).

[0068] The structure of the moving end of the arc extinguishing chamber is exactly the same as that of Embodiment 1.

[0069] The conductive circuit in Embodiment 2 is constructed as...

Embodiment 3

[0075] see Figure 4 , Embodiment 3 is basically the same as Embodiment 2, except that the second contact 13 in Embodiment 2 is removed. Because most of the current flowing from the cylinder 3 to the moving side will flow through the first contact 33 through the metal insert 4A at the moving end and out of the arc extinguishing chamber, its implementation effect, characteristics and advantages are basically the same as those in Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com